Quick test technique for electrochemical performances of carbon anode materials

A carbon negative electrode material and electrochemical technology, which is applied in the field of rapid testing technology for the electrochemical performance of carbon negative electrode materials, can solve the problems of reduced success rate, high cost, and long cycle, and achieve the goal of shortening the test cycle, saving test costs, and effective contact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

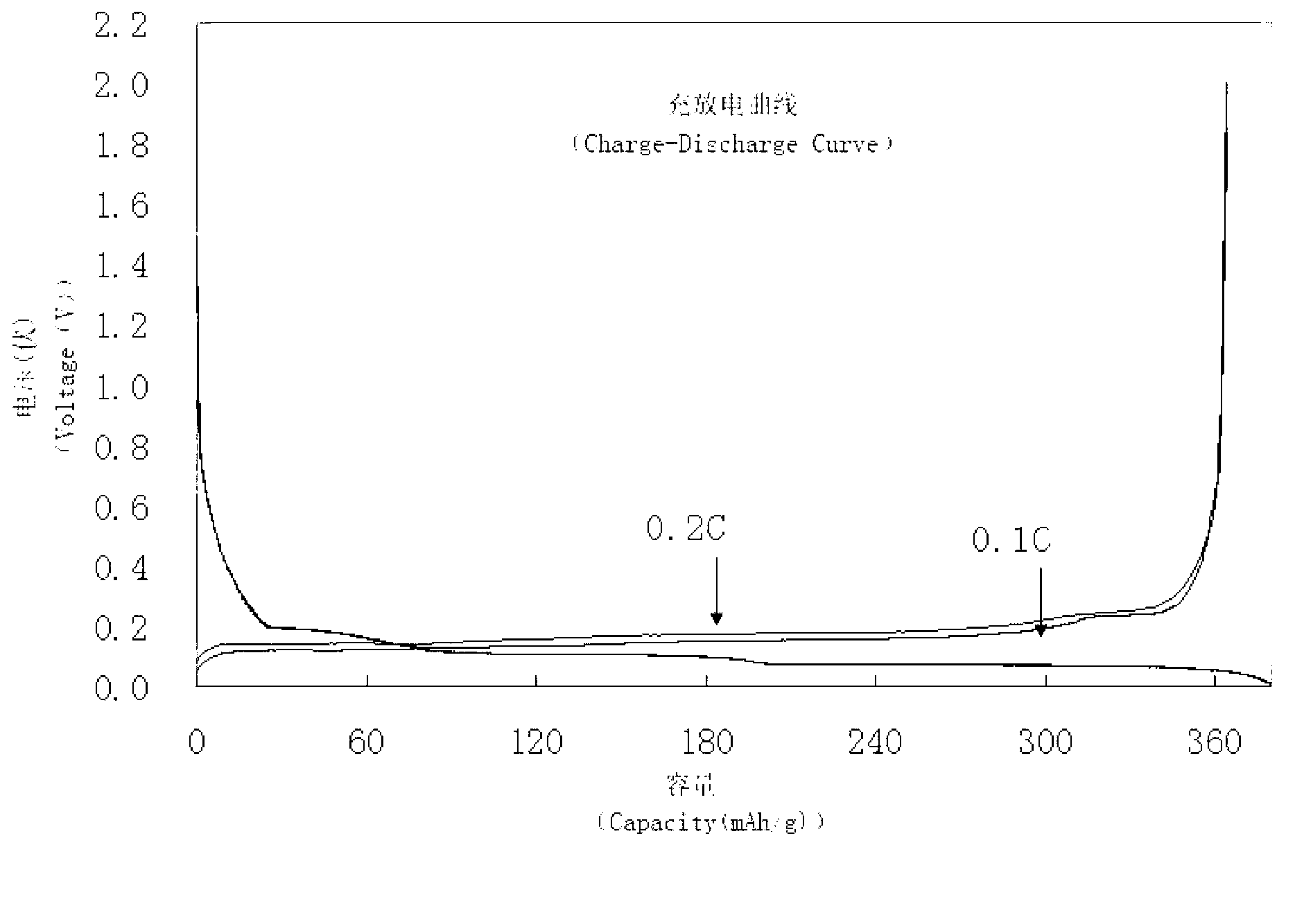

Image

Examples

Embodiment 1

[0027] 1. Prepare the sample to be tested: take 200 grams of natural graphite (Natural Graphite) sample, and conductive agent, binder and thickener, according to natural graphite: conductive agent: binder: thickener: water is 95.2:1.5 The weight ratio of :1.5:1.8:130 is mixed with SDF-400 mixer to prepare a uniform slurry (suspension). According to 0.6g / dm 2 The areal density is uniformly coated on a 9μm double photoelectrolytic copper foil, preferably a rolled copper foil, by a DYG-135 coating machine, and a pole piece about 70μm thick is formed after drying. Press the pole piece at 1.5g / cm 3 After the compaction density is rolled by a Xingtai roller press, a φ11.95mm punch is used to cut the pole piece into the pole piece required for the half-cell. Under the protection of nitrogen or argon, bake in a vacuum oven at 70°C for 12 hours. After removing the moisture in the pole piece, weigh the weight of the pole piece dressing, and calculate its active material content accord...

Embodiment 2

[0034]1. Prepare the sample to be tested: take 200 grams of artificial graphite (Artificial Graphite) sample, and conductive agent, binder and thickener, according to artificial graphite: conductive agent: binder: thickener: water is 94.7:1.8 The weight ratio of :1.0:2.5:130 is stirred and mixed in the SDF-400 mixer to prepare a uniform slurry (suspension). According to 0.8g / dm 2 The areal density is uniformly coated on a 9μm double photoelectrolytic copper foil, preferably a rolled copper foil, by a DYG-135 coating machine, and a pole piece about 85μm thick is formed after drying. Press the pole piece at 1.35g / cm 3 After the compaction density is rolled by a Xingtai roller press, a φ11.95mm punch is used to cut the pole piece into the pole piece required for the half-cell. Under the protection of nitrogen or argon, bake in a vacuum oven at 80°C for 10 hours. After removing all the moisture in the pole piece, weigh the weight of the pole piece dressing, and calculate its act...

Embodiment 3

[0041] 1. Prepare the sample to be tested: take 200 grams of composite graphite (Composite Graphite) sample, and conductive agent, binder and thickener, according to artificial graphite: conductive agent: binder: thickener: water is 95.2:1.8 The weight ratio of :1.5:2.0:130 is stirred and mixed in the SDF-400 mixer to prepare a uniform slurry (suspension). According to 1.0g / dm 2 The areal density is uniformly coated on a 9μm double photoelectrolytic copper foil, preferably a rolled copper foil, by a DYG-135 coating machine, and a pole piece about 100μm thick is formed after drying. Press the pole piece to 1.1g / cm 3 After the compaction density is rolled by a Xingtai roller press, a φ11.95mm punch is used to cut the pole piece into the pole piece required for the half-cell. Under the protection of nitrogen or argon, bake in a vacuum oven at 90°C for 8 hours. After removing all the moisture in the pole piece, weigh the weight of the pole piece dressing, and calculate its activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com