Bonding process of solar condenser lens assembly

A solar concentrating and lens assembly technology, applied in solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problems of short service life of glue, poor bonding effect, low impact resistance, etc., and achieve firm bonding performance , The effect of strong bonding firmness and stable bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

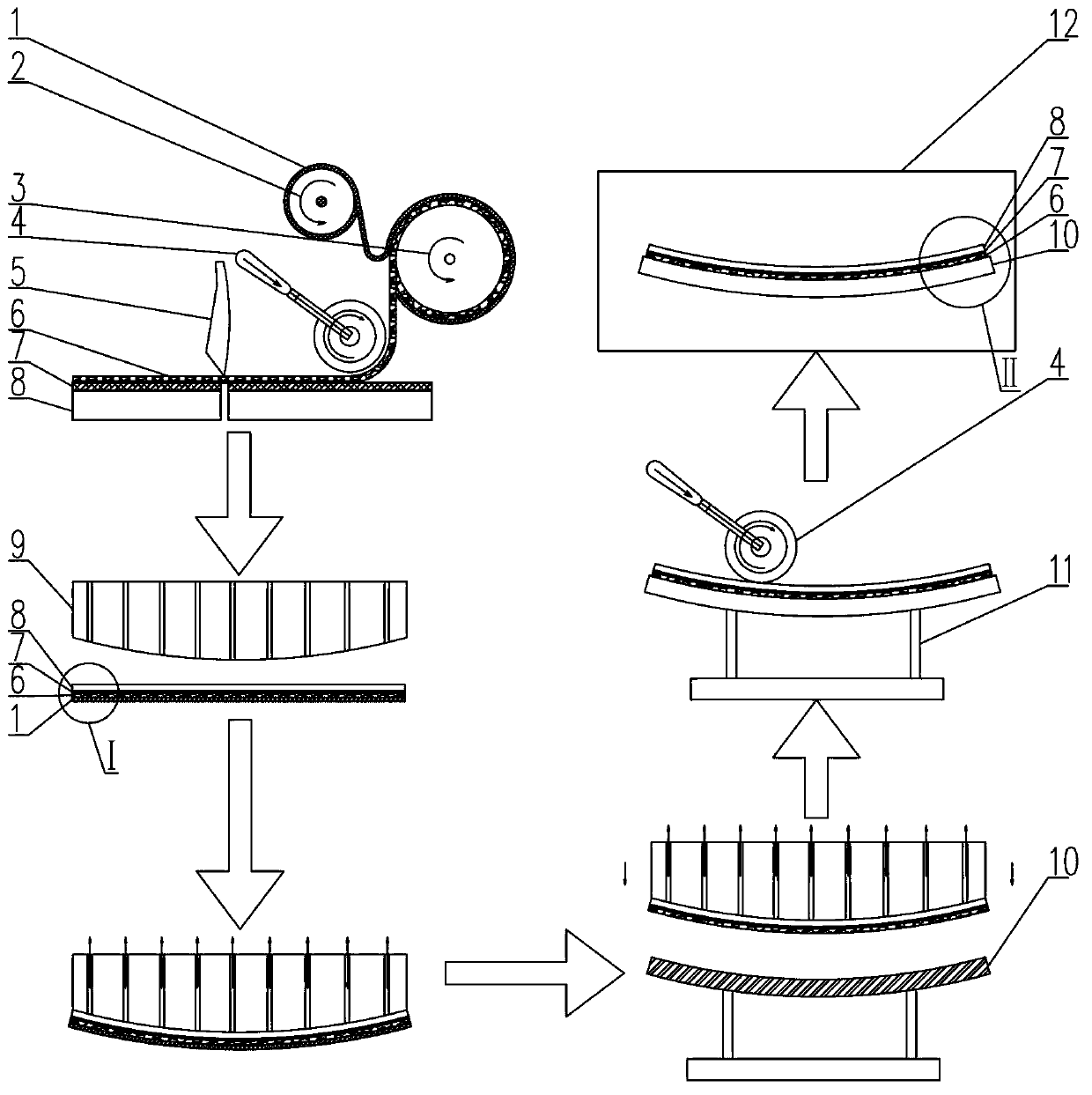

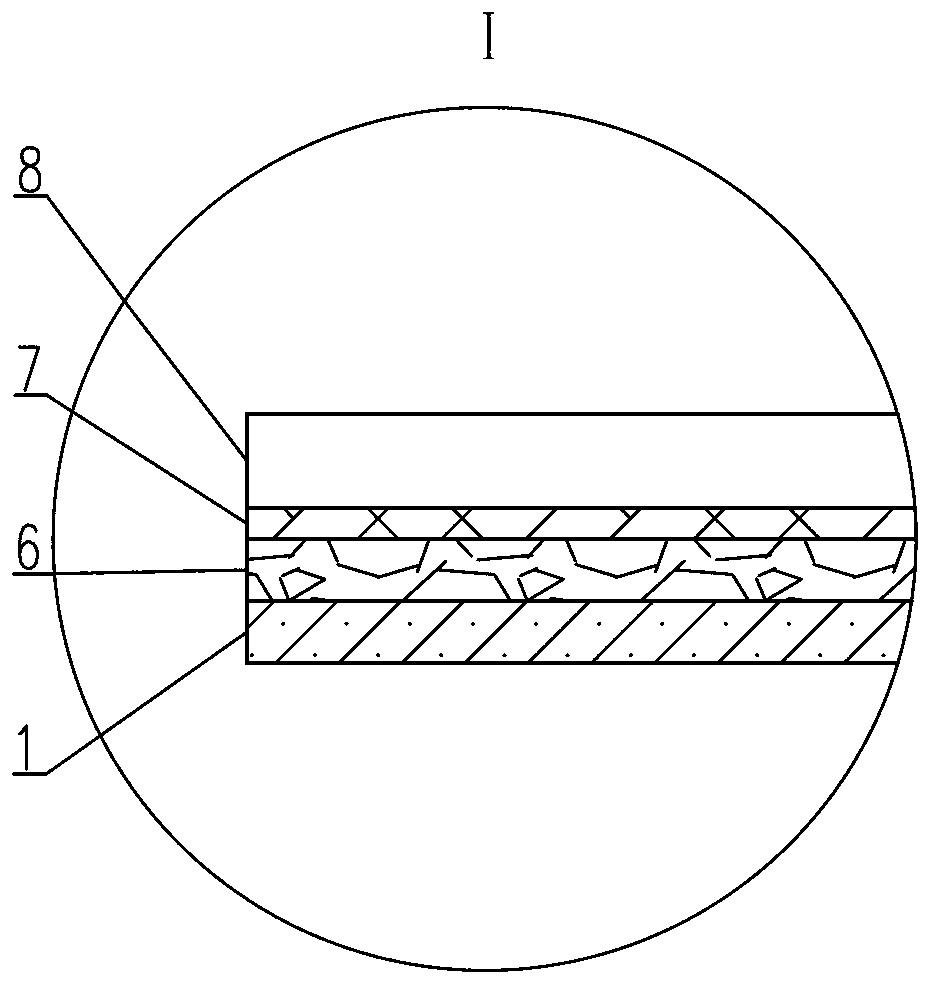

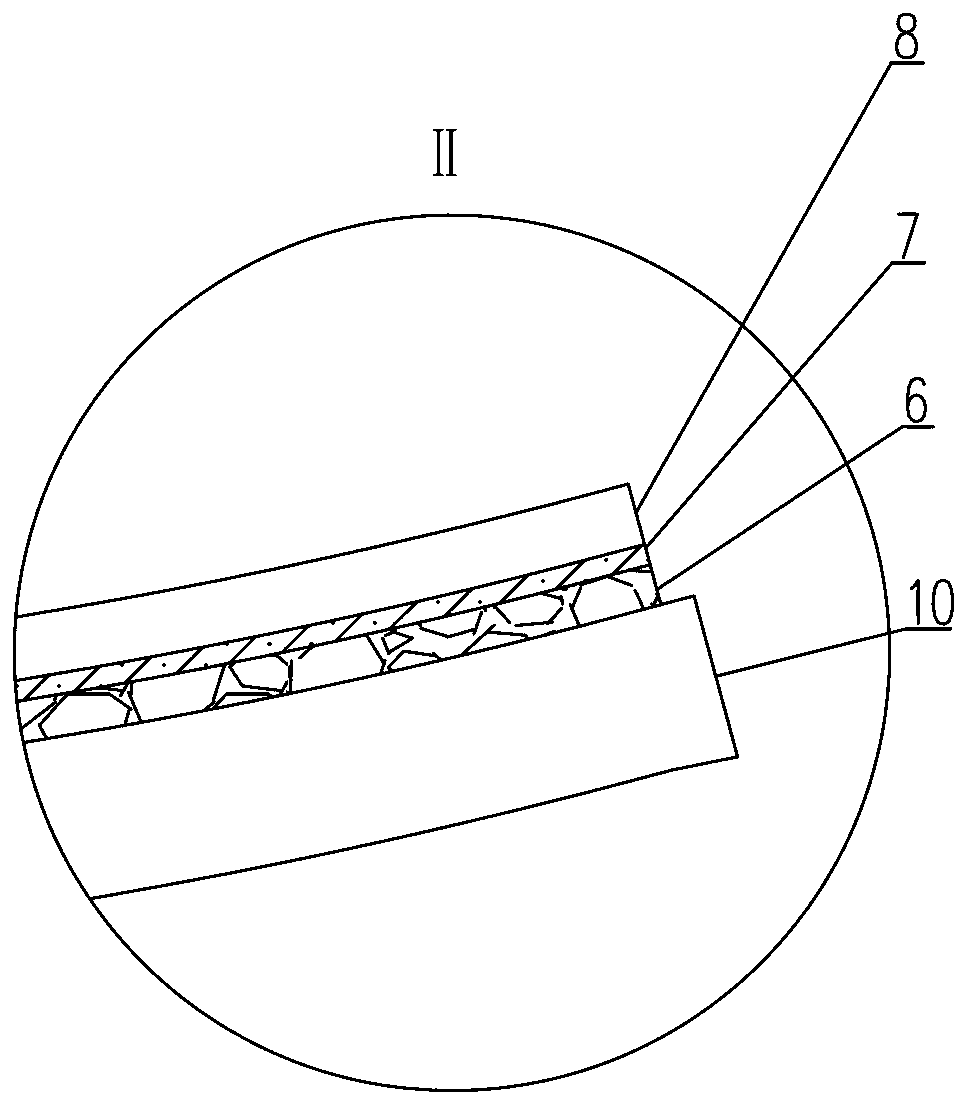

[0023] Such as figure 1 , figure 2 and image 3 A bonding process for a solar concentrating lens assembly shown, comprising the steps of:

[0024] Step 1: After cleaning and drying, the lenses divided according to certain specifications are tiled on the operation platform or the conveyor belt of the assembly line according to the paint surface facing upwards and a certain distance between the lenses;

[0025] Step 2: Align one end of the pressure-sensitive adhesive film with one end of the lens, and glue the lower surface of the pressure-sensitive adhesive film to the paint surface of the lens; rotate the roller of the pressure-sensitive adhesive tape and use the elastic push roller to gradually push the pressure-sensitive adhesive film to the other end of the lens, and at the same time The release paper on the lower surface of the pressure-sensitive adhesive film is driven to rotate by the release paper recovery roller;

[0026] Step 3: Cut and separate the pressure-sensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com