Production method of continuous glass fabric reinforced thermoplastic sheet

A technology for strengthening thermoplastics and thermoplastics, applied in the field of materials, can solve the problems of ignorance, unsatisfactory, and insufficient production of high-strength plastic products, and achieve the effects of reasonable production methods, good quality of finished products, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

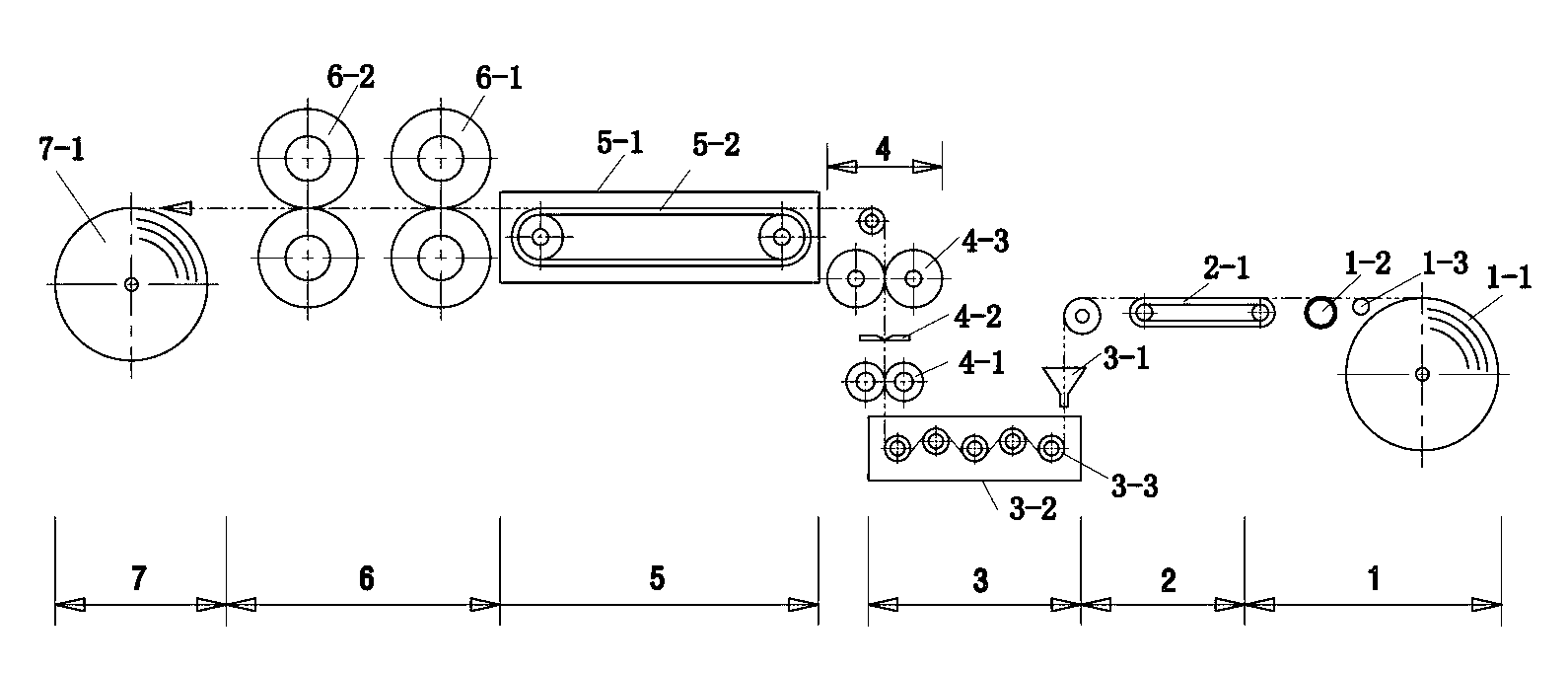

[0031] Hereinafter, the present invention will be further explained through the description of specific embodiments in conjunction with the accompanying drawings.

[0032] A typical specific implementation, please refer to the attached figure 1 with 2 .

[0033] A method for producing a continuous glass fiber cloth reinforced thermoplastic plastic sheet, using thermoplastics as a base material and a roll of continuous glass fiber cloth 1-1 as a starting material, and the production method of the sheet is carried out in the following steps:

[0034] a. Unwinding; in the unwinding process, the electronic tension controller 1-3 controls the traction tension of the glass fiber cloth to be within the range of 80-100NM, and the olive roller 1-2 corrects the deviation to achieve centering;

[0035] b. Flattening; the flattening is to introduce the unwinding fiberglass cloth 1-1 into the flattening device, and spread it flat on the belt conveyor platform 2-1 to make the diameter and weft lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com