Slaughter wastewater flocculating agent

A technology of slaughtering wastewater and flocculant, which is applied in the field of flocculants and flocculants for slaughtering wastewater treatment, can solve the problems of unpleasant odor, high content of suspended solids, difficult treatment, etc., and achieve the effect of removing chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

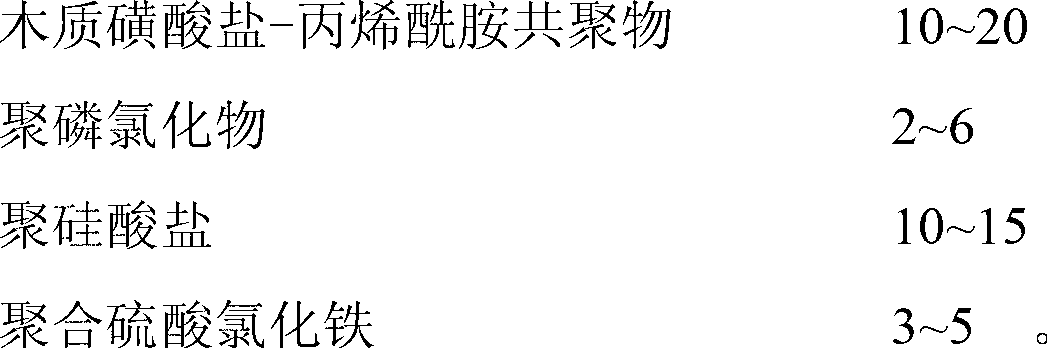

[0017] A slaughter wastewater flocculant, consisting of the following components in parts by mass:

[0018]

[0019] In the present embodiment, polyphosphorus chloride is polyphosphorus ferric chloride;

[0020] In this embodiment, the polysilicate is aluminum polysilicate.

[0021] Under the condition of room temperature, the above components are fully mixed, stirred for 30-150 minutes and left standing overnight to obtain the flocculant provided by the present invention.

[0022] The flocculant in this example has a removal rate of more than 95% for grease and SS, a removal rate of more than 96% for chroma, and a removal rate of more than 90% for COD.

Embodiment 2

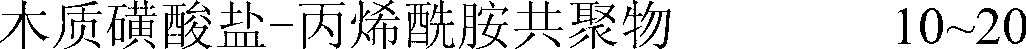

[0024] A slaughter wastewater flocculant, consisting of the following components in parts by mass:

[0025]

[0026] In this embodiment, polyphosphorus chloride is polyphosphorus aluminum chloride;

[0027] In this embodiment, the polysilicate is iron polysilicate.

[0028] Under the condition of room temperature, the above components are fully mixed, stirred for 30-150 minutes and left standing overnight to obtain the flocculant provided by the present invention.

[0029] The flocculant in this example has a removal rate of more than 95% for grease and SS, a removal rate of more than 96% for chroma, and a removal rate of more than 90% for COD.

Embodiment 3

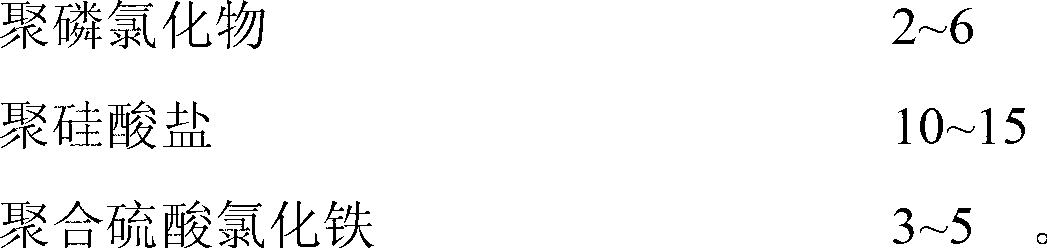

[0031] A slaughter wastewater flocculant, consisting of the following components in parts by mass:

[0032]

[0033] In this embodiment, polyphosphorus chloride is polyphosphorus aluminum chloride;

[0034] In this embodiment, the polysilicate is aluminum polysilicate.

[0035] Under the condition of room temperature, the above components are fully mixed, stirred for 30-150 minutes and left standing overnight to obtain the flocculant provided by the present invention.

[0036] The flocculant in this example has a removal rate of more than 95% for grease and SS, a removal rate of more than 96% for chroma, and a removal rate of more than 90% for COD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com