Intensive packaging method of LEDs

A technology of light-emitting diodes and packaging methods, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of low production efficiency, packaging methods that are difficult to change mass production modes, high equipment and mold costs, and achieve production input costs. Low-cost, fast mass production and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with the given examples, but not limited thereto.

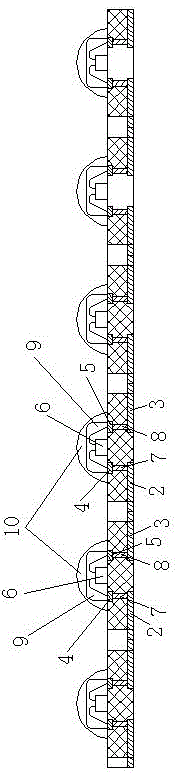

[0018] An intensive packaging method for LED light-emitting diodes, the substrate of several light-emitting LED chips with bonding wires regularly arranged and bonded is used as the processing object (such as figure 1 Shown); with the stencil and scraper as the processing technology equipment, and its: the steps of the packaging are:

[0019] Step a, sticking the screen plate on the substrate, and all the through holes of the screen plate correspond to the several light-emitting LED chips on the substrate one by one, and the light-emitting LED chips are higher than the upper surface of the screen plate;

[0020] Step b. Pour the transparent glue containing fluorescent powder on the screen, and then spread it evenly with a scraper. The transparent glue containing fluorescent powder is coated on the periphery of each light-emitting LED chip on the substrate, so that e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com