A kind of miniature assembly line and its manufacturing method

A manufacturing method and technology for installing wires, which are applied in the manufacture of cables/conductors, conductors, insulated cables, etc., can solve the problems of the decrease of the smoothness of the outer wall of the insulating layer, the failure to meet the needs of the use environment, and the shortening of the service life of the conductors. Conducive to heat dissipation, high space utilization, and improved current-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

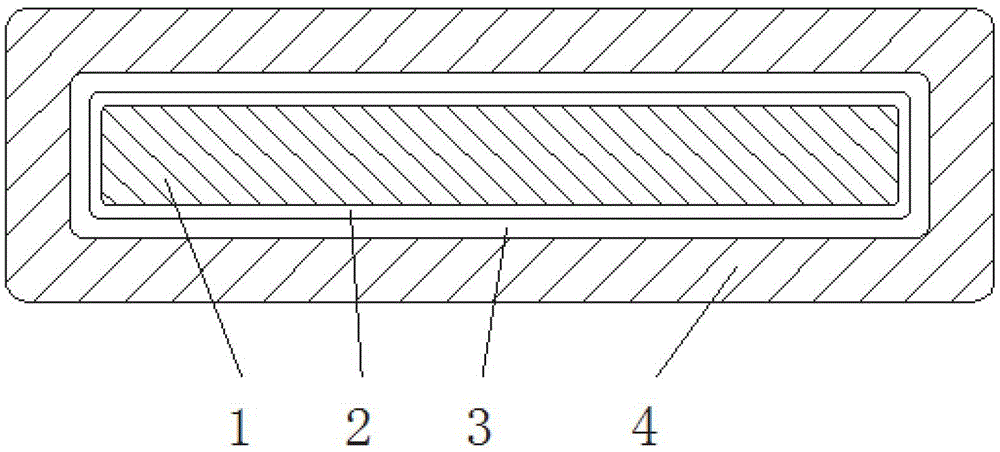

[0022] see figure 1 :

[0023] Miniature installation wire, including conductor 1, conductor 1 is a flat conductor, and the cross-sectional area of conductor 1 is generally 0.20~0.75mm 2 , the conductor 1 has a thickness of 0.10~0.20mm and a width of 2.0~3.75mm. The conductor 1 is provided with a silver-plated layer 2. The silver-plated layer 2 contains aluminum and nickel, and the content of aluminum and nickel is greater than or equal to the silver in the silver-plated layer. 5% of the total weight, wherein aluminum and nickel are prepared in equal proportions, the thickness of the silver-plated layer 2 is not greater than 0.1mm, and the outer layer of the silver-plated layer 2 is provided with an aluminum-plated layer 3, and the thickness of the aluminum-plated layer 3 is not greater than 0.08mm; Conductor 1. The insulating layer 4 is extruded with 125°C radiation cross-linked low-smoke halogen-free polyolefin insulating material. The thickness of the insulating layer 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com