Alkali-activated high-performance water reducer and preparation method thereof

A compound alkali activator and high-performance technology, applied in the field of preparation of concrete admixtures, can solve problems such as poor workability, affecting concrete strength, and poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

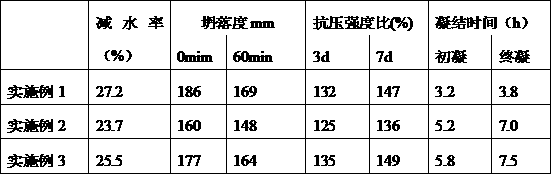

Examples

Embodiment 1

[0022] An alkali-activated high-performance water reducer, the content of the composite alkali activator is 10% by weight, the content of the composite water reducer is 20% by weight, the content of the lignosulfonate is 6% by weight, and the content of the composite retarder is 2% by weight, the content of the composite air-entraining agent is 0.2% by weight, the content of the composite thickener is 0.2% by weight, and the content of the composite regulator is 1.5% by weight, wherein:

[0023] (1) Composition of compound base activator:

[0024] Sodium hydroxide: calcium hydroxide: sodium carbonate: sodium silicate aqueous solution = 3:0.5:2:4.5 (weight ratio);

[0025] (2) Composition of composite retarder:

[0026] Sodium gluconate: sodium hexametaphosphate=7:3 (weight ratio);

[0027] (3) Composition of composite air-entraining agent:

[0028] Triterpene saponins: sodium lauryl sulfate = 9:1 (weight ratio);

[0029] (4) Composition of compound regulator:

[0030] Tri...

Embodiment 2

[0032] An alkali-activated high-performance water reducer, the content of the composite alkali activator is 6% by weight, the content of the composite water reducer is 15% by weight, the content of the lignosulfonate is 8% by weight, and the content of the composite retarder is 4% by weight, the content of the composite air-entraining agent is 0.5% by weight, the content of the composite thickener is 0.5% by weight, and the content of the composite regulator is 2.5% by weight, wherein:

[0033] (1) Composition of compound base activator:

[0034] Sodium hydroxide: lithium hydroxide: sodium carbonate: sodium silicate aqueous solution = 2:1:3:4 (weight ratio);

[0035] (2) Composition of composite retarder:

[0036] Sodium gluconate: sucrose: borax, sodium tripolyphosphate = 4:2:1:3 (weight ratio);

[0037] (3) Composition of air-entraining agent:

[0038] Triterpene saponins: sodium α-olefin sulfonate = 7:3 (weight ratio);

[0039] (4) Composition of compound regulator:

...

Embodiment 3

[0042] An alkali-activated high-performance water reducer, the content of the composite alkali activator is 8% by weight, the content of the composite water reducer is 18% by weight, the content of the lignosulfonate is 4% by weight, and the content of the composite retarder is 5% by weight, the content of the composite air-entraining agent is 0.3% by weight, the content of the composite thickener is 0.3% by weight, and the content of the composite regulator is 3% by weight, wherein:

[0043] (1) Composition of compound base activator:

[0044] Sodium hydroxide: sodium carbonate: sodium silicate aqueous solution = 3:2:5 (weight ratio);

[0045] (2) Composition of composite retarder:

[0046] Sodium gluconate: sodium citrate: borax, sodium pyrophosphate = 5:2:1:2 (weight ratio);

[0047] (3) Composition of composite air-entraining agent:

[0048] Triterpene saponins: sodium α-olefin sulfonate = 8:2 (weight ratio);

[0049] (4) Composition of compound regulator:

[0050] Tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com