Method manufacturing micro-chamber plate for analysis and micro-chamber plate with samples, micro-chamber plate for analysis and apparatus set manufacturing micro-chamber plate with samples

A manufacturing method and technology of a manufacturing device, which are applied in the field of micro-chamber plates, can solve the problems of surface tension and centrifugal force obstruction, residual small bubble shape, and inability to obtain buoyancy, so as to reduce manufacturing costs, improve accuracy, and shorten analysis requirements. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1 relates to the method for manufacturing a microcavity plate for analysis provided by the present invention.

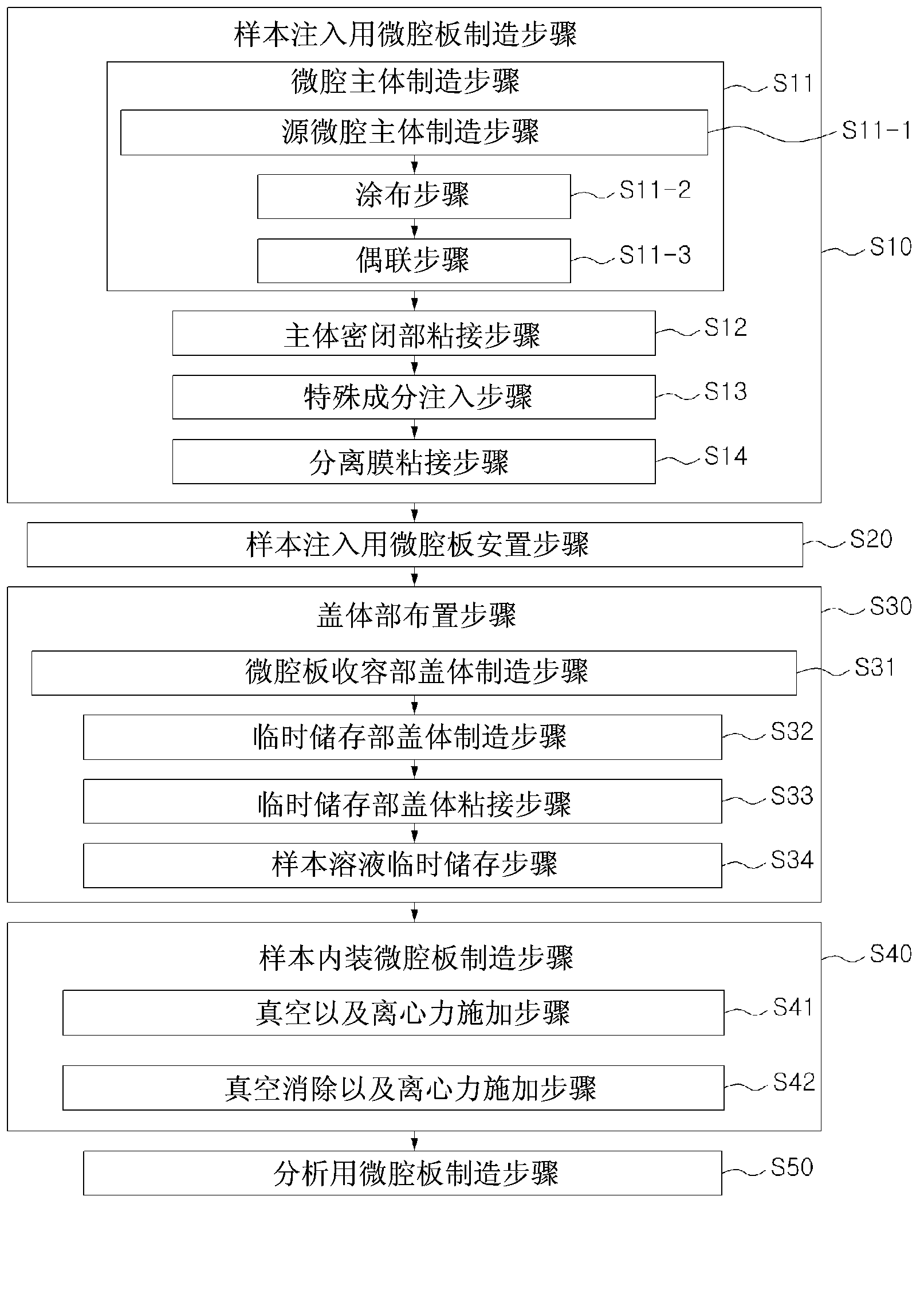

[0091] refer to figure 1 , Embodiment 1 includes the manufacturing step S10 of the microcavity plate for sample injection, the step S20 of arranging the microcavity plate for sample injection, the step S30 of arranging the cover body, the manufacturing step S40 of the microcavity plate containing the sample, and the manufacturing step S50 of the microcavity plate for analysis.

[0092] 1. Manufacturing step S10 of microcavity plate for sample injection

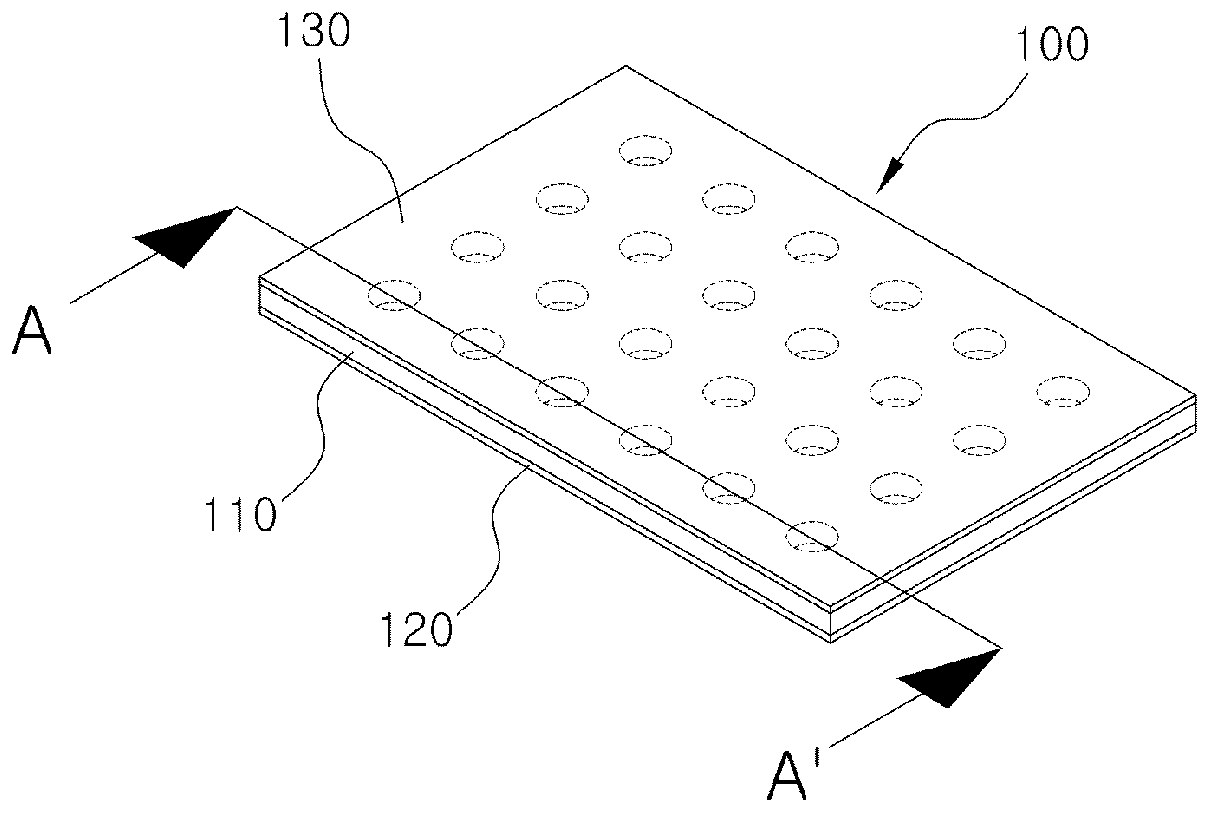

[0093] refer to Figure 2 to Figure 4 , in the microchamber plate manufacturing step S10 for sample injection, the microchamber plate 100 for sample injection containing the specific component 140 for analyzing nucleic acid including primers or probes is manufactured. The microchamber plate 100 for sample injection includes a microchamber body 110 , a body sealing portion 120 , and a separation me...

Embodiment 2

[0140] The second embodiment relates to the manufacturing method of the sample-containing microcavity plate provided by the present invention.

[0141] Embodiment 2 includes the manufacturing step S10 of the microcavity plate for sample injection, the step S20 of arranging the microcavity plate for sample injection, the step S30 of arranging the cover body, and the manufacturing step S40 of the microcavity plate with samples as described in Embodiment 1.

[0142] The description of this follows the description of the first embodiment.

Embodiment 3

[0144] The third embodiment relates to the analysis microcavity plate provided by the present invention. Analytical microcavity plates (not shown) except for the microcavity plate 100A inside the sample (refer to Figure 17 ) and the separation membrane 130 part, others are the same as above, so refer to Figure 17 Be explained.

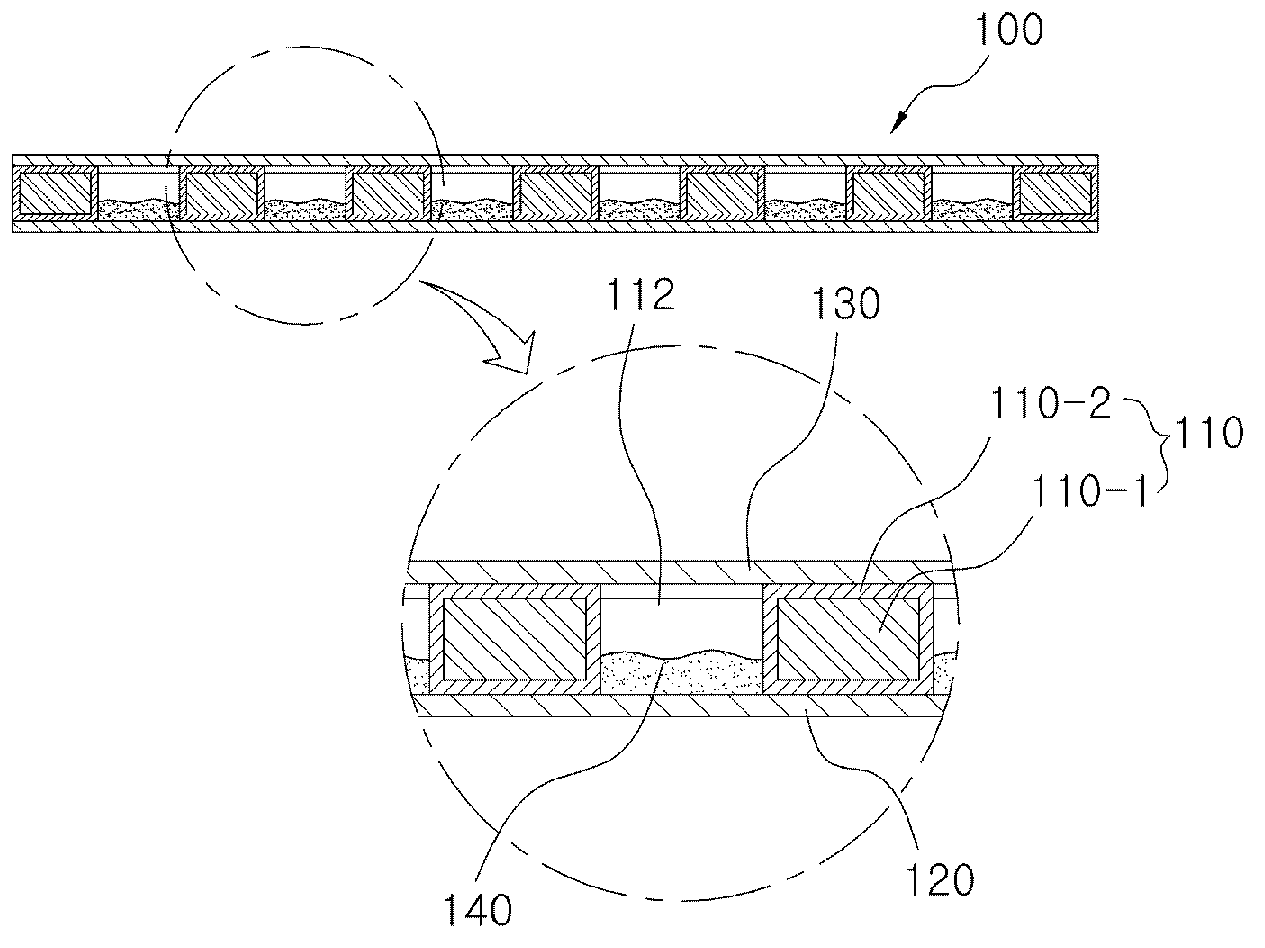

[0145] refer to Figure 17 as well as Figure 16 , the third embodiment has a source (origin) microcavity main body 110-1 that penetrates up and down to form a unit number of source (origin) cavity holes 110-1H.

[0146] refer to Figure 17 and Figure 7 , the surface of the source microcavity body 110-1 and the unit number of source cavity holes 110-1H (refer to Figure 6 ) forms a polymer coating layer 110-2 on the inner surface. According to the polymer coating layer 110-2, the source cavity hole 110-1H corresponding to the unit number is formed (refer to Figure 6 ) of the unit number of cavities 112 .

[0147] refer to Figure 17 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com