Rice product self-rising flour, producing method thereof and application thereof

A technology for rice products and self-raising flour, applied in the fields of application, food preparation, food science, etc., can solve the problems of poor flavor, single-flavored rice cake, and not soft enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

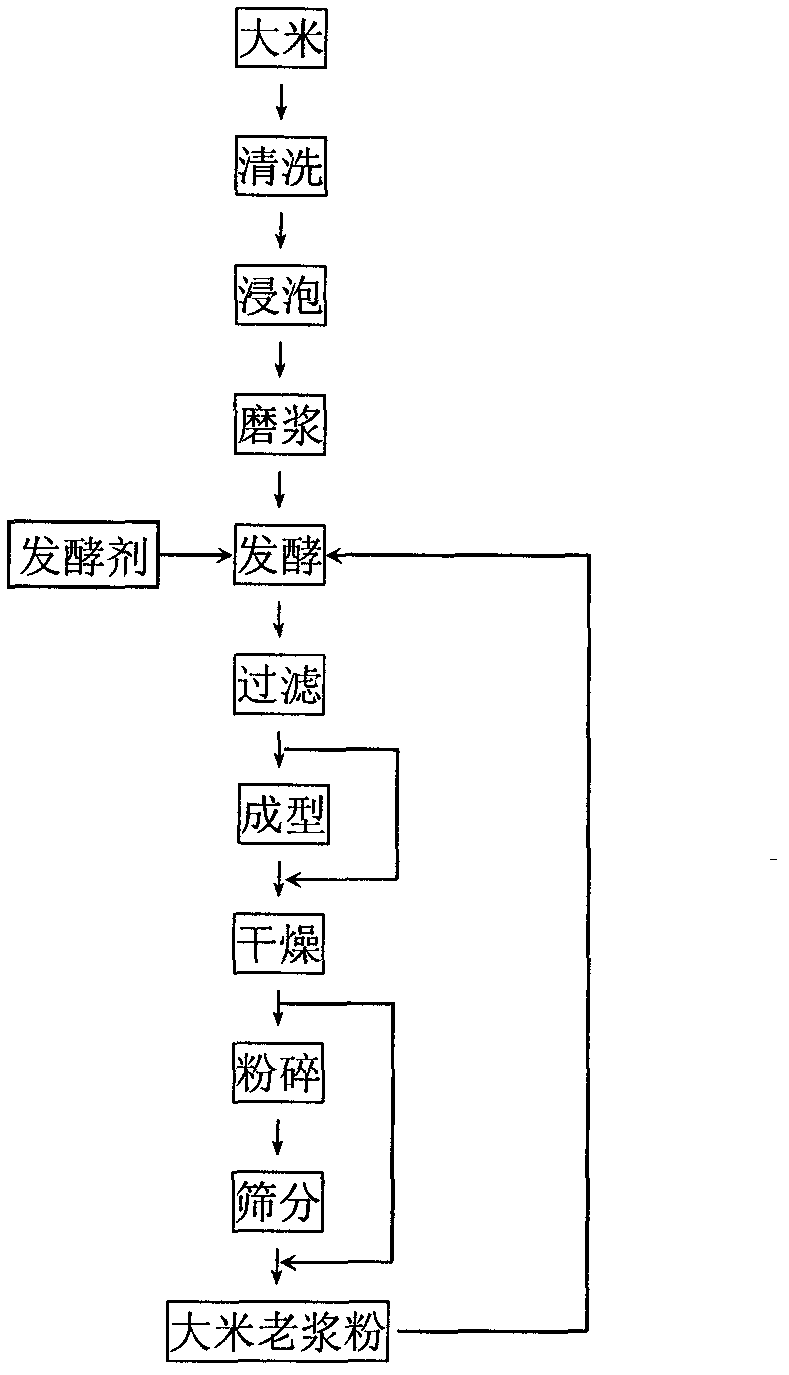

[0121] (1) Utilize the old pulp of the traditional rice cake making process to make old rice starch powder and the application of the old rice powder

[0122] (1) Wash 100 kilograms of rice with water, add 200 kilograms of water to soak for 6 hours, and then refine the pulp to obtain rice milk; Contains the original fermented strains, similar to the old noodle steamed buns, the old jelly was purchased from the rice cake workshop in the vegetable market of Huazhong Agricultural University), stirred and mixed, and fermented at 35°C for 3 hours, so that the volume of the slurry expanded to 1.5 times the original volume, Obtain fermented rice milk, i.e. old rice milk;

[0123] (2) The old rice pulp is passed through a 250-mesh sieve, and the filter residue is taken. The water content of the filter residue is 76%, which is material 1;

[0124] (3) Material 1 is made into molding particles with a particle size of about 0.5mm by a molding machine to obtain material 2;

[0125] (4) ...

Embodiment 2

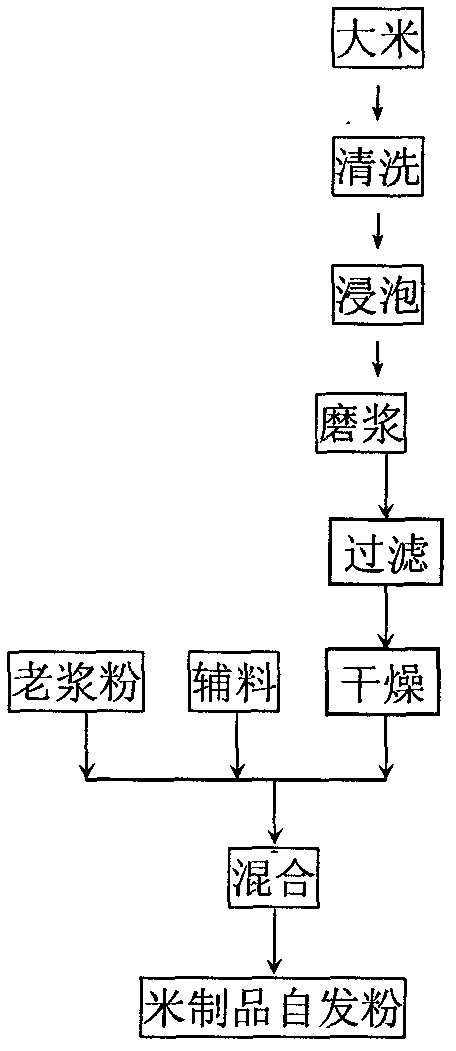

[0149] The technical process of this embodiment is mainly cleaning-soaking-refining-sieving-filtering-drying-batching-mixing-packaging.

[0150] The proportions of the ingredients in parts by weight are as follows:

[0151] A. Main ingredient powder 100 kg;

[0152] B. 20 kg of old rice flour;

[0153] C, 0.8 kg of microbial inoculum; the inoculum is Brettanomyces castellus ZSM-001, the preservation number is CCTCCNO: M207150 (patent application number 2007100536112, patent publication number is CN101173223);

[0154] D. Accessories

[0155] 20 kg of white sugar;

[0156] (1) Refer to Example 1 for the process steps of making old rice pulp with microbial bacterial agents.

[0157] (2) The process steps of making main ingredient powder (using rice as raw material) refer to Example 1.

[0158] The raw material of the main ingredient powder of step (2) is except rice, also can adopt red rice or black rice or corn or millet etc. The rice should be 70 kg, and the rest of the ...

Embodiment 3

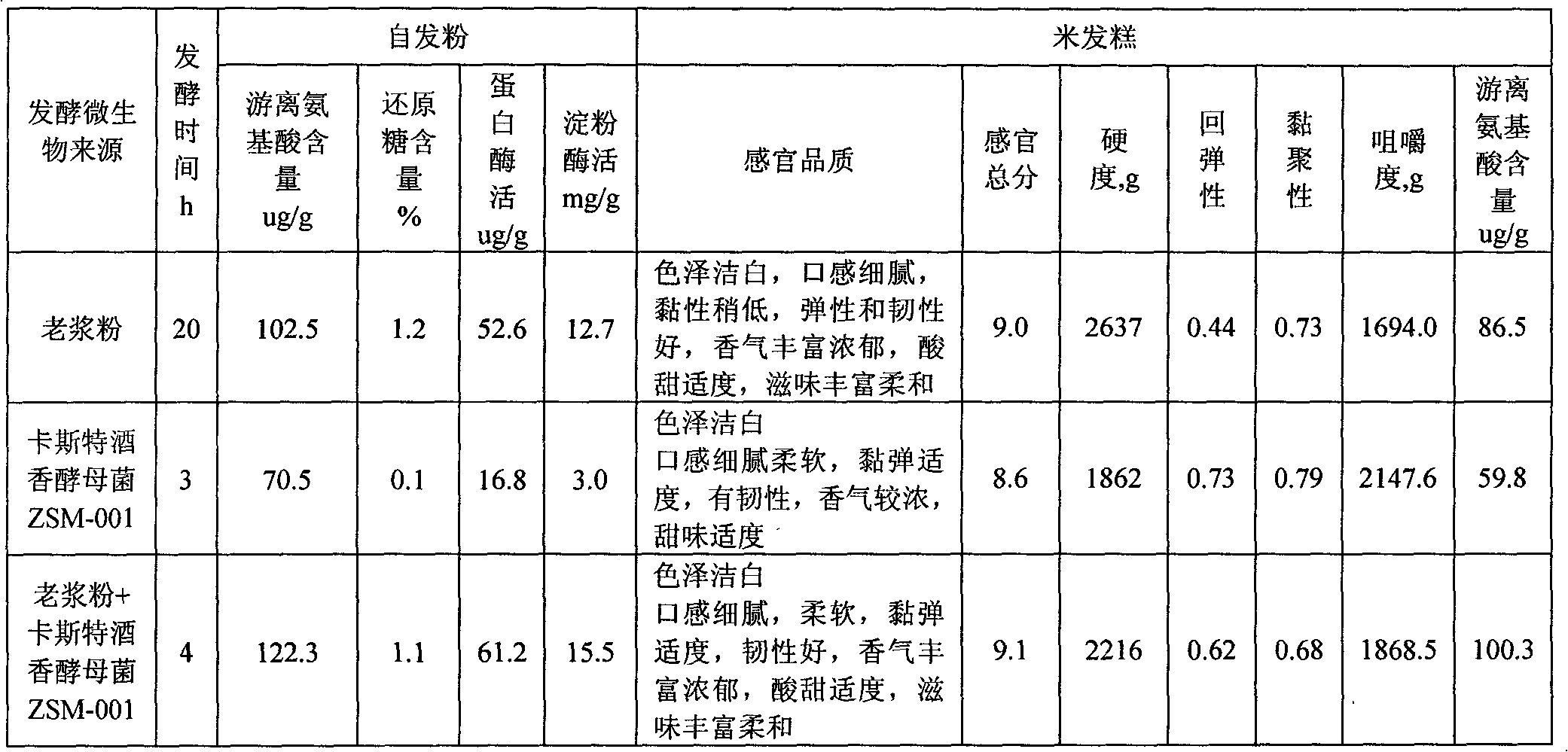

[0164] Embodiment 3: make the old paste powder and the comparison of application effect with different drying methods

[0165] The application of making old rice paste powder, self-raising flour and rice cake with the method of embodiment 2. The drying methods of old rice starch powder are hot air drying (55°C, relative humidity 40%, 8h), microwave drying (microwave dose 0.5w / g, time 30min), freeze drying (pre-freezing at -40°C for 1h, and then freezing Dry in a dryer at about 20°C and 10Pa for 12h).

[0166] Add 100 kg of self-rising flour prepared above to 90 kg of tap water, stir and mix evenly, ferment at 37°C for 3 hours, pour it into a mold, and steam at 100°C for 20 minutes to obtain a rice cake.

[0167] See Table 2 for the quality of old pulp powder made by the above drying method, and Table 3 for the quality of rice cake. From Table 2 and Table 3, it can be seen that the quality of old rice cake made by different drying methods is quite different. The old starch p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com