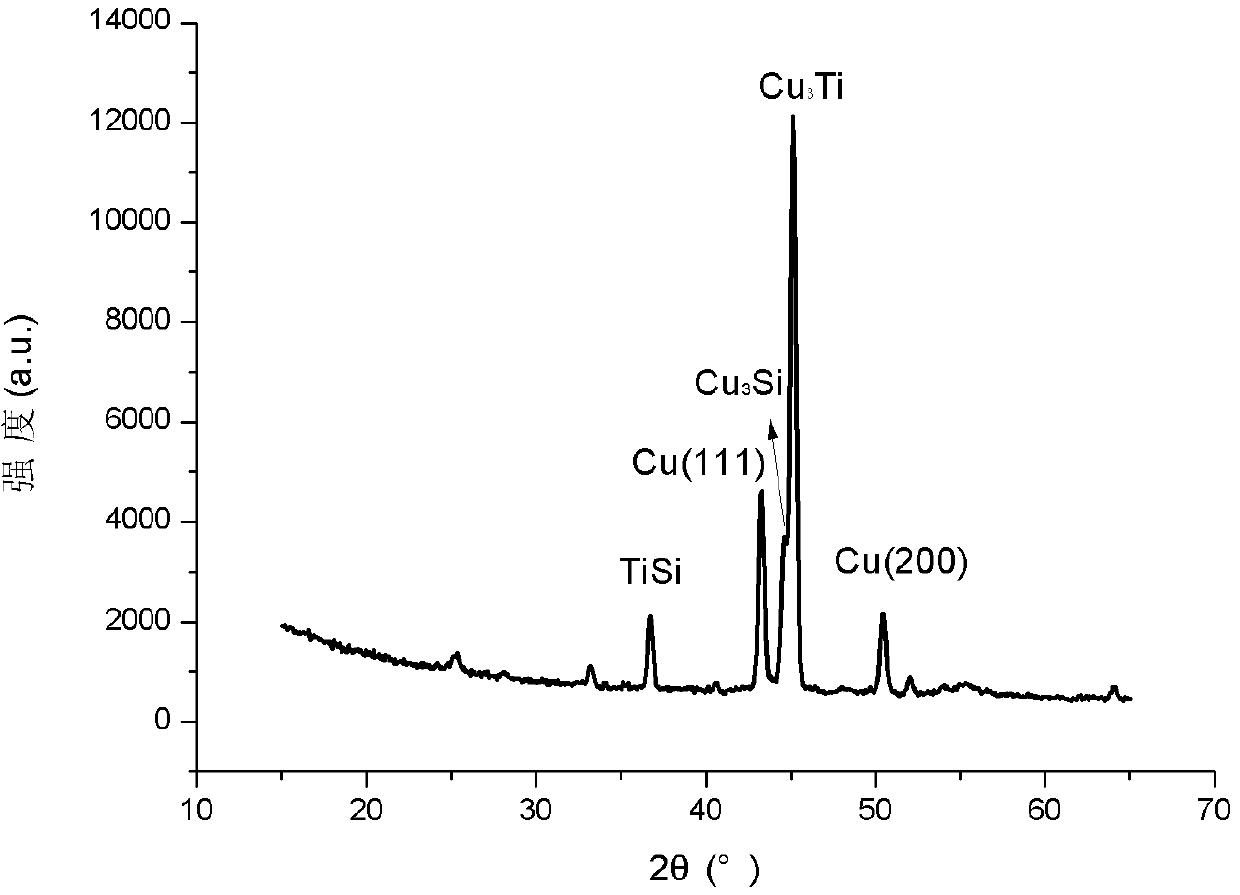

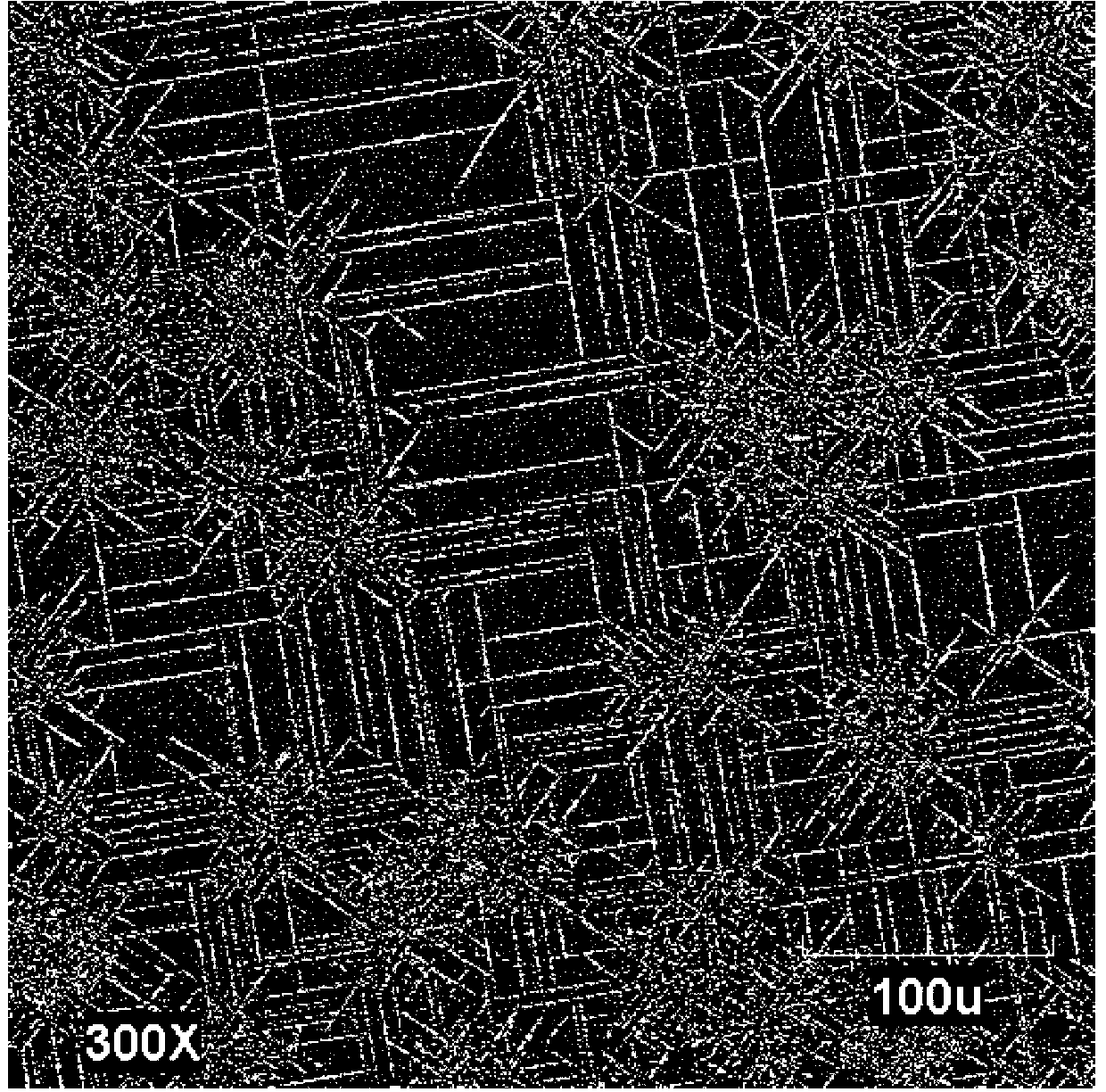

Method for generating dendritic crystal pattern on surface of Cu/Ti film

A film and pattern technology, applied in the field of preparation of Cu/Ti film dendrite pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] A kind of preparation technology of Cu / Ti film surface dendrite pattern, concrete steps are as follows:

[0016] Silicon wafer cleaning: use single-sided polished (100) silicon wafers as the substrate, and ultrasonically clean them with acetone, absolute ethanol, and deionized water for 15 minutes before sputtering, and then dry them for half an hour.

[0017] Sputtering: Cu / Ti thin film was prepared by Explorer14 sputtering machine produced by Denton Vacuum Company in the United States; Cu target and Ti target were respectively installed on two DC sputtering target guns, and the purity of both targets was 99.999% . Before sputtering, put the cleaned silicon wafer into the sputtering chamber and evacuate to 2×10 -5 Pa. The continuous sputtering method is used to sputter the Ti film on the silicon wafer first, and then sputter the Cu film. The sputtering powers of Cu and Ti are 99w and 105W respectively, and the sputtering rates are 0.4nm / s and 0.12nm / s respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com