Buffer device

A technology of buffer device and cylinder, which is used in projectiles, self-propelled projectiles, offensive equipment, etc., can solve the requirements of local structural strength and rigidity of satellite connection points and high concentrated force diffusion, and the work of pyrotechnic separation nut has large impact and influence. Problems such as the use of instruments and equipment, to achieve the effect of less protruding payload structure, lightweight, and small space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

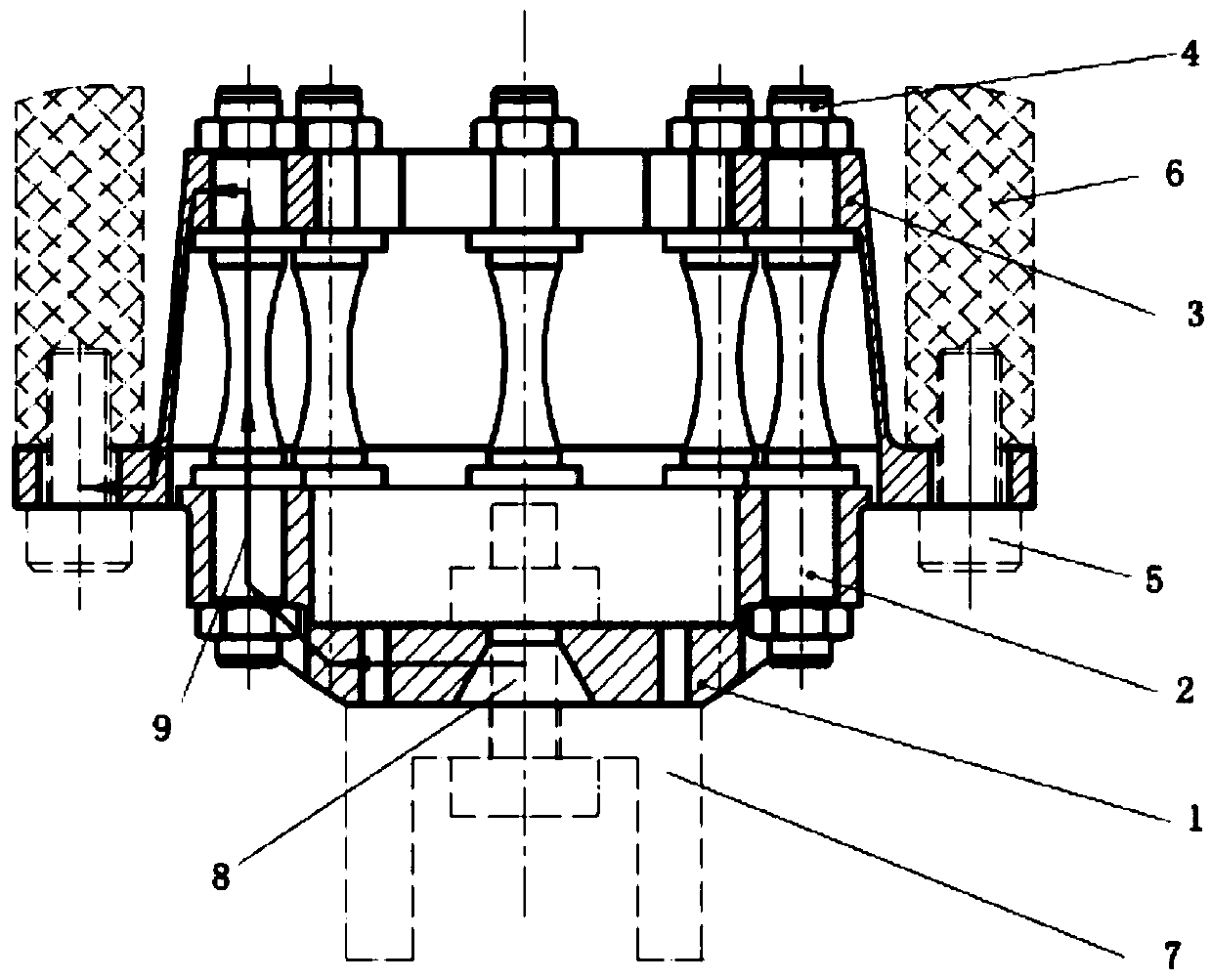

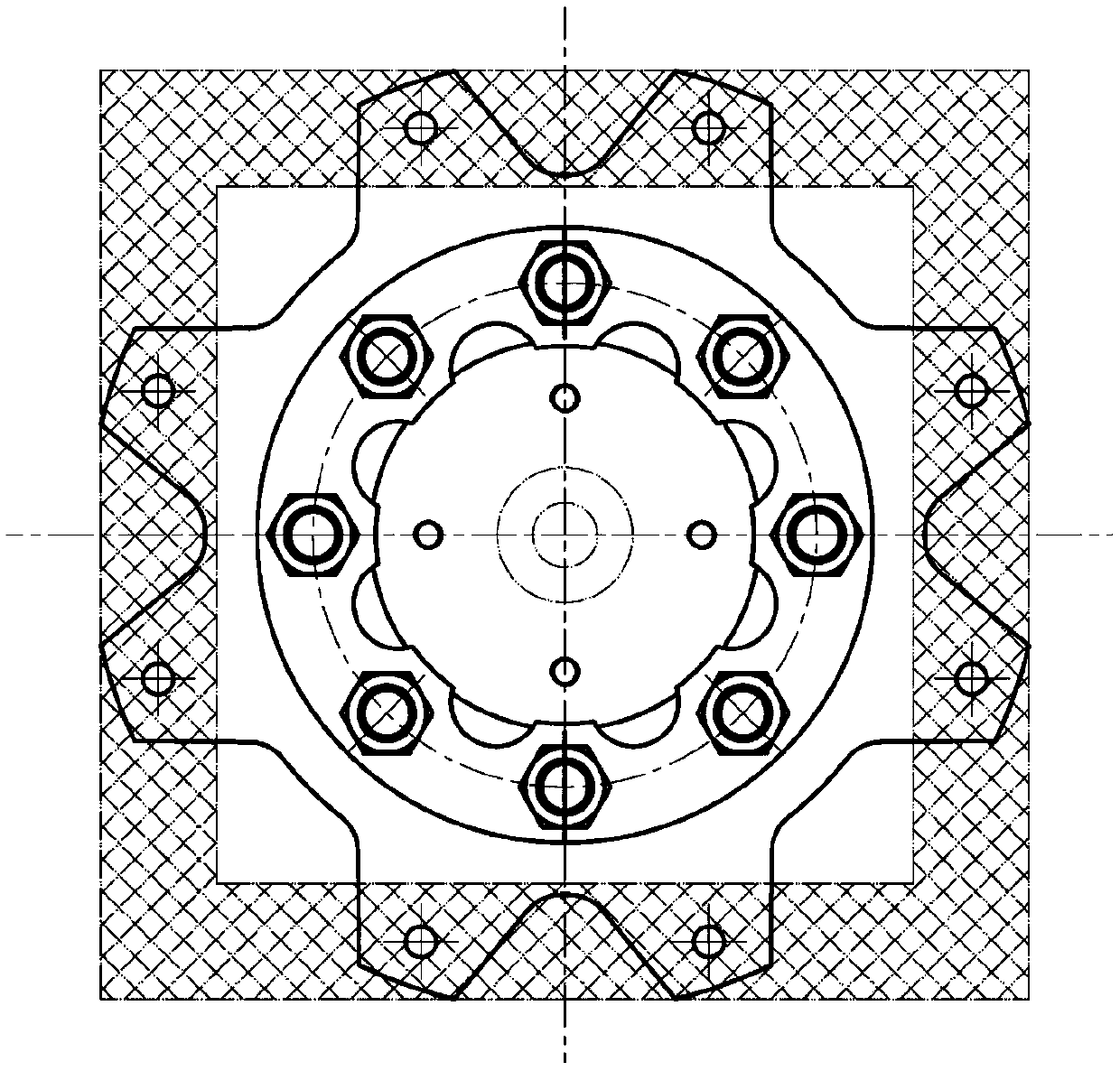

[0024] The present invention provides a buffer device, comprising: a flange 1, a stud bolt 2, a buffer cap 3 and a fastener 4, a through hole is provided in the center of the flange 1, and the through hole includes superimposed conical holes and cylindrical holes, used to connect the carrying system connection structure 7, around the circumference are provided with a number of screw holes, the distance between the screw holes and the center of the flange 1 is equal; the unilateral section of the buffer cap 3 is Z-shaped, the upper end The flange is provided with cylindrical through holes that match the size and number of screw holes on the flange around the central axis, and the positions correspond to the cylindrical through holes. The flange flanges are 8 trapezoidal lugs, and the trapezoidal lugs are provided with screw holes, which are connected to the payload connection structure 6 through the connecting bolt 5; the two ends of the stud bolt 2 are threaded cylindrical stru...

Embodiment 2

[0028] The difference between this embodiment and embodiment 1 is:

[0029] The stud bolt 2 is a cylindrical structure with threads at both ends, and the stud bolt is provided with a limit protrusion at a certain distance from the two ends, which cooperates with the fastener 4 to jointly limit and fix the flange 1 and buffer cap 3.

[0030] Apart from this, other aspects of this embodiment are the same as those of Embodiment 1, and are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com