Process for recovering lead, zinc and cadmium in soot on recovery section in process of treating waste acid generated in lead smelting

A lead smelting and polluting acid technology, applied in the direction of improving process efficiency, can solve the problems of not mentioning zinc recovery, affecting treatment, low metal recovery rate, etc., so as to reduce the difficulty of treatment, reduce treatment costs, and low operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

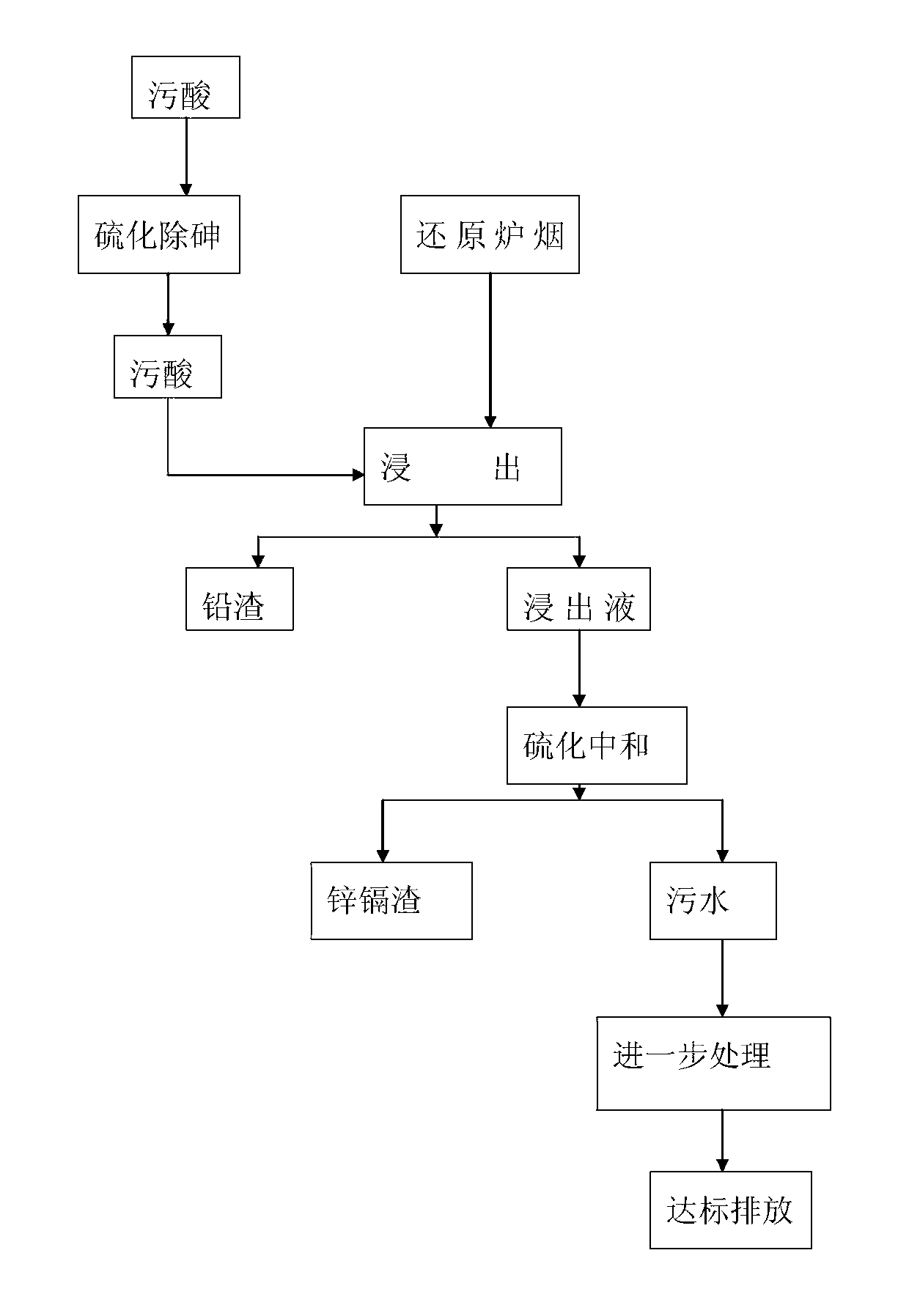

[0025] Such as figure 1 As shown, the process of recovering lead, zinc and cadmium in the soot in the reduction section during the treatment of lead smelting sewage acid includes the following steps:

[0026] Under the condition that the pH value is 0-2, add 1.44-2.16kg of sodium sulfate powder to 1000kg of lead smelting acid with arsenic content of 800ppm, and stir, the reaction produces arsenic sulfide precipitation, after the reaction stops, Filtrate to obtain the lead smelting dirty acid after sulfidation and arsenic removal, and the arsenic content in the lead smelting dirty acid after sulfidation and arsenic removal is less than 100ppm;

[0027] Add reduction furnace soot to the lead smelting sewage acid after sulfidation and arsenic removal according to the amount of 80-500g of reduction furnace soot per liter of sewage, and then stir for 20-30 minutes. When the pH value of the solution reaches 4-5.5, stop stirring and react Zinc and cadmium oxides in post-reduction fu...

Embodiment 2

[0032] Under the condition that the pH value is 0-2, add 1.44-2.16kg of sodium sulfate powder to 1000kg of lead smelting acid with arsenic content of 600ppm, and stir, the reaction produces arsenic sulfide precipitation, after the reaction stops, Filtrate to obtain the lead smelting dirty acid after sulfidation and arsenic removal, and the arsenic content in the lead smelting dirty acid after sulfidation and arsenic removal is less than 100ppm;

[0033] Add reduction furnace soot to the lead smelting sewage acid after sulfidation and arsenic removal according to the amount of 80-500g of reduction furnace soot per liter of sewage, and then stir for 20-30 minutes. When the pH value of the solution reaches 4-5.5, stop stirring and react Zinc and cadmium oxides in post-reduction furnace soot react with acid to dissolve into the solution, and lead oxides form lead sulfate to precipitate, which is leached and filtered to obtain lead slag and leachate, and the obtained lead slag is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com