Rotary compressor and exhaust valve

A rotary compressor and exhaust valve technology, applied in the field of compressors, can solve problems such as complex structure and complicated procedures, and achieve the effects of improving performance, eliminating noise and energy loss, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

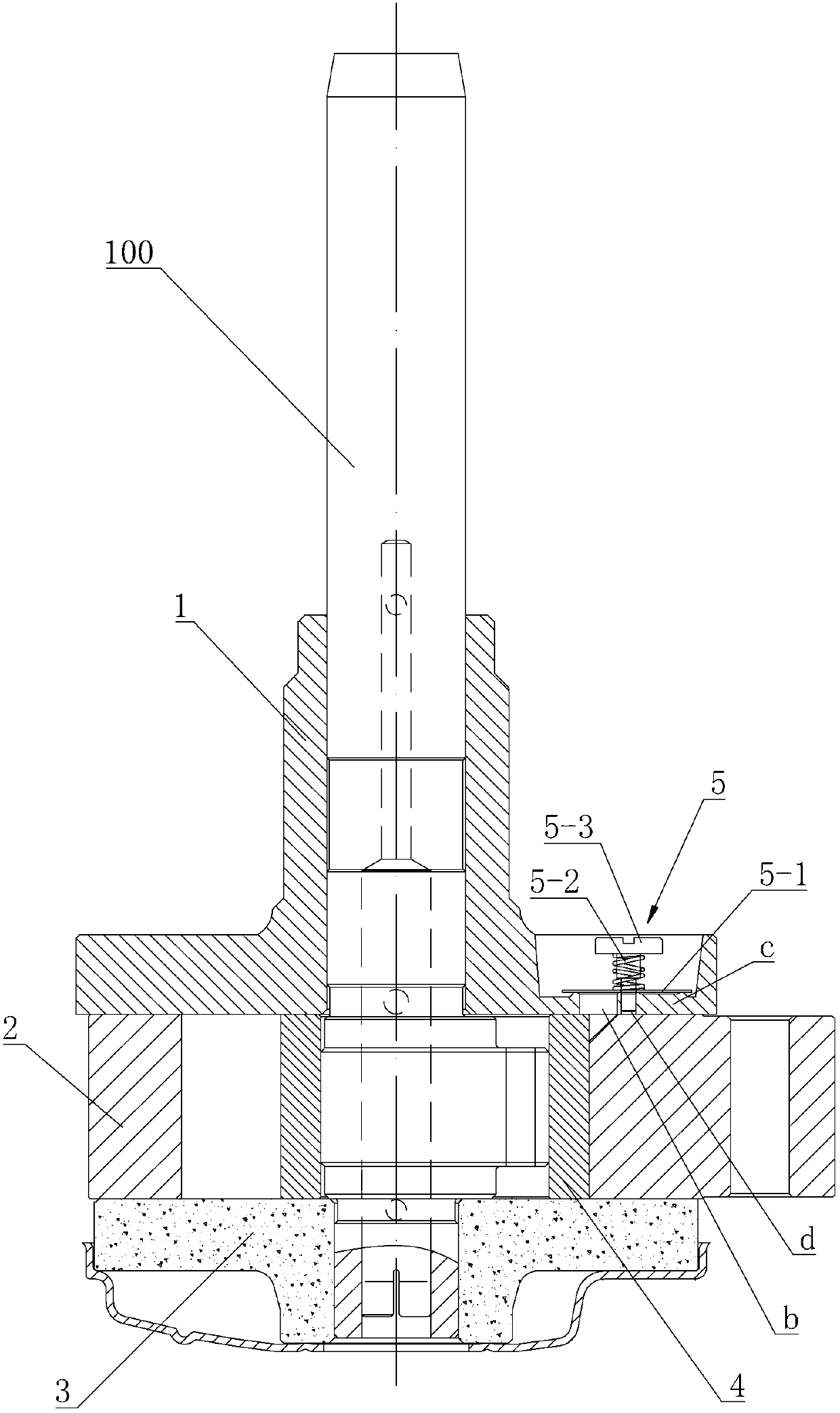

[0023] The rotary compressor of the present invention comprises a closed casing, a motor and a compression pump body arranged inside the closed casing, a gas-liquid separator arranged on one side of the closed casing, and the gas-liquid separator is connected to the compressor through an intake elbow. The compression pump body is connected, so that the refrigerant enters the cylinder of the compressor from the gas-liquid separator, and the compressed high-temperature and high-pressure gas enters the circulation system from the exhaust pipe.

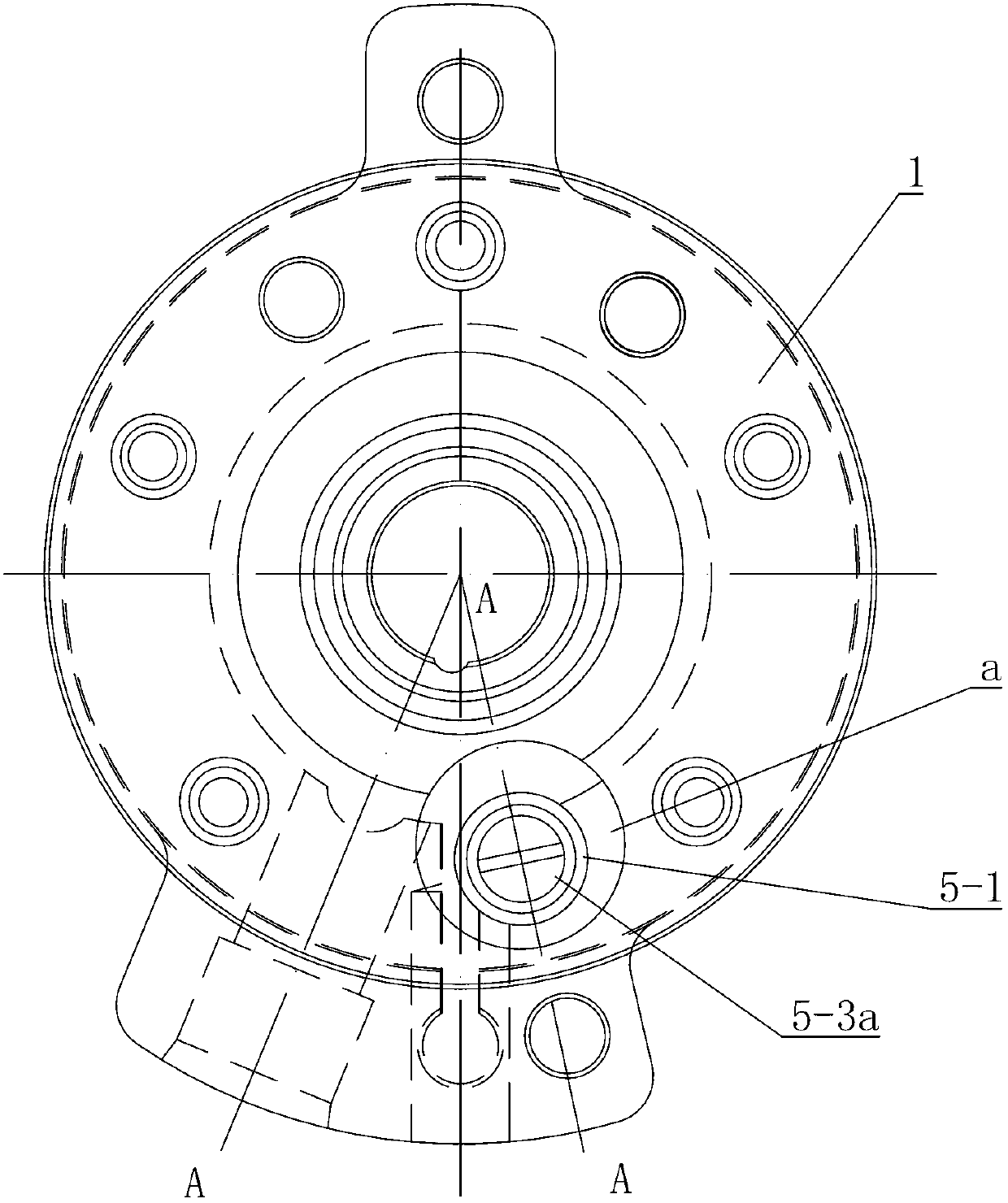

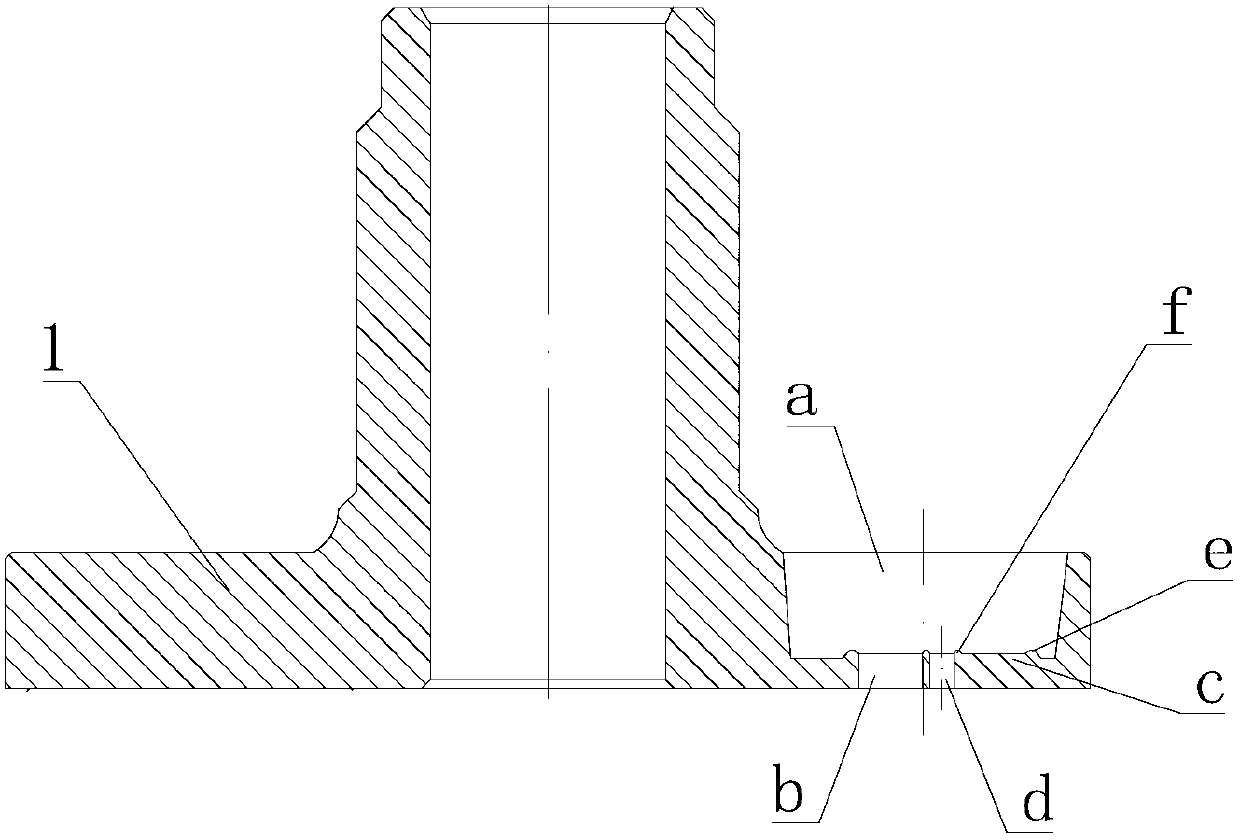

[0024] Such as figure 1 and figure 2 As shown, the compression pump body of the present invention includes an upper flange 1, a cylinder 2, a lower flange 3 arranged in sequence along the axial direction of the compressor crankshaft 100, and a roller 4 arranged in the cylinder 2, and the roller 4 is fixed in the compression On the eccentric part of the crankshaft 100 of the compressor, the roller 4 rolls along the inner wall of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com