Preparation method for high-conductivity lithium titanate cathode material of lithium battery

A high-conductivity, negative-electrode material technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low compaction density and high energy consumption, and achieve the effect of increasing compaction density, improving roasting efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

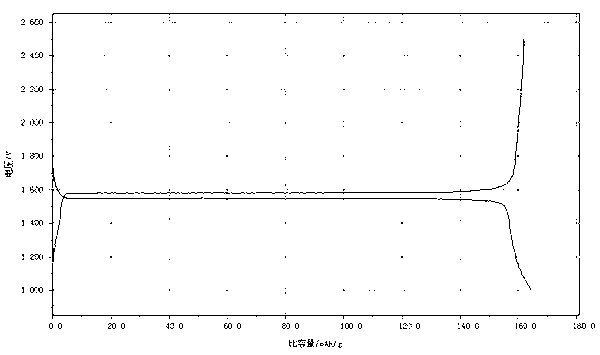

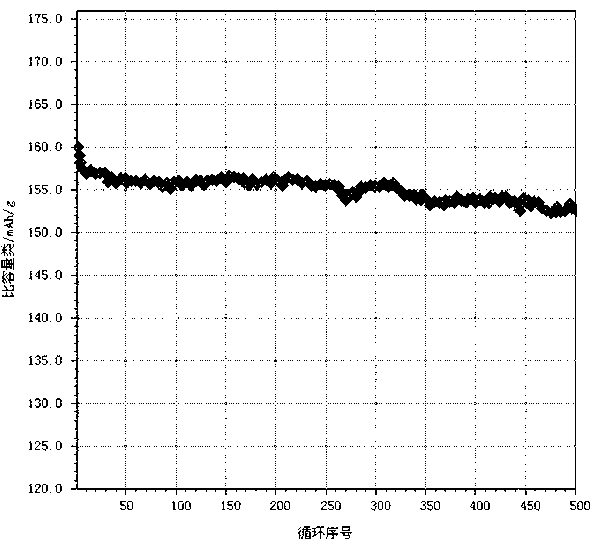

Image

Examples

Embodiment 1

[0034] A method for preparing a high-conductivity lithium titanate negative electrode material for a lithium battery, comprising the following process steps:

[0035] A. Weigh the lithium-containing compound and the titanium-containing oxide respectively in the ball mill tank according to the ratio of Li:Ti=0.8:1 molar ratio between lithium ion and titanium ion, add deionized water as the dispersant, and carry out ball milling to obtain uniform mixing mixed slurry;

[0036] B. Transport the mixed slurry obtained in step A to a spray dryer for granulation and drying to obtain a dry precursor powder;

[0037] C. Put the precursor powder obtained in step B into a high-temperature furnace for roasting. First, raise the temperature from room temperature to 450°C at a rate of 1°C / min and keep it for 4 hours; then follow a rate of 1°C / min. Heating rate, the temperature was raised to 750°C and kept for 4 hours; finally cooled naturally to obtain the spinel lithium titanate material Li ...

Embodiment 2

[0042] A method for preparing a high-conductivity lithium titanate negative electrode material for a lithium battery, comprising the following process steps:

[0043] A. Weigh the lithium-containing compound and the titanium-containing oxide respectively in the ball mill tank according to the ratio of Li:Ti=0.85:1 molar ratio between lithium ion and titanium ion, add deionized water as the dispersant, and carry out ball milling to obtain uniform mixing mixed slurry;

[0044] B. Transport the mixed slurry obtained in step A to a spray dryer for granulation and drying to obtain a dry precursor powder;

[0045] C. Put the precursor powder obtained in step B into a high-temperature furnace for roasting. First, raise the temperature from room temperature to 650°C at a heating rate of 10°C / min and keep it for 10 hours; then follow a heating rate of 10°C / min. Heating rate, the temperature was raised to 950°C and kept for 10 hours; finally cooled naturally to obtain the spinel lithiu...

Embodiment 3

[0050] A method for preparing a high-conductivity lithium titanate negative electrode material for a lithium battery, comprising the following process steps:

[0051] A. Weigh the lithium-containing compound and the titanium-containing oxide respectively in a ball mill jar according to the molar ratio of lithium ion and titanium ion as Li:Ti=0.82:1, add deionized water as a dispersant, and perform ball milling to obtain a uniform mixture mixed slurry;

[0052] B. Transport the mixed slurry obtained in step A to a spray dryer for granulation and drying to obtain a dry precursor powder;

[0053] C. Put the precursor powder obtained in step B into a high-temperature furnace for roasting. First, raise the temperature from room temperature to 550°C at a heating rate of 5.5°C / min and keep it for 7 hours; then follow the heating rate of 5.5°C / min Heating rate, the temperature was raised to 850°C and kept for 7 hours; finally cooled naturally to obtain the spinel lithium titanate mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com