Steam thermal cycle sludge drying method and system

A sludge drying and thermal cycle technology, applied in dehydration/drying/concentrated sludge treatment, etc., can solve the problems of unused water vapor, odor consumption of circulating cooling water, etc., to save material consumption and facilitate heat recovery , the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

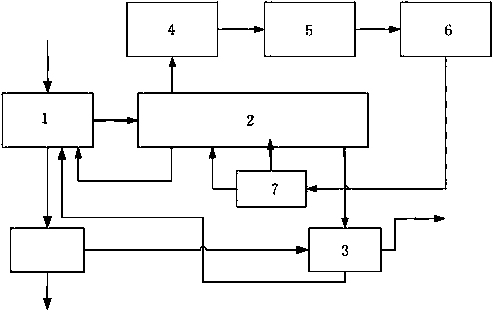

Image

Examples

Embodiment Construction

[0026] The invention provides a method for drying sludge by steam heat circulation, comprising the following steps:

[0027](1) Before the sludge is dried, use steam condensate to preheat the wet sludge to 50-80 degrees Celsius in an airtight environment that can discharge a small amount of non-condensable gas, thereby reducing the amount of sludge caused by sludge during the drying process. If the surface temperature of the sludge is too low, the surface steam will condense, thereby improving the evaporation efficiency of the sludge. After heat exchange, the heat exchange condensate with a temperature higher than room temperature is adjusted and purified, and the water temperature drops to room temperature, and the heat exchange condensate lowered to room temperature is used as the heat-absorbing medium for drying sludge or part of it is used as the absorber for sludge cooling. The heat medium and the remaining part of the heat exchange condensate are discharged as waste wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com