Composite multi-stage pulse tube refrigerator working in 1-2K temperature zone

A pulse tube refrigerator, composite technology, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of expensive, difficult to obtain, and soaring helium-3 prices, and achieve low cost, easy to obtain, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

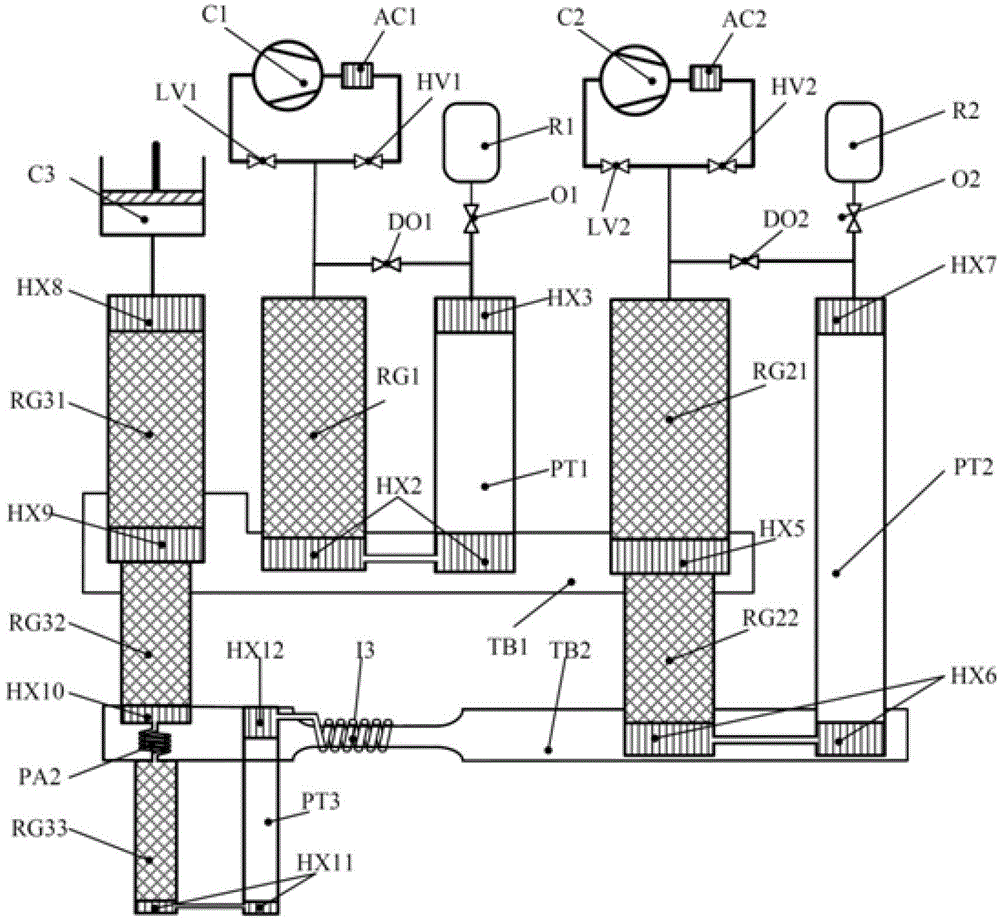

[0027] Such as figure 1 As shown, a composite multi-stage pulse tube refrigerator working at 1-2K includes: a pre-cooling first-stage low-frequency pulse tube refrigerator, a pre-cooling second-stage low-frequency pulse tube refrigerator, a first-stage thermal The bridge TB1, the second-stage heat bridge TB2 and the low-temperature stage high-frequency low-frequency pulse tube refrigerator, the pre-cooling stage first-stage low-frequency pulse tube refrigerator and the pre-cooling stage second-stage low-frequency pulse tube refrigerator form the pre-cooling stage low-frequency pulse tube refrigerator The refrigerator unit provides pre-cooling for the low-temperature high-frequency low-temperature pulse tube refrigerator through the first-stage thermal bridge TB1 and the second-stage thermal bridge TB2.

[0028] Among them, the first-stage low-frequency pulse tube refrigerator in the pre-cooling stage is composed of the first-stage compressor C1, the first-stage aftercooler AC1...

Embodiment 2

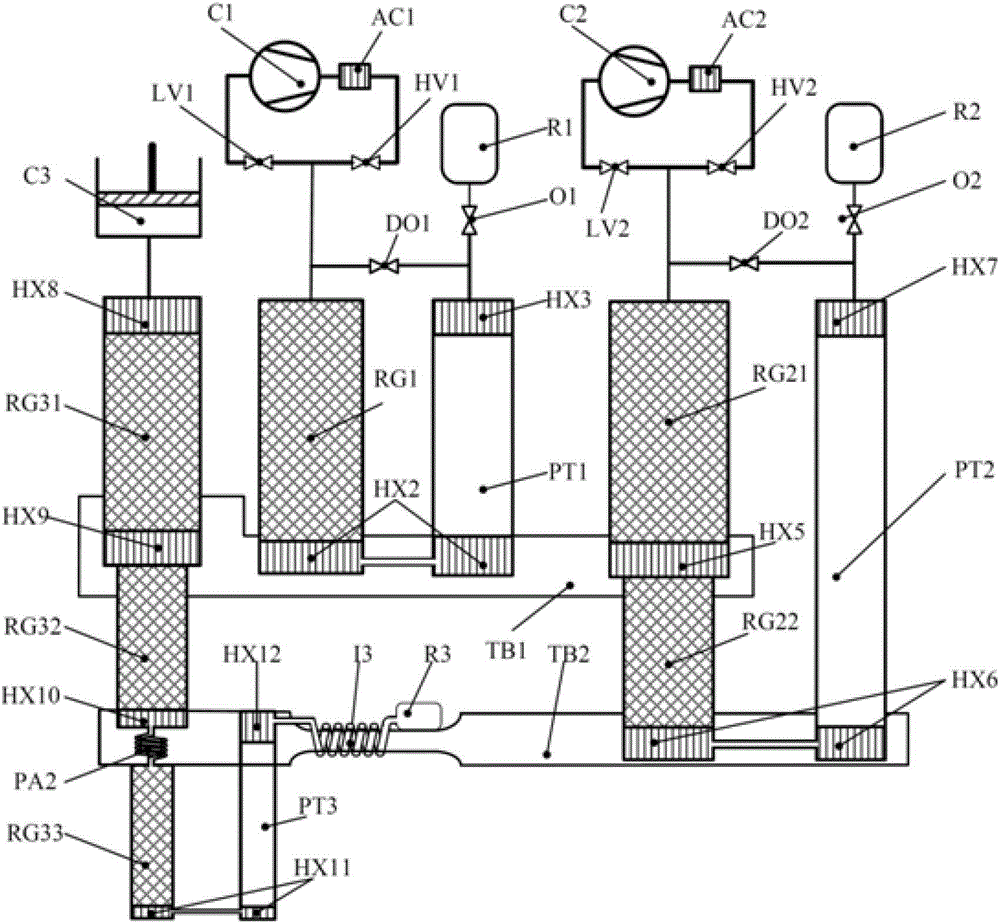

[0040] Such as figure 2As shown, a composite pulse tube refrigerator working at 1-2K differs from Embodiment 1 in that the phase modulation method of the low-temperature grade high-frequency pulse tube refrigerator is a low-temperature grade inertial tube I3 and a low-temperature grade gas storage The combination of R3, and the low-temperature gas storage R3 is arranged on the second thermal bridge TB2. By using the low-temperature gas storage R3, a better phase adjustment angle can be obtained in the low-temperature high-frequency pulse tube refrigerator, and finally further improve The cooling efficiency of low-temperature high-frequency pulse tube refrigerators at 1-2K.

Embodiment 3

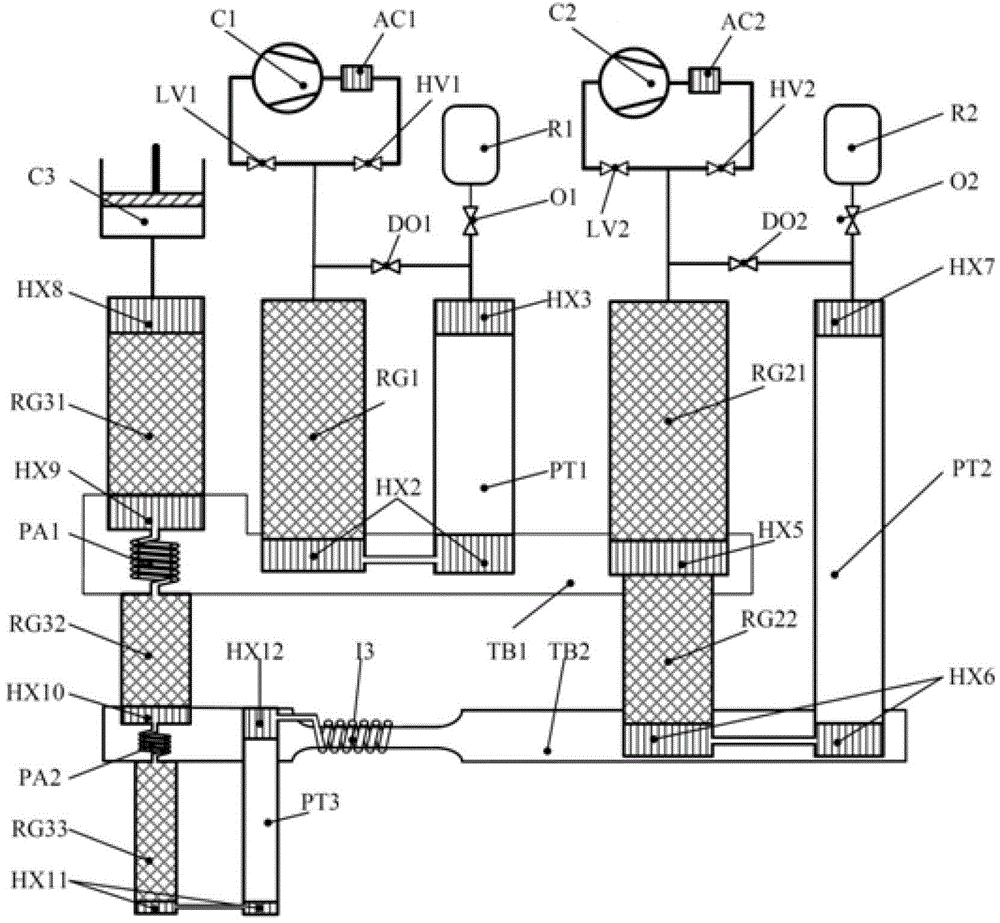

[0042] Such as image 3 As shown, a composite pulse tube refrigerator working at 1-2K differs from Embodiment 1 in that: the first pre-cooling section regenerator of the low-temperature stage and the cold-end heat exchanger HX9 of the low-temperature stage second pre-cooling section A first-stage sound pressure amplifier PA1 is arranged between the regenerators RG32 to amplify the pressure ratio of the cold end of the regenerator in the first pre-cooling section of the low-temperature stage. The first-stage sound pressure amplifier PA1 can make the high-frequency pulse tube of the low-temperature stage The cold end pressure ratio of the refrigerator is further enlarged, so that it has higher efficiency in the 1-2K temperature range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com