Silencing box body for box-type transformer with modular structure

A box-type transformer and box body technology, applied in transformer/inductor casing, transformer/inductor noise damping, substation/power distribution device casing, etc., can solve the problem of serious reverberation sound of the box body, short circuit of air flow, and heat out of the box To solve the problem of body and other problems, to achieve the effect of convenient transportation and on-site installation, enhanced rigidity and sound insulation, and eliminated low-frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to more clearly understand the purpose, technical solutions and beneficial effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

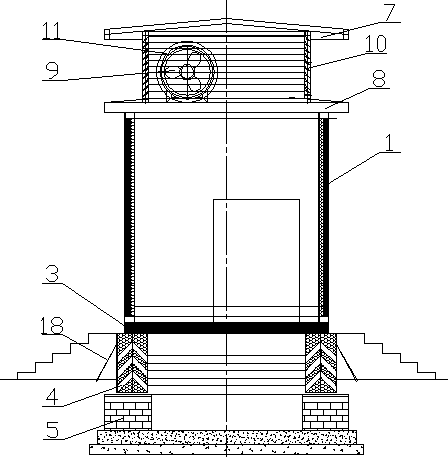

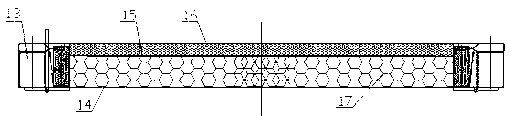

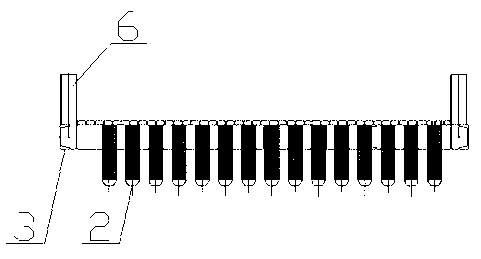

[0030] Such as figure 1 As shown in Figure 5, a box-type transformer mute box with a modular structure includes a double-layer top cover module, a resonance sound-absorbing wall 1 and a door, a noise-absorbing fence 2 and a bottom beam connected below the double-layer top cover module 3. And the box foundation 5 with the air inlet muffler 4, the bottom beam 3, the muffler fence 2 and the box foundation 5 are fixed by the positioning connecting rod 6; the double-layer roof module includes the top of the box The cover 7 and the lower top cover 8 of the box connected with the resonance sound-absorbing wall 1, the outer layer of the upper top cover 7 and the lower top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com