Defect detection method

A defect detection and variance value technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of incorrect detection, inability to accurately reflect the actual morphology of the cell, and reduce the accuracy and efficiency of defect scanning, so as to improve the accuracy efficiency and efficiency, and the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

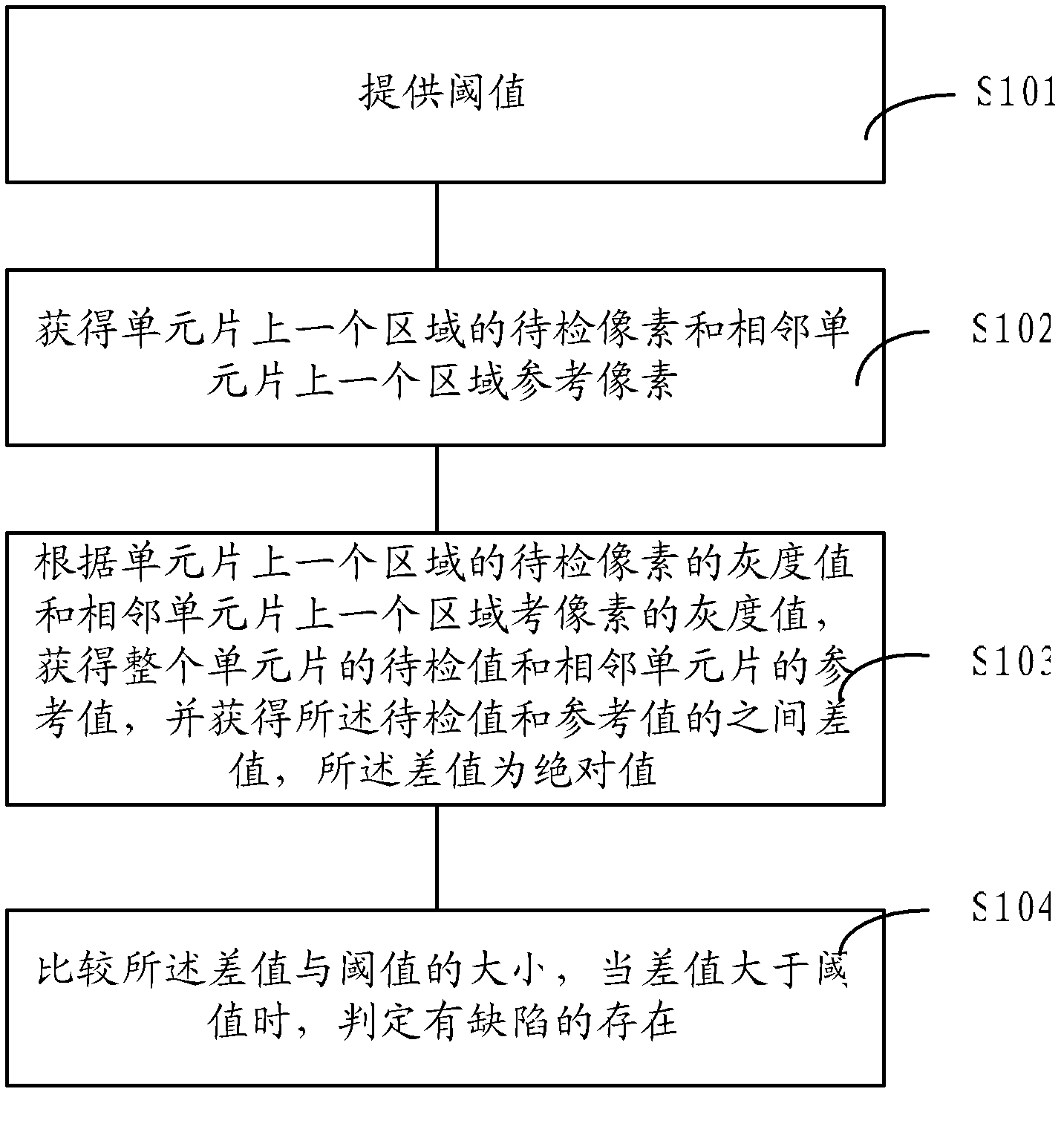

[0034] In the process of detecting defects on the semiconductor substrate, the inventor found that in the prior art, the value to be inspected of a unit chip is obtained according to the gray value of a region on the unit chip, while the difference of the area on the product unit chip is relatively obvious. The detection value cannot accurately reflect the actual morphology of the unit chip, and it is easy to cause incorrect detection of defects during defect scanning, and the efficiency and accuracy of defect detection are low. In order to solve the above problems, the inventor proposed a defect detection method.

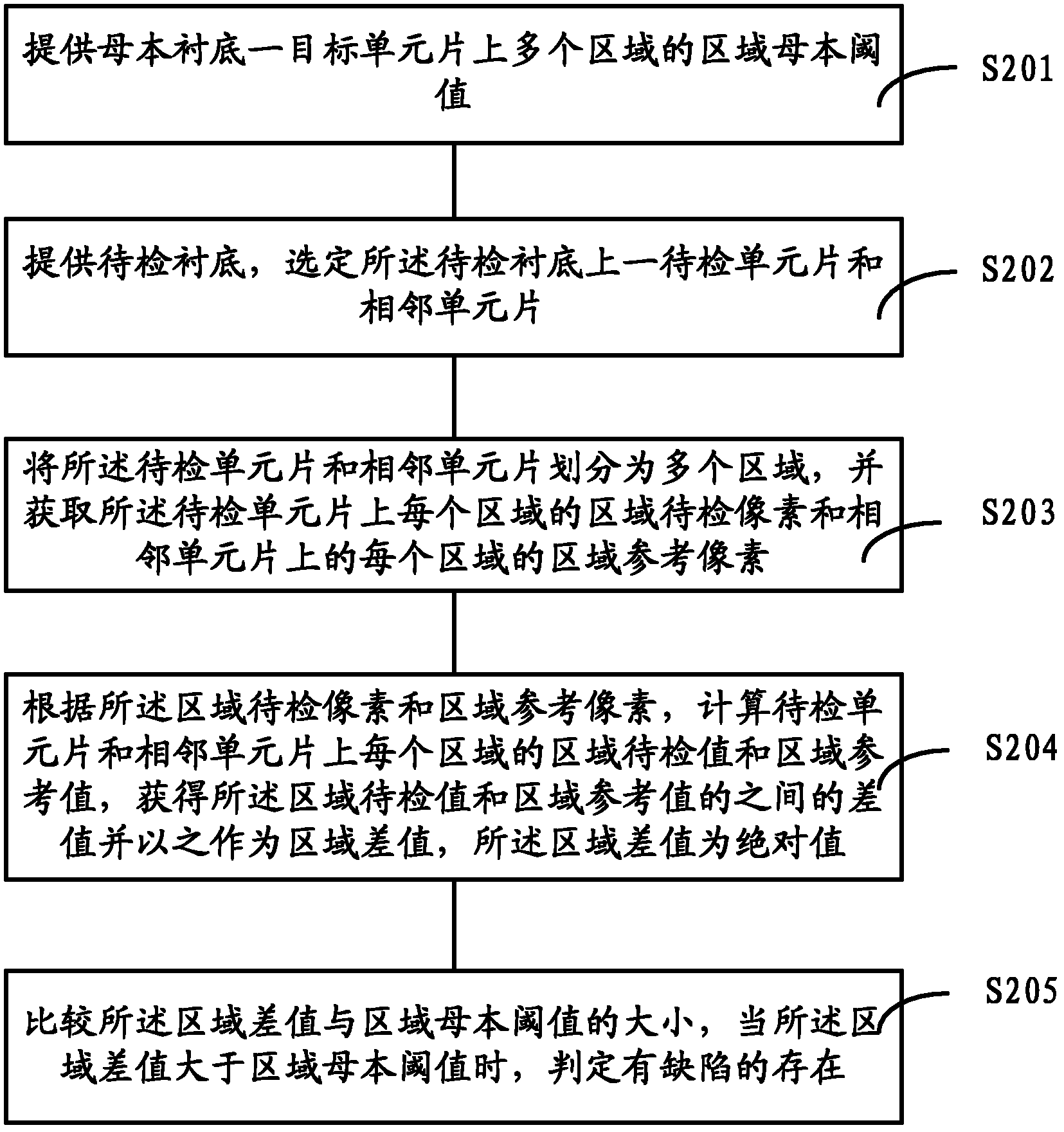

[0035] refer to figure 2 , is a schematic flowchart of an embodiment of the defect detection method of the present invention.

[0036] Step S201, providing regional mother thresholds of multiple regions on the mother substrate-target die;

[0037] Step S202, providing a substrate to be inspected, and selecting a die to be inspected and adjacent dies on the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com