Integrated bunch type radiant boiler and preheating boiler mixed energy utilization device

A preheating boiler and hybrid technology, applied in the field of integrated beam radiant boiler preheating boiler hybrid energy utilization device, can solve the problems of complex reliability, large space occupation, increased equipment investment, etc., and achieve energy recovery and utilization rate High efficiency, convenient transportation and installation, and improved energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

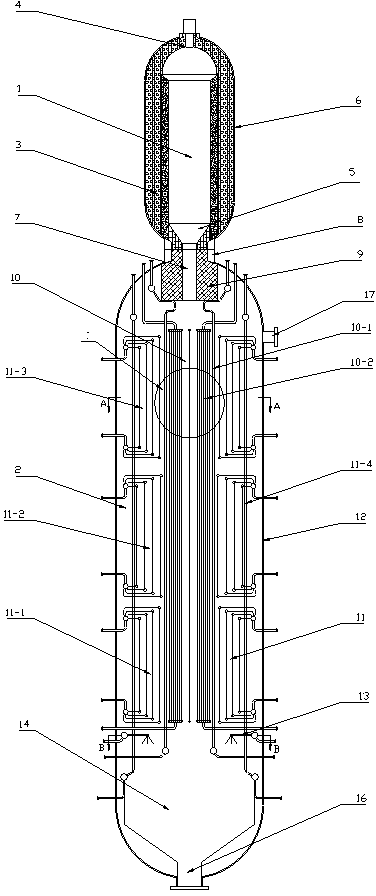

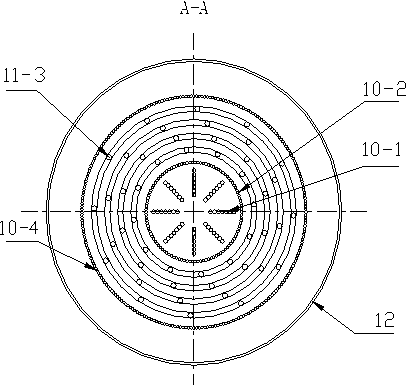

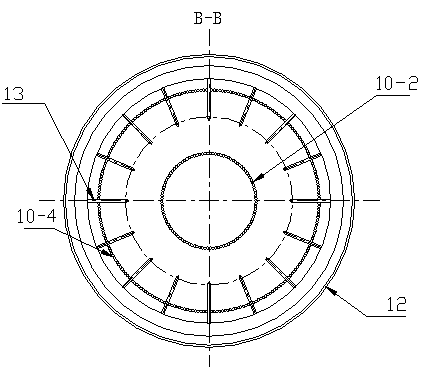

[0033] Such as Figure 1-4 As shown, the integrated beam radiant boiler preheating boiler hybrid energy utilization device includes a gasification furnace body 1 and a heat recovery device 2, the gasification furnace body 1 is located above the heat recovery device 2, and the gasification furnace body It consists of a pressure shell 6, a refractory lining (or water-cooled wall) 3, a slag lower port 5 and a nozzle channel 4. The gasifier is an entrained-flow gasifier, including various types of gasifiers such as single-nozzle and multi-nozzle gasifiers, coal slurry and pulverized coal gasifiers, water-walled and refractory-lined gasifiers ( figure 1 Take the entrained bed gasification furnace body with single nozzle refractory lining structure as an example).

[0034] The heat recovery device 2 is a radiant boiler preheating boiler hybrid heat recovery device, including a synthesis gas inlet 7, a radiation heat exchange component 10, a slag pool 14, a desuperheater component 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com