Tray separation device

A pallet separation and unification technology, applied in the direction of transportation and packaging, object destacking, etc., can solve the problems of large vibration, instability, lowering, etc., achieve the effect of stable separation operation, high separation efficiency, and reduce hard friction problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

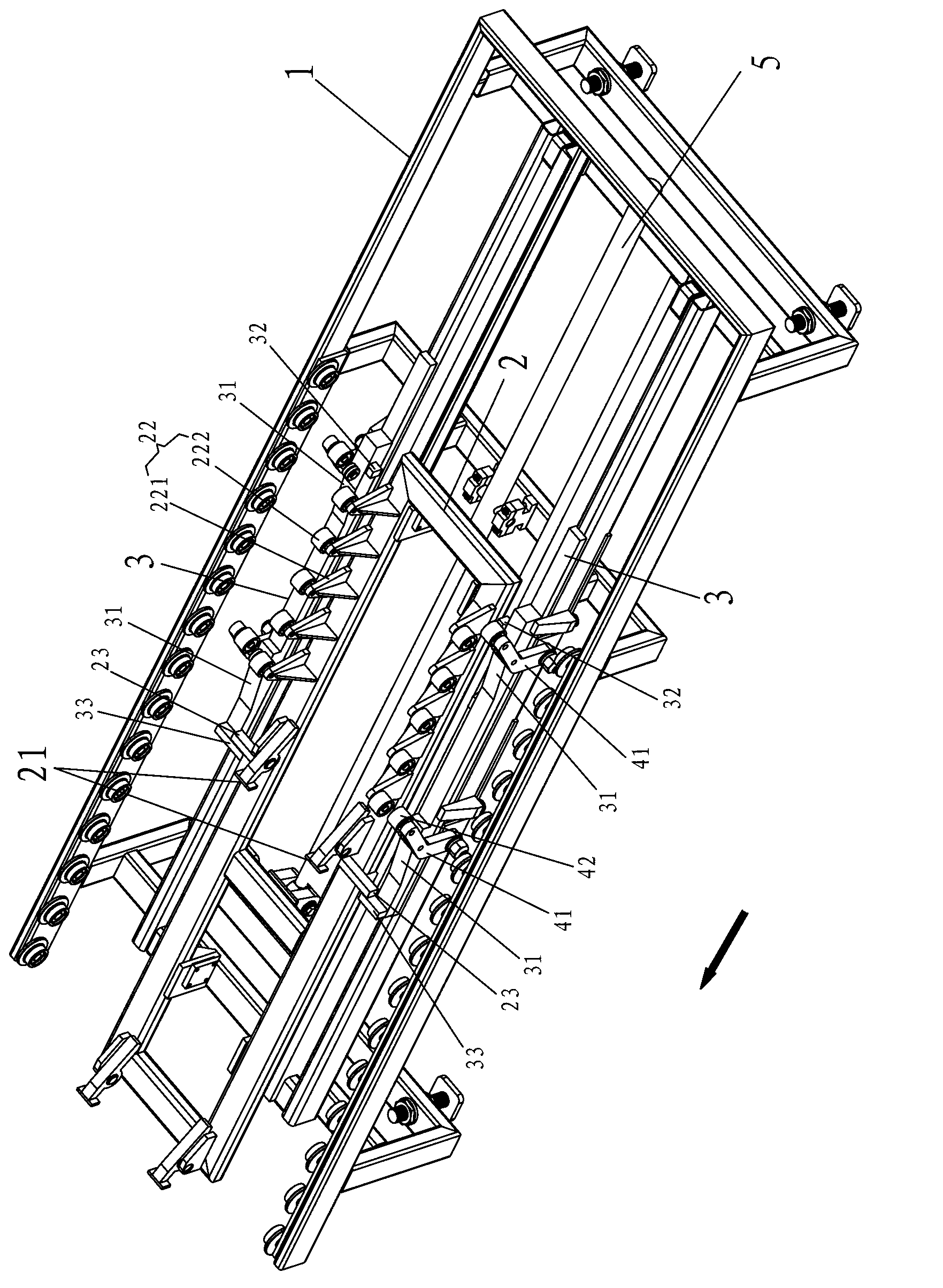

[0041] Such as Figure 1-2 Shown is a kind of tray separation device related to the present invention, including a base 1 and a movable frame 2, two adjustment rails 3, a second support part 4 and an oil cylinder 5 arranged on the base 1; the tray 6 is carried out on the base 1 For separation, the direction in which the tray 6 is pushed out (the direction of the arrow in the figure) is the direction from back to front.

[0042] The movable frame 2 is placed on the base 1, and is driven by the oil cylinder 5 to move back and forth. The upper surface of the movable frame 2 protrudes forward and backward and is provided with a push plate part 21 and a first support part 22. The following is based on the preset stacked trays 6 to be separated, and the height of the push plate part 21 is between the penultimate blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com