Sulfur composite cathode material and preparation method thereof

A composite positive electrode material and positive electrode material technology, applied in the field of sulfur composite positive electrode material and its preparation, can solve problems that are not conducive to battery performance and single structure, and achieve the effects of inhibiting the shuttle effect, preventing agglomeration, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of sulfur composite cathode material, said method comprising the following steps:

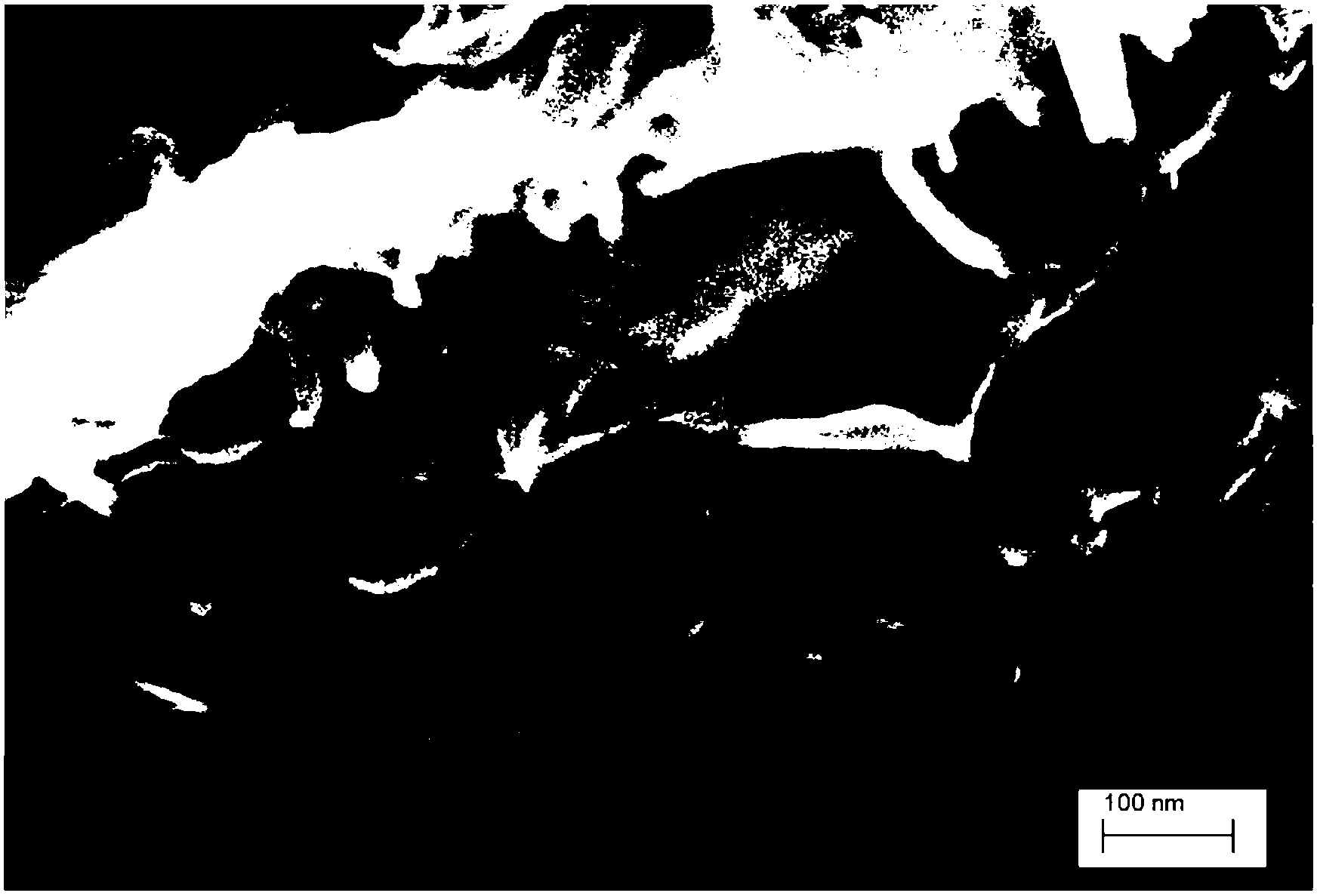

[0044] (1) Mix 4g of high-purity S powder (purity 99.5%, 325 mesh) with 1g of multi-walled carbon nanotubes, ball mill for 3 hours, place in a sealed polytetrafluoroethylene container filled with argon protection, and heat at 155°C Under heating for 24 hours, the sulfur-carbon nanotube composite material was obtained.

[0045] (2) Take 1 g of the sulfur-carbon nanotube composite material and ultrasonically disperse it in the alcohol / water liquid phase system for 1 hour to obtain a uniform black solution; the alcohol / water liquid phase system is ethanol / water (volume ratio 1:1), The total volume is 100ml;

[0046] (3) Add 50ml of graphene oxide solution with a concentration of 3mg / ml to the obtained solution, stir magnetically for 30min, and disperse in 150W ultrasonic for 1h to obtain a mixture;

[0047] (4) Put the mixture in an open container, stir and heat in an...

Embodiment 2

[0051] A preparation method of sulfur composite cathode material, said method comprising the following steps:

[0052] (1) Mix 4g of high-purity S powder (purity: 99.5%, 325 mesh) with 1g of multi-walled carbon nanotubes, ball mill for 3 hours, and place in a sealed polytetrafluoroethylene container filled with nitrogen protection, at 120°C Heated for 12 hours to obtain a sulfur-carbon nanotube composite material.

[0053] (2) Take 1 g of the sulfur-carbon nanotube composite material and ultrasonically disperse it in the alcohol / water liquid phase system for 1 hour to obtain a uniform black solution; the alcohol / water liquid phase system is methanol / water (volume ratio 1:2), The total volume is 100ml;

[0054] (3) Add 50ml of graphene oxide solution with a concentration of 1mg / ml to the obtained solution, stir magnetically for 30min, and disperse in 300W ultrasonic for 0.5h to obtain a mixture;

[0055] (4) Put the mixture in an open container, stir and heat in an oil bath, ...

Embodiment 3

[0060] (1) Mix 3g of high-purity S powder (purity 99.5%, 325 mesh) with 1g of single-walled carbon nanotubes, ball mill for 3 hours, and place in a sealed polytetrafluoroethylene container filled with nitrogen protection, at 155°C After heating for 24 hours, the sulfur-carbon nanotube composite material was obtained.

[0061] (2) Take 1g of sulfur-carbon nanotube composite material and ultrasonically disperse it in an alcohol / water liquid phase system for 1 hour to obtain a uniform black solution; the alcohol / water liquid phase system is propanol / water (volume ratio 2:1) , with a total volume of 100ml;

[0062] (3) Add 50ml of graphene oxide solution with a concentration of 3mg / ml to the obtained solution, stir it magnetically for 2 hours, and disperse it in 50W ultrasonic for 2 hours to obtain a mixture;

[0063] (4) Put the mixture in an open container, stir and heat in an oven, the heating temperature is 60°C, and the heating time is 72h, during which the water volatilized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com