Machining method of miniature metal bipolar plate based on plasticine support

A metal bipolar plate and processing method technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problem of affecting the shape and accuracy of the flow channel of the metal bipolar plate, reducing the machining accuracy of the metal bipolar plate, increasing the processing steps and Cost and other issues, to reduce processing time and cost, reduce forming defects, good formability and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

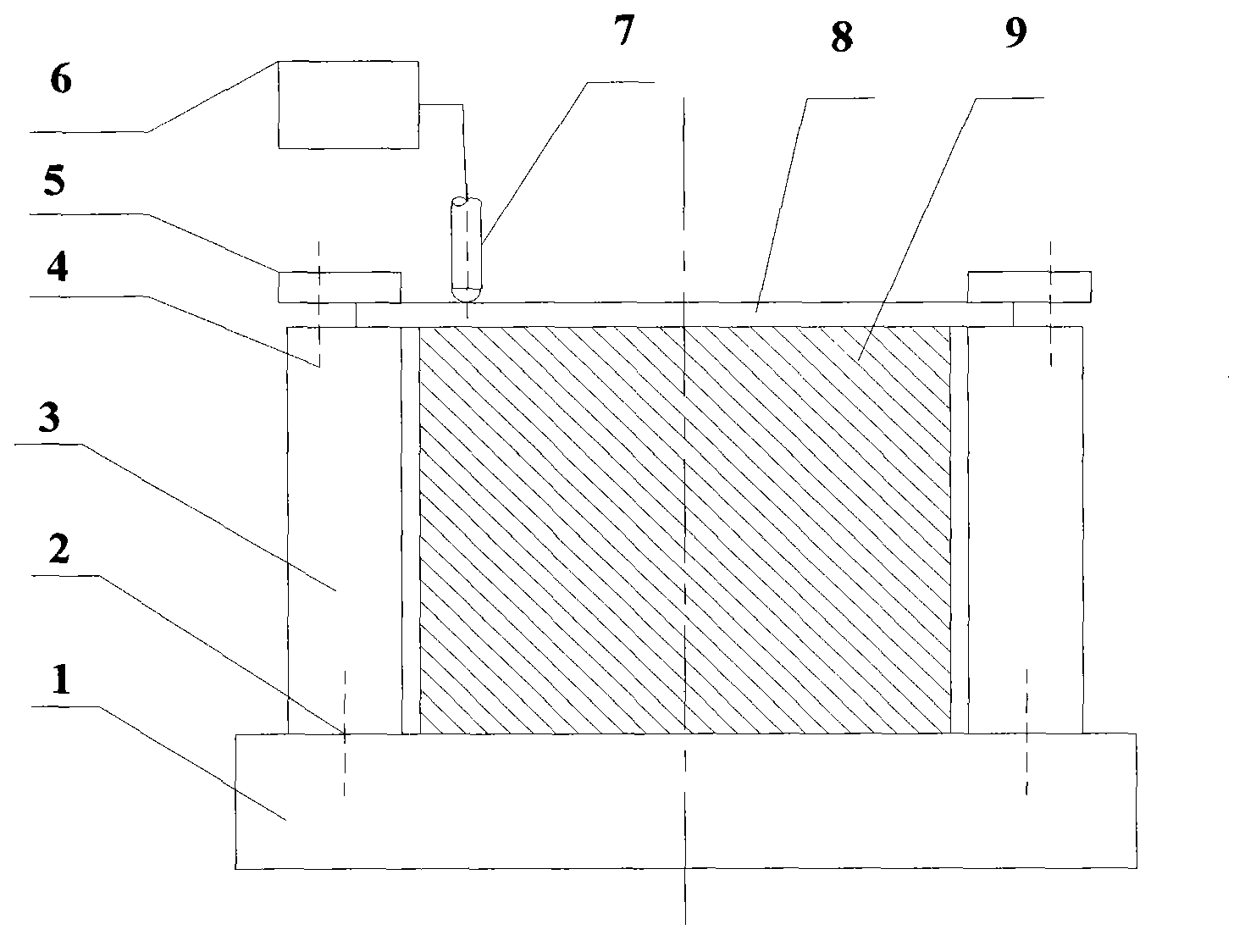

[0022] Combine below figure 1 The specific details and working conditions of the processing of the miniature metal bipolar plate supported by plasticine are described in detail with specific examples. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

[0023] The method for processing miniature metal bipolar plates based on plastic clay support proposed by the present invention firstly fixes the workbench 1 horizontally at an appropriate position, properly adjusts the size of the support seat 3 according to the size of the metal plate to be processed, and places the adjusted support The seat 3 is placed horizontally on the workbench 1, and the positioned support seat 3 and the workbench 1 are connected and fixed with the connecting screw 4; the ratio of the plastic clay is selected according to the strength of the metal plate for processing the flow channel, and the raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com