All-metal screw pump stator machining equipment

A technology for processing equipment and pump stators, applied in metal processing equipment, metal processing mechanical parts, milling machine equipment, etc., can solve the problems of ineffective discharge of metal chips, knife cutting and blade chipping, and scratches of metal chips in inner holes. Achieve the effect of improving the cutting quality, reducing the amount of cutting tools and increasing the cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

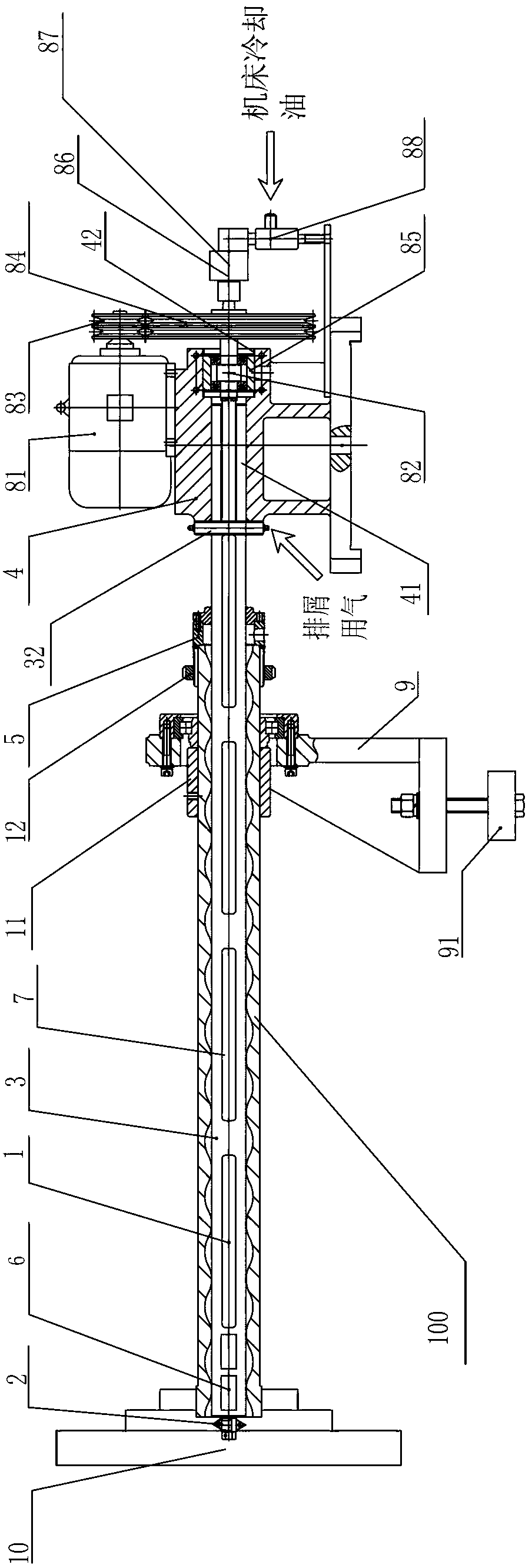

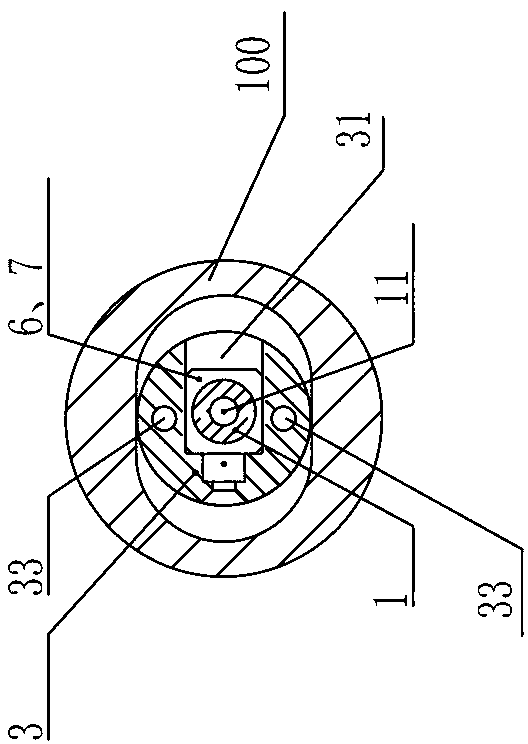

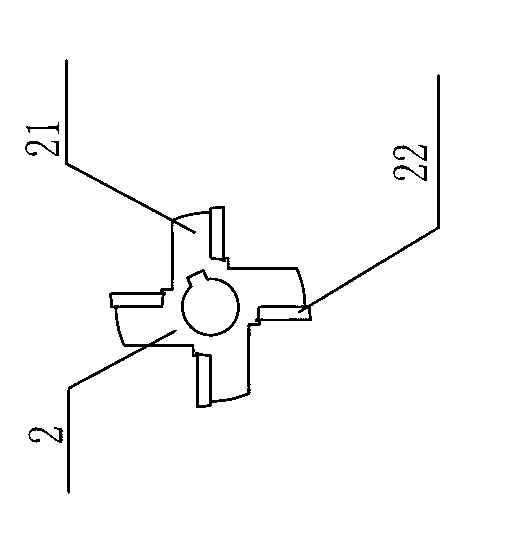

[0017] Embodiment 1: As shown in the figure, a processing equipment for an all-metal screw pump stator includes a cutter bar 1, a cutter head 2, a guide rod 3, a support seat 4, a workpiece fixing device and a tool bar rotation drive device, and a support seat 4 It is fixedly connected with the machine tool (not shown in the figure), the guide rod 3 is provided with a guide sleeve 5, the guide rod 3 is provided with a guide groove 31, the support base 4 is provided with a through hole 41, and the guide rod 3 is provided with a fixed plate 32, guiding The rod 3 is inserted into the through hole 41, the fixed disk 32 is fixedly connected with the front end face of the support seat 4, the knife bar 1 is arranged in the guide groove 31 through the adjustable bushings 6, 7, the cutter head 2 is arranged at the front end of the knife bar 1, and the knife The disk 2 is star-shaped and provided with four blade fixing leaves 21, and the blade fixing blades 21 are provided with forming b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com