Station device for powder coating of energy-saving lamps

An energy-saving lamp and station technology, which is applied in the application of luminescent coatings, tube/light screen manufacturing, etc., can solve the problems of low slurry outflow, low recovery and utilization rate of slurry, and inability to effectively control the thickness of powder coating. Easy to adjust, convenient upper and lower tube effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

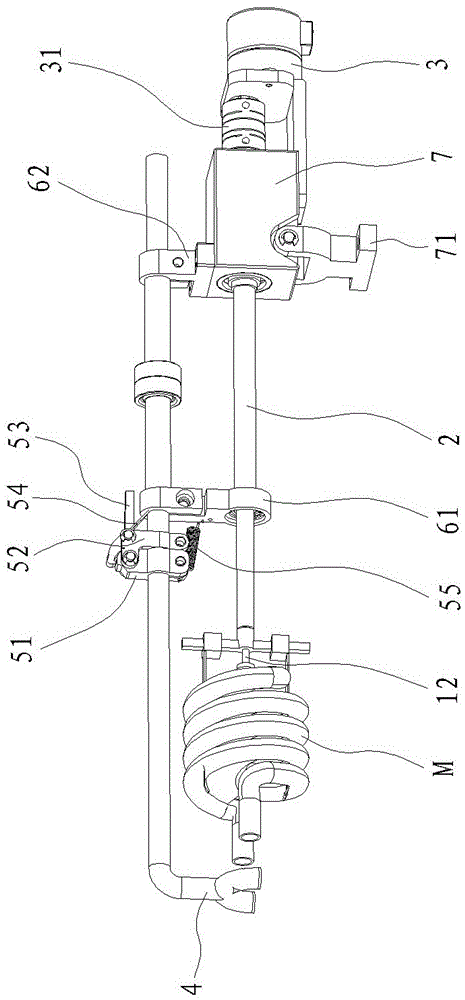

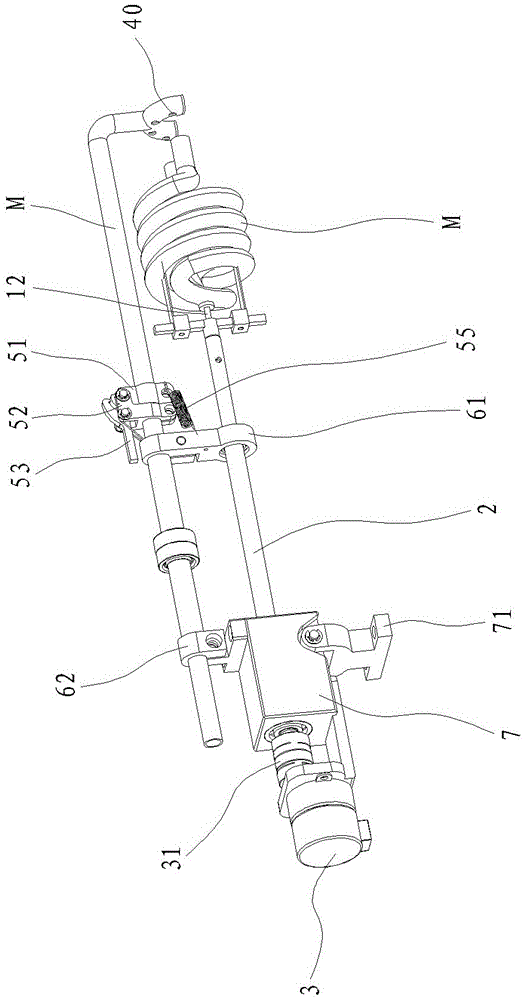

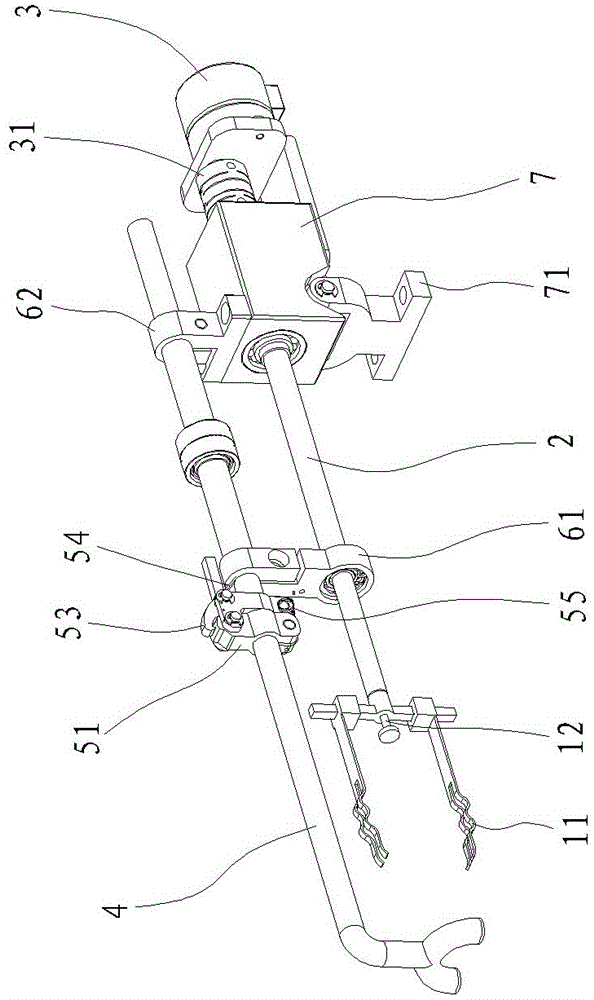

[0029] Example: see Figure 1 to Figure 5 , a station device for powder coating of an energy-saving lamp, comprising a station frame 1, a station rod 2, a drive motor 3 and a blowpipe 4, wherein:

[0030] A station frame 1, which fixes the lamp tube M and makes the lamp tube mouth face outward, and the station frame 1 is connected with the station rod 2;

[0031] The station rod 2 is driven by the drive motor 3 provided at the rear end and drives the station frame to rotate. The center axis of the front end of the station rod is provided with a shaft hole for accommodating the limit rod 12. The limit rod can move along the working direction. The position rod moves vertically;

[0032] The blowing pipe 4 is arranged in parallel with the station bar 2 and fixed as a whole by a connecting piece. The blowing pipe extends forward to the front end of the station frame and is bent to form a blowing port 40. Powder job.

[0033] see Figures 1 to 5 The blowing pipe 4 of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com