Bleaching method for preparing high quality low pollution bamboo wood dissolving slurry

A low-pollution, dissolving pulp technology, applied in the post-processing of cellulose pulp, textiles and papermaking, papermaking, etc., can solve the problems of reaction performance, filtration performance deterioration, dynamic viscosity dispersion range expansion, fiber strength reduction and other problems, to achieve fine Low fiber production, reduced organic chloride content, and high product quality

Active Publication Date: 2013-03-27

四川天竹竹资源开发有限公司

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

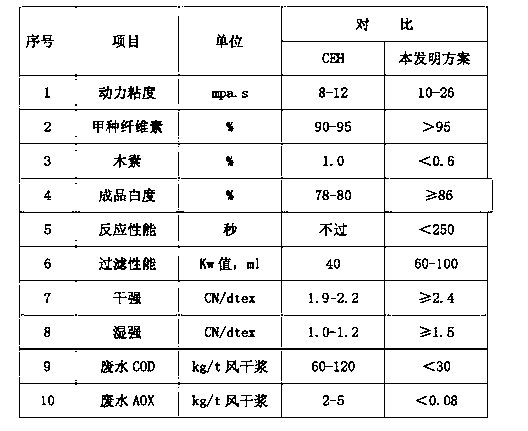

[0005] If the conventional CEH bleaching is still used, in order to achieve the purpose of improving the pulp whiteness and continuing to remove residual lignin, the only option is to use strong chlorine for oxidation treatment , the result is that the fiber strength drops sharply, the dispersion range of dynamic viscosity expands, and the uniformity cannot be guaranteed; the reaction performance and filtration performance deteriorate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0074] Sieve pulp concentration 0.7%.

[0075] Sieve plate specification Φ0.10mm.

[0076] Pulp purity: 200kgCOD / adt.

Embodiment 2

[0078] Sieve slurry concentration 2.5%.

[0079] Sieve plate specification Φ2.5mm.

[0080] Pulp purity: 100kgCOD / adt.

Embodiment 3

[0082] The sizing concentration is 0.5%.

[0083] The temperature is 50°C.

[0084] Pulp purity: 150kgCOD / adt.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a bleaching method for preparing a high quality low pollution bamboo wood dissolving slurry, which comprises the following steps: 1) removing parenchyma cells, employing a sieve method or a slurry washing method for removing parenchyma cells; 2) performing an oxidation reaction to remove a transition metal compound, removing boiled residual lignin in the unbleached slurry, performing ozone bleaching on washed slurry; 3) refining alkali in a reinforced mode; 4) bleaching chlorine dioxide; and 5) processing by acidifying at high temperature. According to the invention, delignification step by step, dynamic viscosity adjusting, whiteness enhancement, fine fiber generation reduction, and reaction capability activation are carried out on unbleached bamboo wood dissolving slurry, on the basis of increasing fiber strength, whiteness and filtering quality, the pollution load of the bleaching waste water is reduced, the bamboo wood dissolving slurry with high product quality and low environmental pollution is prepared, and provides a high quality raw material for producing the viscose fiber.

Description

technical field [0001] The invention relates to a bleaching method of high-quality and low-pollution bamboo dissolving pulp that can improve the reaction performance and strength of the dissolving pulp, improve the filtration performance and reduce environmental pollution, especially relates to a method of using bamboo as raw material to remove miscellaneous cells→ Oxidation reaction→intensified alkali refining→chlorine dioxide bleaching→high temperature acidification treatment to prepare a bleaching method for preparing high-quality and low-pollution bamboo dissolving pulp with good reaction ability, high filtration performance and less environmental pollution, which belongs to the fiber pulp manufacturing technology field. Background technique [0002] The traditional non-cotton cellulose dissolving pulp bleaching method mainly adopts the CEH three-stage bleaching method with high chlorine content, namely chlorination (C), alkalization (E), and hypochlorite (H) bleaching. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21C9/153

Inventor 王进军丛之敏赵建芬张佰丰薛振军

Owner 四川天竹竹资源开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com