Processing technology of high-performance plate type solar photovoltaic module

A technology of solar photovoltaic and processing technology, applied in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., can solve the problem that the output cycle of equipment and equipment is difficult to achieve the ideal target, and achieve reduced risk of hidden cracks, excellent performance, and processing efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

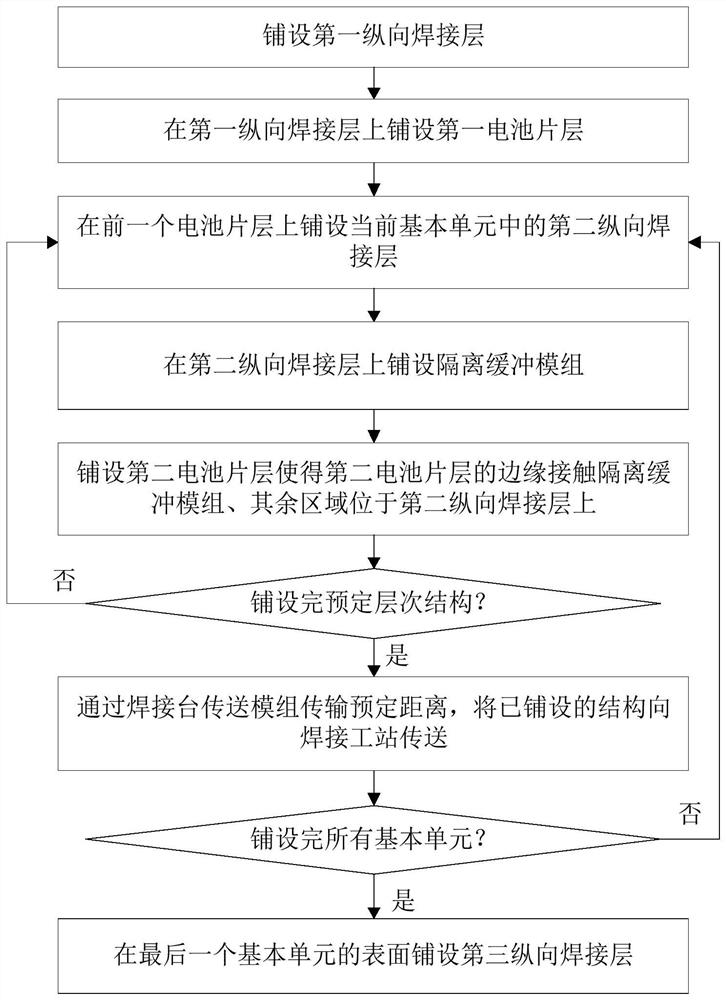

[0035] This application discloses a high-performance plate solar photovoltaic module processing technology, please refer to figure 1 Shown in the flowchart, the processing technology includes the following steps:

[0036] In the laying station, the first longitudinal welding layer 2, the first cell sheet layer 3, several basic units and the third longitudinal welding layer 4 are sequentially laid on the welding station transfer module 1 to form a module to be welded.

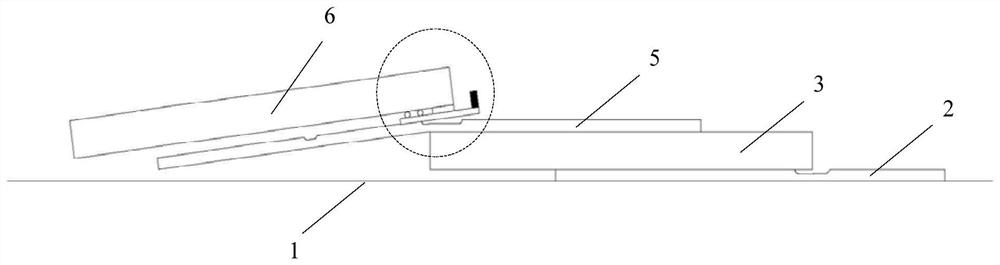

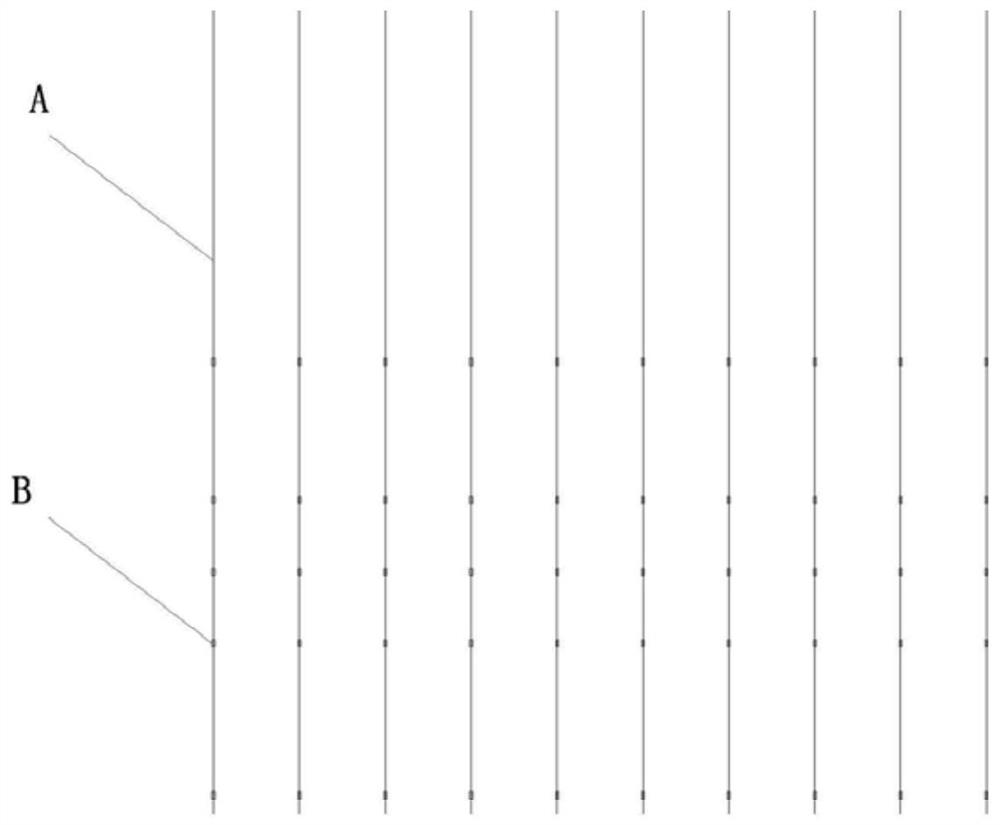

[0037] Please refer to figure 2 , the first longitudinal welding layer 2 is directly laid on the welding station transfer module 1, the back of the first battery sheet layer 3 is laid on the first welding layer 2, and then the first basic unit is laid on the first battery sheet layer 3. Please refer to image 3 In the present application, each longitudinal welding layer in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com