Cereal instant tea and production method thereof

A technology of instant tea and grains, applied in the field of food processing, which can solve the problems of reduced nutritional content, high production costs, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

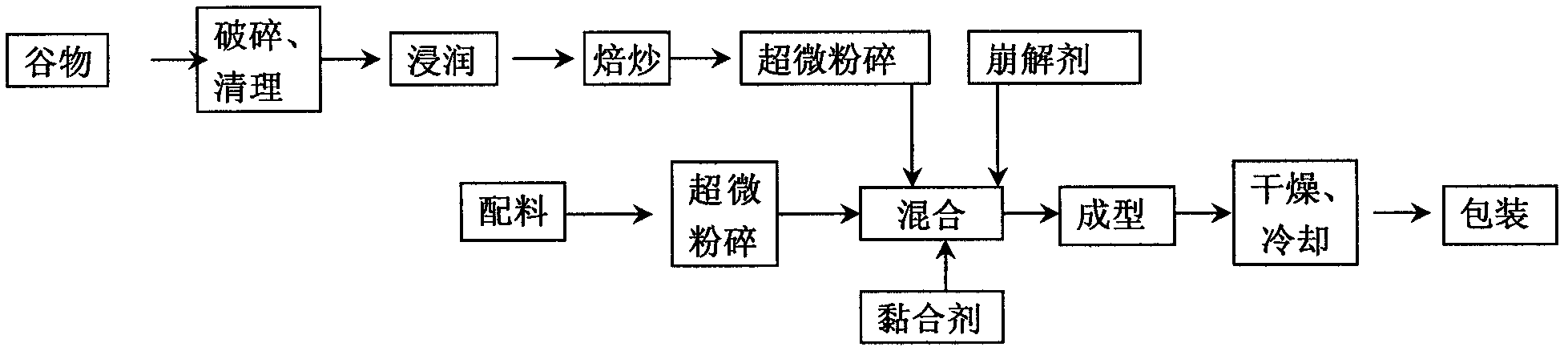

Method used

Image

Examples

Embodiment 1

[0092] Embodiment 1 production process example

[0093] Step 1: Take 130 kilograms of cleaned rice (commercially available), crush it, take the material that has passed through 20 meshes and not passed through 80 mesh sieves, the particle size is 0.18-0.85mm, and about 100 kilograms of rice flour particles are obtained, and set aside;

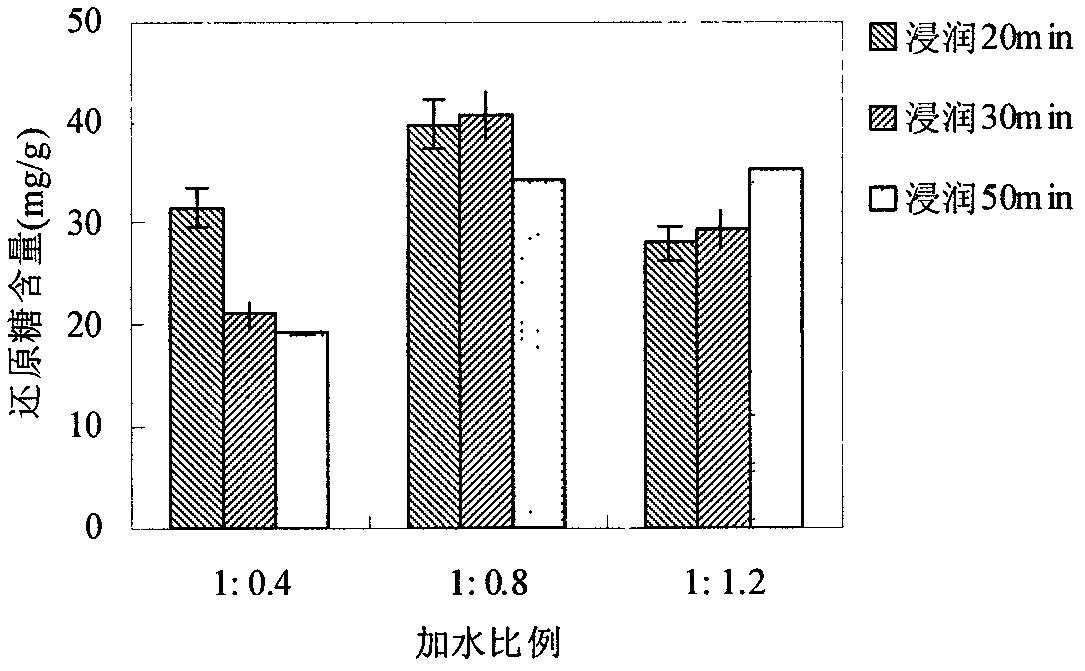

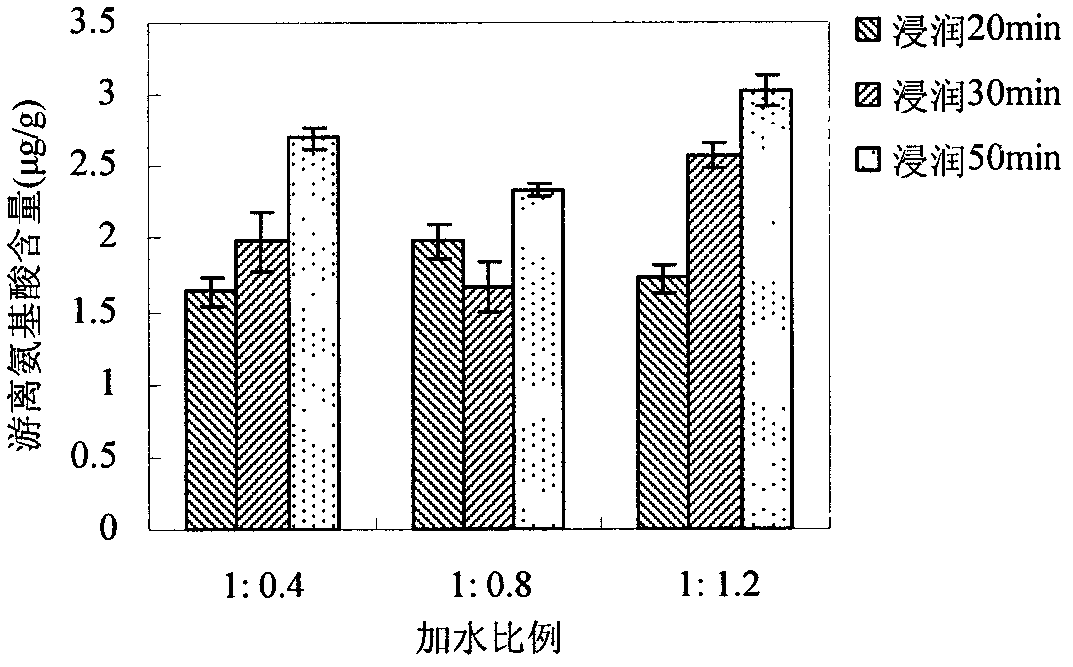

[0094] Step 2: Add 9 kg of water to the above rice flour granules, soak at room temperature (30° C.) for 60 minutes to allow the material to absorb part of the water, and obtain material 1 with a water content of 21.1% (wet basis).

[0095] Step 3: The material obtained in step 2 was roasted at 120°C for 50 minutes to obtain material 2.

[0096] Step 4: Superfinely pulverize the roasted material with a superfine pulverizer (purchased from Beijing Kaikai Duobang Technology Co., Ltd.; model: ZM-50), the average particle size of the pulverized material is 35 μm, and the material is obtained 3.

[0097] Step 5: Weigh 0.3 kg of dried seedless juju...

Embodiment 2

[0109] Embodiment 2: The molding mode of cereal instant tea is an example

[0110] According to the preparation steps of Example 1. In this embodiment, only the molding step 8, that is, the molding method test of the product, is changed. The three molding methods are exemplified as follows:

[0111] (1) Using a granulator (purchased from Taizhou Bojing Pharmaceutical Machinery Co., Ltd., Jiangsu Province, model: Y6-60) to process and shape the material 3 into granules (particle size: 0.5 mm).

[0112] (2) Use a spray granulation fluidized bed dryer (purchased from Hangzhou Qianjiang Drying Equipment Co., Ltd., Zhejiang Province, model: GLZ) to granulate, control the wind speed to 4m / s, transport concentration to 1.5, and temperature to 45°C. The agent flow rate is 0.0012kg / kg material, and the spray pressure is 1.5MPa (particle size is 0.3mm).

[0113] (3) Use a single-punch tablet press (purchased from Guangzhou Kangnuo Pharmaceutical Machinery Co., Ltd., Guangdong Province...

Embodiment 3

[0115] Embodiment 3: Example of the drying method of cereal instant tea

[0116] According to the preparation steps of Example 1. In this embodiment, only step 9 is changed, that is, the drying and cooling method test of the formed material. The three drying and cooling methods are as follows:

[0117] (1) Dry the molded material with hot air in a hot air drying test box at 45°C, with a relative humidity of 35%, and a wind speed of 1m / s (purchased from Dongguan Enterprise Industrial Equipment Manufacturing Factory, Guangdong Province) for 45 minutes, and then cool to room temperature , so that the water content is 12.2% (wet basis).

[0118] (2) After forming the material, at 1.2kW·kg -1 Microwave drying in microwave chemical raw material drying equipment (purchased from Guangzhou Wenbo Industrial Co., Ltd.) took 38 minutes to dry, and cooled to room temperature to make the water content 11.42% (wet basis).

[0119] (3) Dry the formed material with a spray granulation fluid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com