Method for preparing high-specific-surface-area porous graphitic nanocarbon plate with coconut shells serving as raw materials

A high specific surface area, porous graphite technology, applied in nanotechnology, nanocarbon, chemical instruments and methods for materials and surface science, etc. It is beneficial to the transmission of electrons, the equipment required for the reaction is simple, and the production safety is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

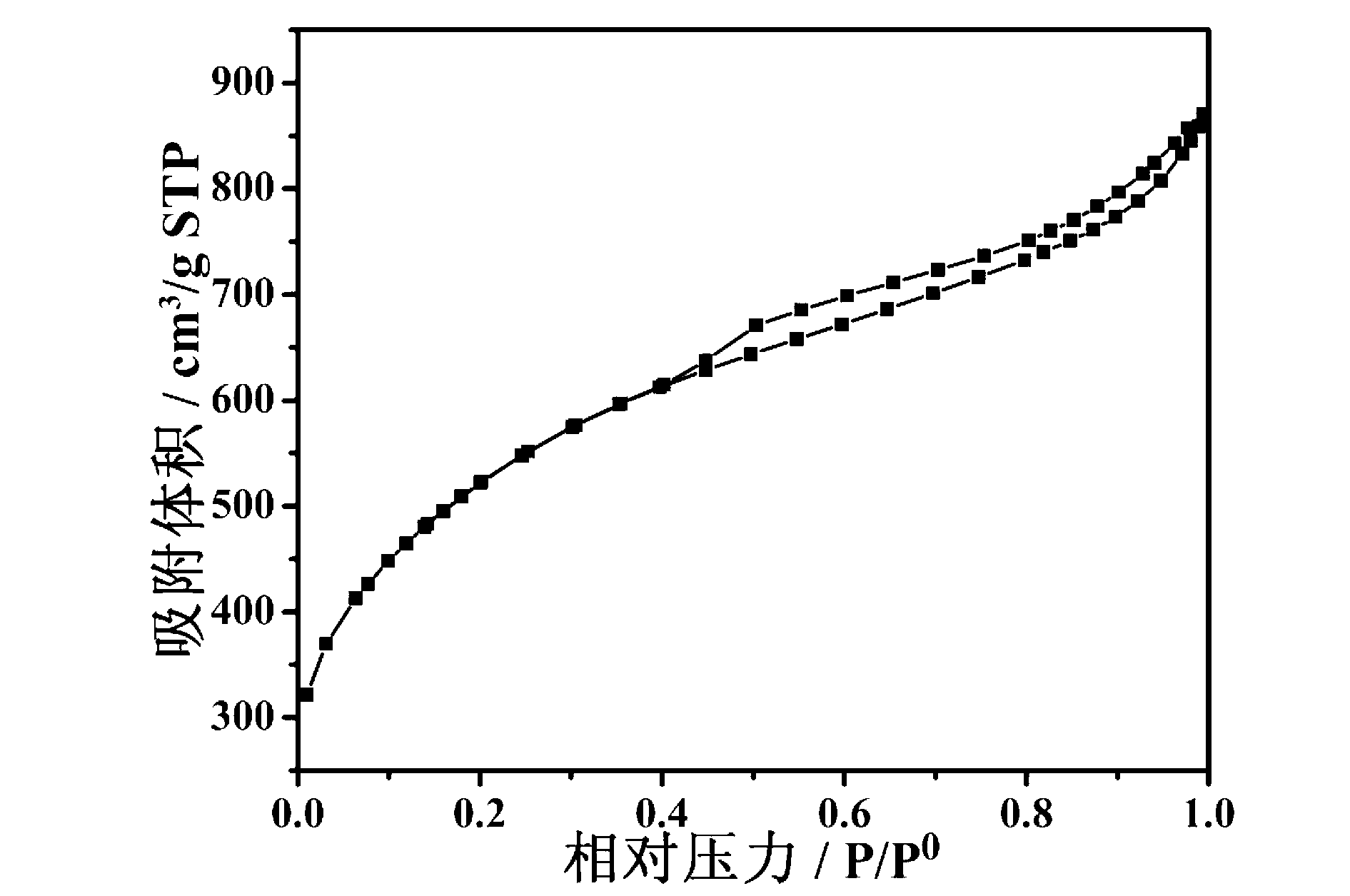

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: present embodiment is a kind of method for raw material preparation high specific surface area porous graphitized nano-carbon sheet with coconut shell, specifically operates according to the following steps: one, adopt acid treatment method or alkali treatment method to coconut shell Carry out pretreatment; 2. Add catalyst, activator and the coconut shell pretreated in step 1 to the solvent, and stir for 6~8h at a temperature of 50~80°C and a stirring speed of 100~350r / min to obtain a complex; Wherein, the mass ratio of coconut shell and catalyst is 1~5:1, and the mass ratio of coconut shell and activator is 1~5:1; Three, under the condition that temperature is 50 ℃~200 ℃, the The complex is solidified for 6~8h to obtain the product; 4. The temperature is raised to 700℃~1100℃ at a rate of 1~15℃ / min, and then the product of step 3 is heat-treated at 700℃~1100℃ for 10min~5h to obtain product; wherein the flow rate of the heat treatment atmosphere ...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the acid treatment method described in step 1 carries out the concrete operation steps of pretreatment to coconut shell as follows: add coconut shell to mass concentration and be 10%~15 % nitric acid solution, reflux at 70~150°C for 4~8h to complete the acid treatment, wherein the mass volume ratio of coconut shell to nitric acid solution is 5g:50mL. Others are different from the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the alkali treatment method described in step 1 carries out the specific operation steps of pretreatment to coconut shell as follows: adding coconut shell to mass concentration is 10%~ Ultrasonic stirring in 20% KOH solution for 3~7h, then hydrothermal reaction at 100°C~200°C for 2~5h, washing with distilled water until the pH of the lotion is 7.0, and drying at 80°C~100°C for 6~ 8h, the alkali treatment is completed, wherein the mass volume ratio of coconut shell and KOH solution is 5g:50mL. Others are different from the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com