Flow line process method for automatic transplanting and repairing of printed circuit boards

A technology of printed circuit board and assembly line, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit assembly of electrical components, etc., and can solve problems such as difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the structure, features and purpose of the present invention, drawings and detailed descriptions of preferred specific embodiments are attached below.

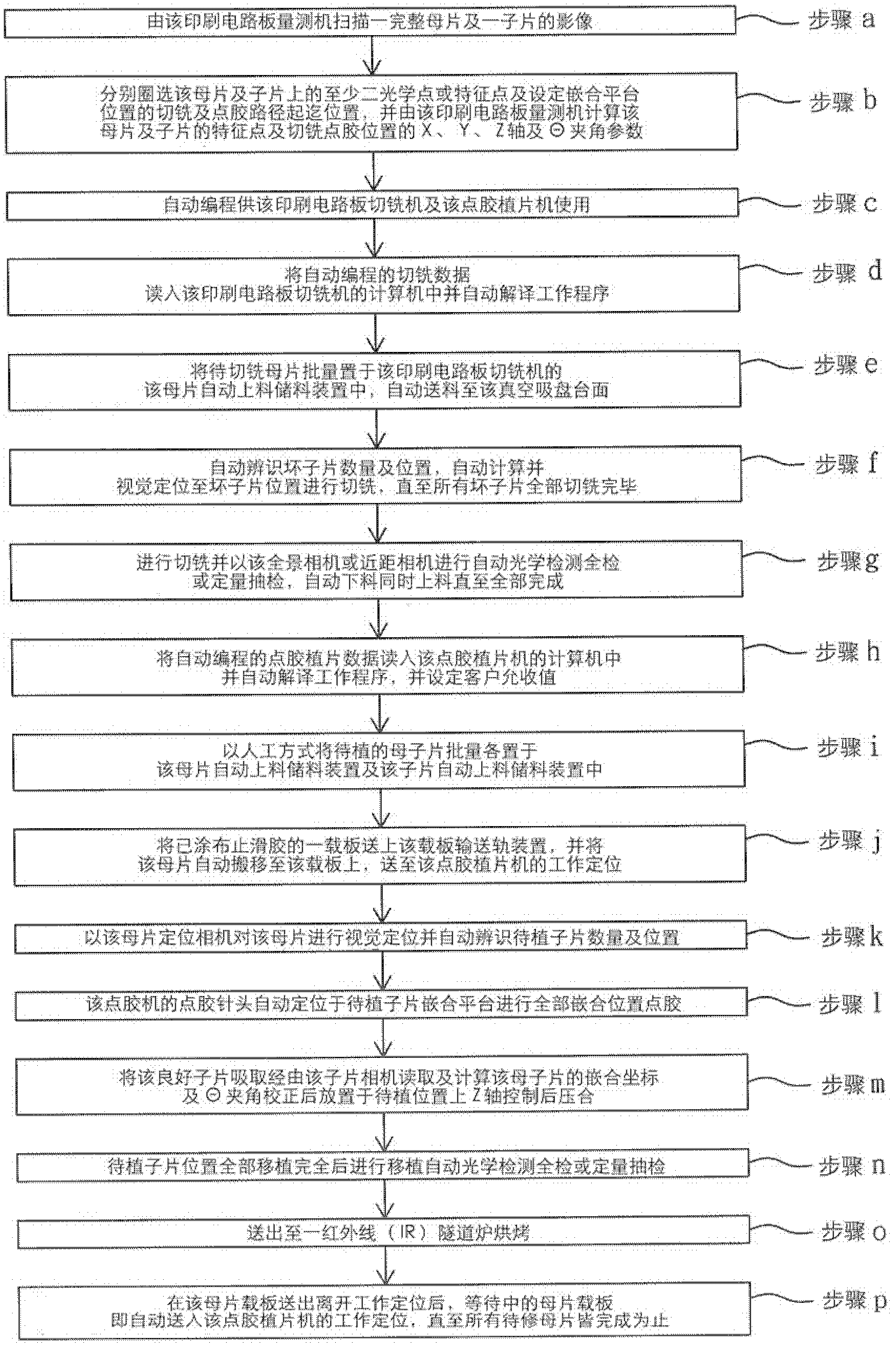

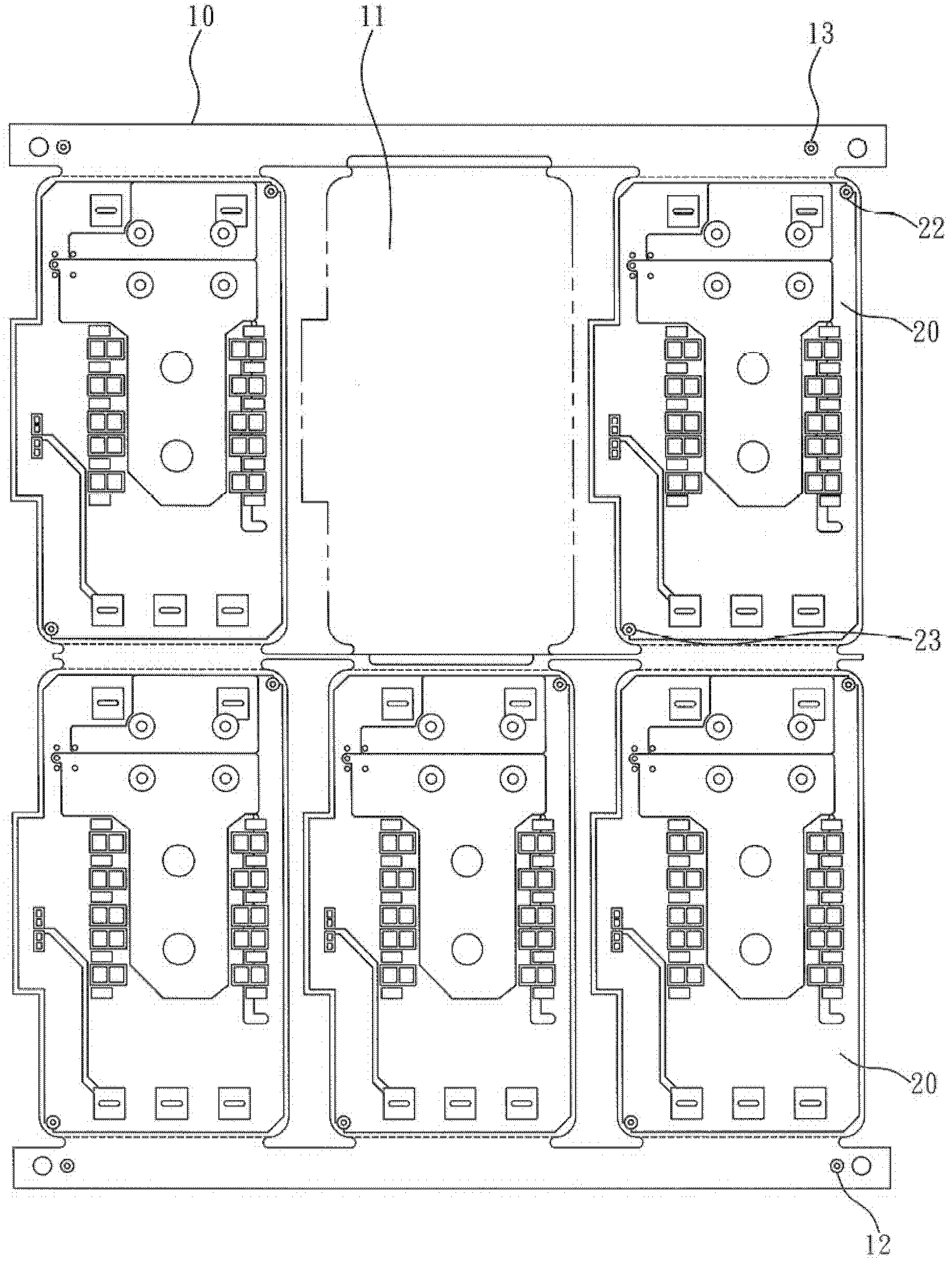

[0024] Please also refer to Figure 1 ~ Figure 2 ,in figure 1 A schematic flow diagram showing a pipelined process method for automatic transplantation and repair of printed circuit boards according to a preferred embodiment of the present invention; figure 2 A schematic diagram showing the master piece to be repaired and the good daughter piece before repairing according to the present invention.

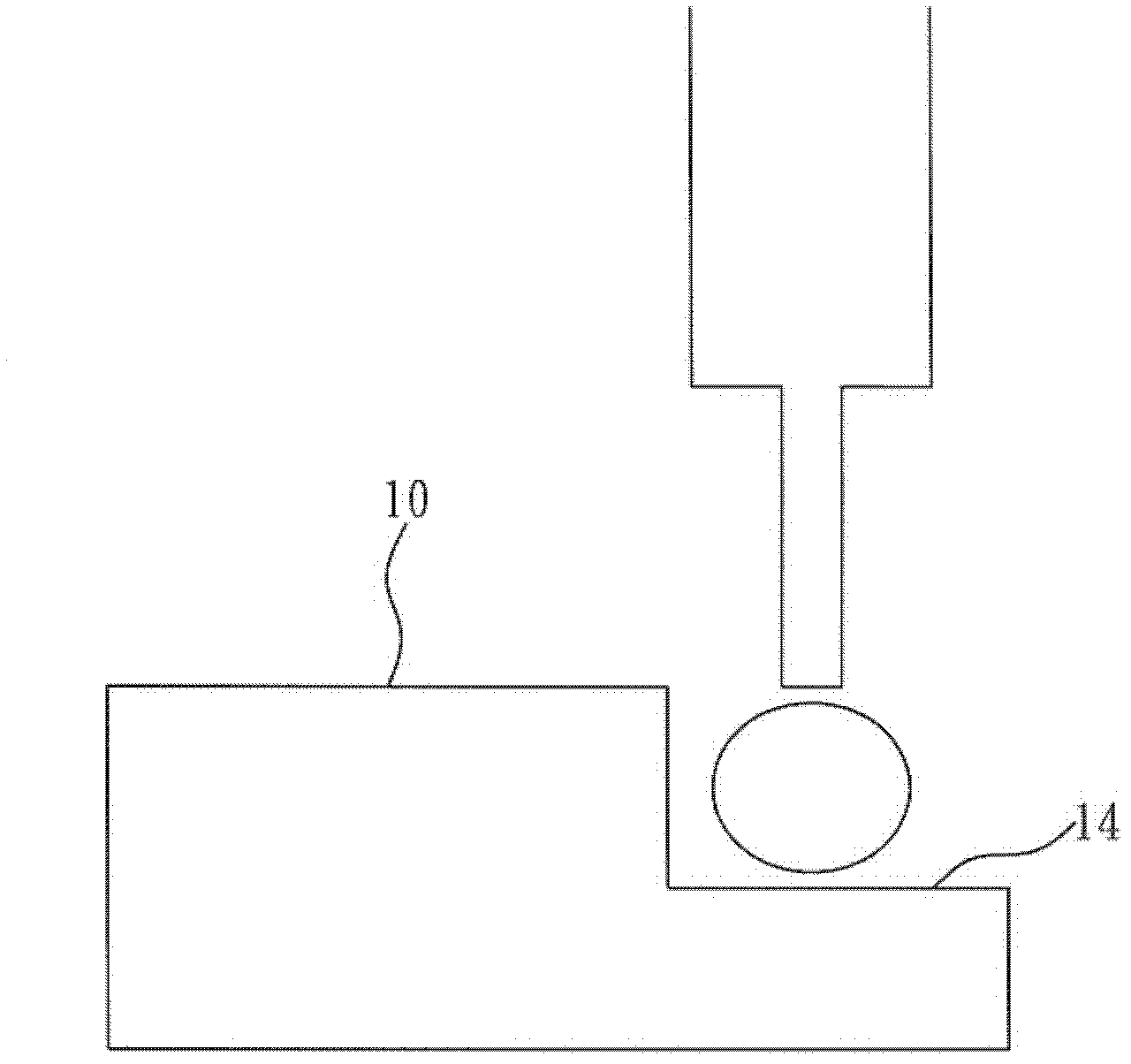

[0025] The purpose of the present invention is to carry out transplant repair of printed circuit board. Before repairing, a CNC printed circuit board cutting and milling machine (not shown) must be used to cut at least one bad sub-chip 20 from a mother chip 10 to be repaired, so that the good sub-chip on the mother chip 10 to be repaired The chip 20 can be reserved for continued use; wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com