Stay cable device for kilometric cable stayed bridge and mounting method thereof

An installation method and cable-stayed technology, which are applied in bridges, bridge parts, bridge construction, etc., can solve the problems of difficult construction of gravity anchors, poor durability of sag effect, and difficult structure of cable-stayed bridges. The effect of optimizing the combined effect, improving the equivalent stiffness, and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

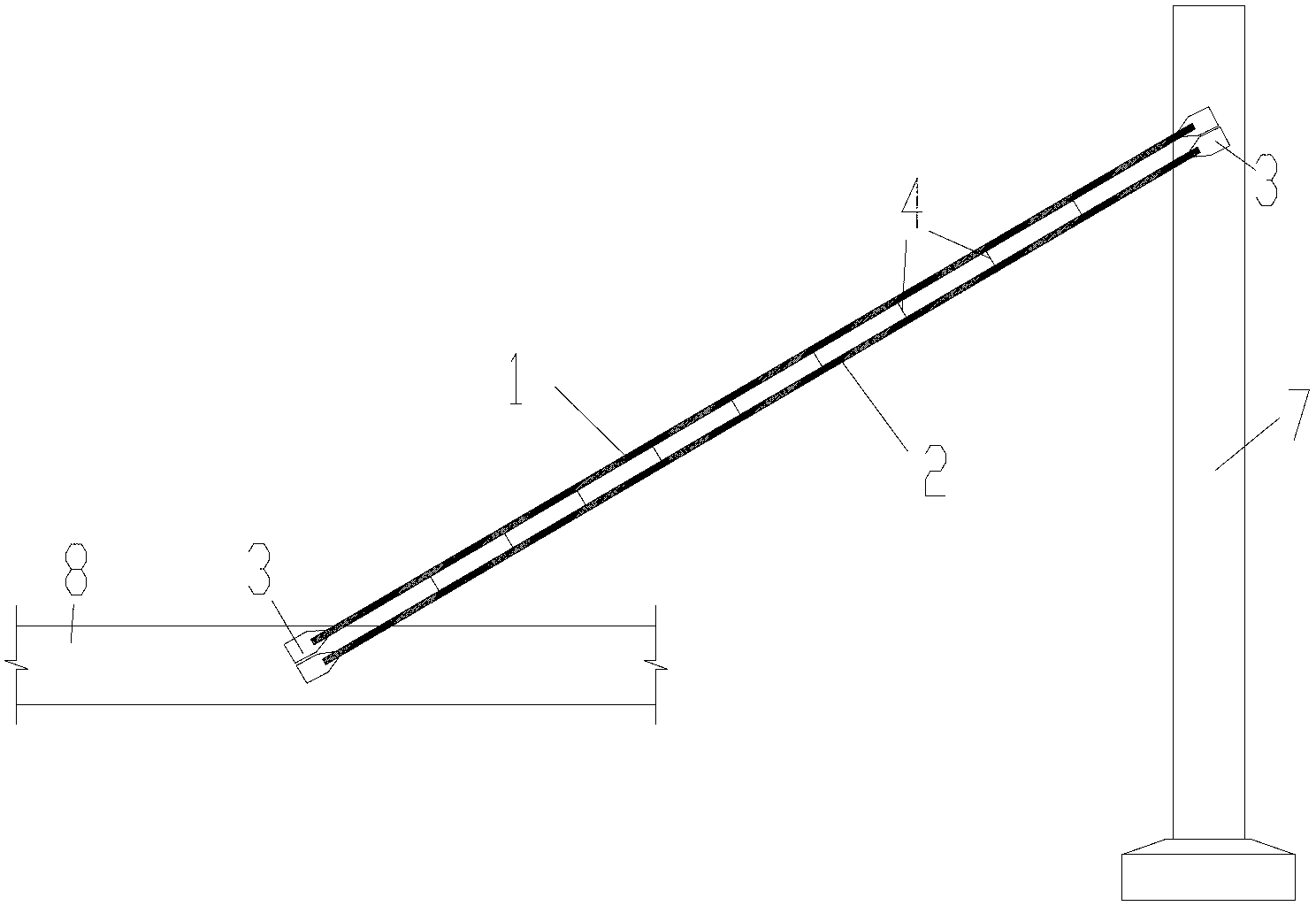

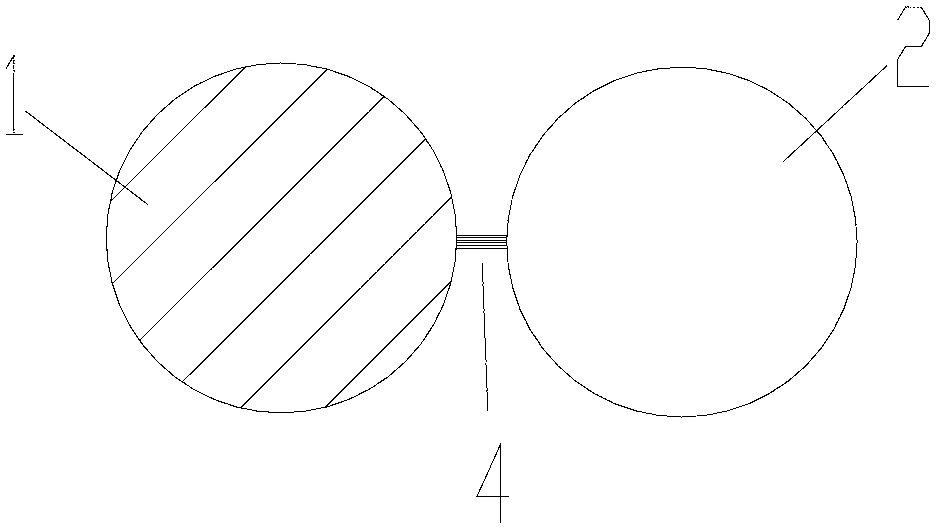

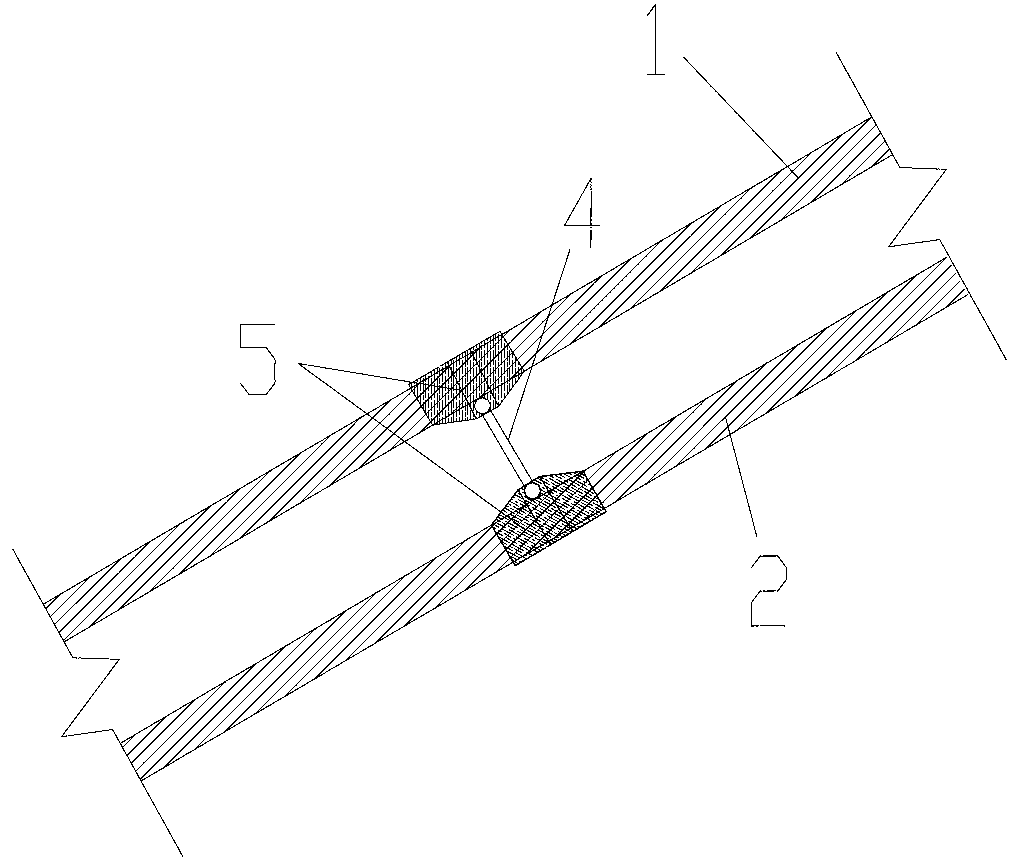

[0036] like Figure 1 to Figure 4As shown, a kind of cable-stayed device for the kilometer-level cable-stayed bridge of the present invention comprises the first cable-stayed cable 1 and the second cable-stayed cable 2 that are positioned at the same cable position, and the first cable-stayed cable 1 is made of steel The second stay cable 2 is made of carbon fiber reinforced composite material, and the two ends of the first stay cable 1 and the second stay cable 2 are respectively fixedly connected to the bridge structure through anchoring devices. The bridge structure mainly includes a main tower 7 and a main girder 8 . The tension end of the first stay cable 1 and the tension end of the second stay cable 2 are fixedly connected to the main tower 7 respectively, and the anchor end of the first stay cable 1 and the anchor end of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com