Combined vibration isolation base with hollow webs

A hollow plate and combined technology, applied in the field of power equipment installation base, can solve the problems of ship vibration isolation effect is not obvious, no vibration and noise reduction, etc., to achieve good low-frequency vibration absorption effect, attenuation of structural noise transmission, good The effect of practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

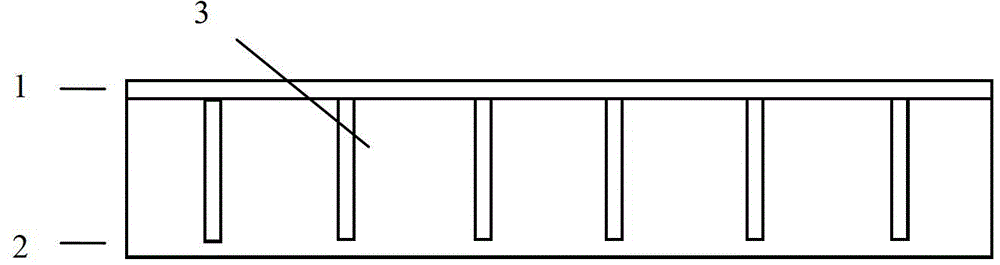

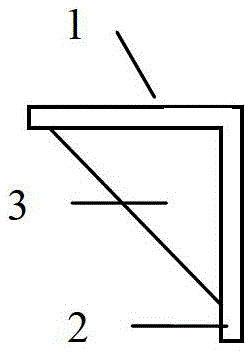

[0032] Figure 1(1) and Figure 1(2) show a typical ship base structure, which consists of base transverse panel 1, base vertical panel 2 and base bracket 3, the structure can only To the role of installing and supporting power equipment, there is almost no effect of vibration and noise reduction.

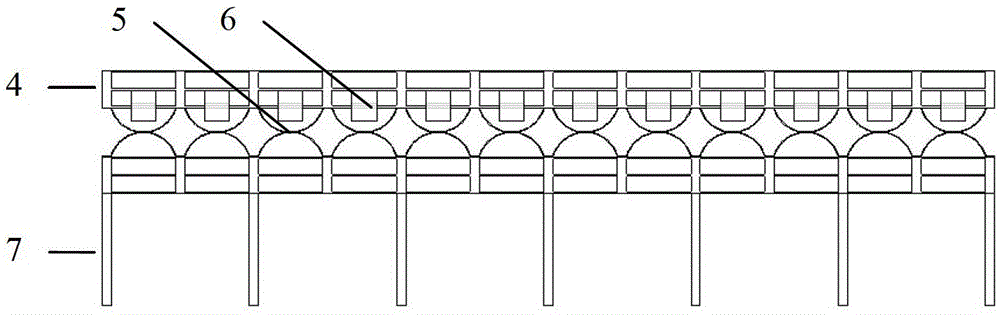

[0033] Fig. 2(1) and Fig. 2(2) show a new type of combined hollow plate vibration isolation base structure disclosed by the present invention, which consists of double-layer periodic hollow plate 4, curved beam spring 5, cantilever beam type power The shock absorber 6 and the arc connecting plate 7 are welded. The doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com