Rear suspension oil cylinder for heavy-duty industrial mining vehicle

A technology of rear suspension and mining, applied in the field of hydraulic cylinders, can solve the problems of large suspension space, inability to adapt to the lightweight of heavy-duty chassis, inability to take into account chassis comfort and handling stability at the same time, and achieve the effect of ensuring smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

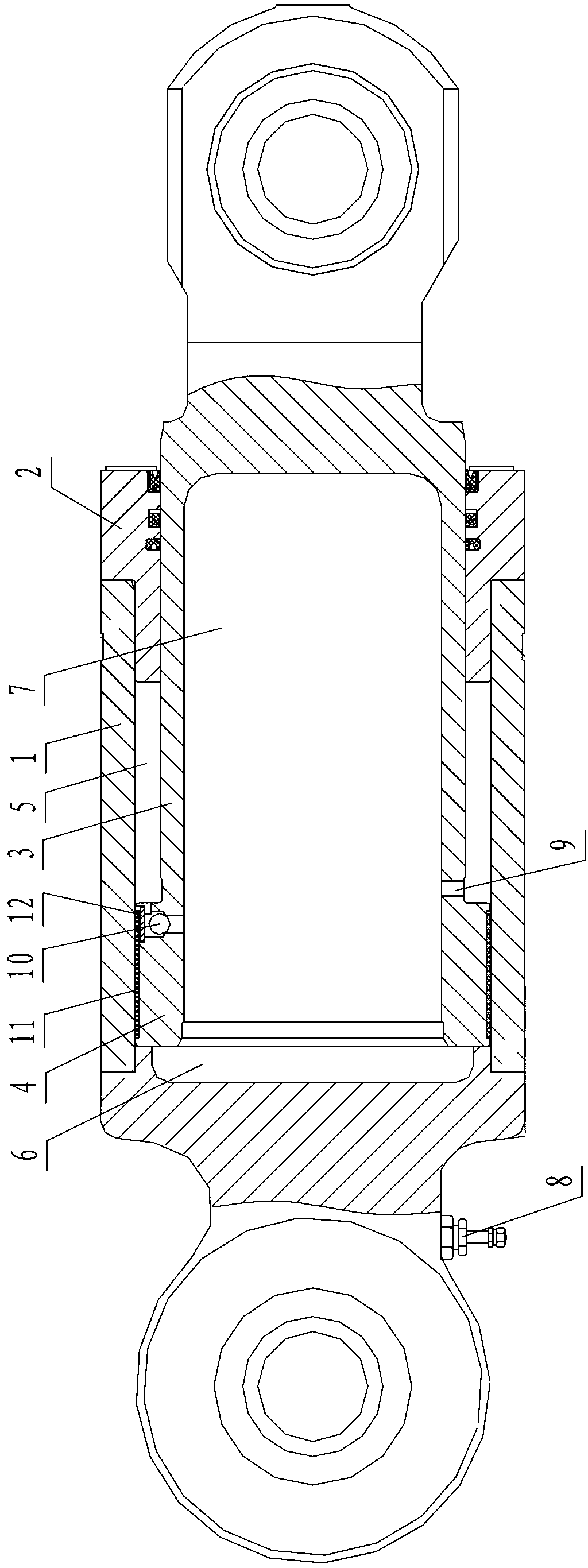

[0010] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0011] Such as figure 1 The shown rear suspension oil cylinder for a heavy industrial and mining vehicle is installed at the rear of the vehicle to support the upper and lower frames. It includes a cylinder body 1 with an open front end and a closed rear end, a guide sleeve 2 installed at the front end opening of the cylinder body 1, a piston rod 3, and a piston 4 located at the rear end of the piston rod 3 and integrally structured with the piston rod 3, wherein the cylinder The body 1 is welded and combined by the rear cover and the cylinder body, the piston rod 3 is in fluid-tight sliding fit with the guide sleeve 2, the piston 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com