Yarn Cutting Suction Device and Spinning Winding Device

The technology of a suction device and a winding device is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

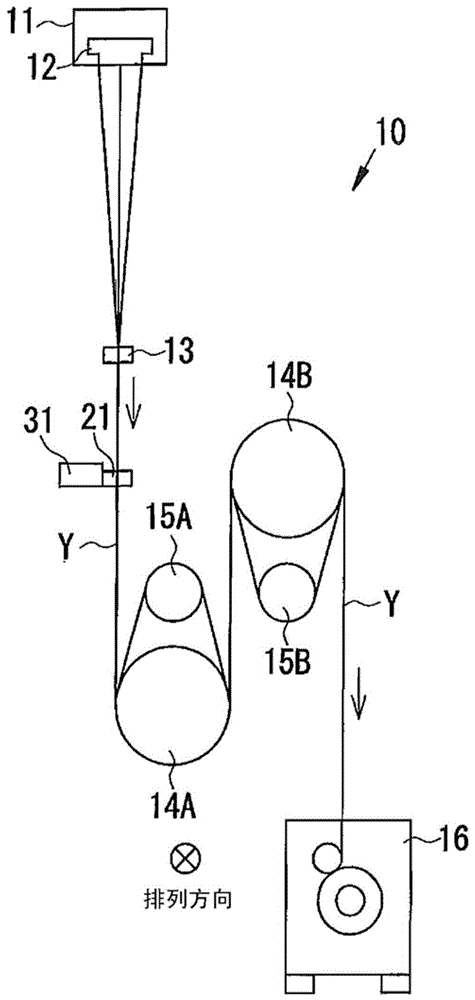

[0032] use Figure 1 to Figure 6 The spinning winding device 10 of Example 1 of the present invention will be described. Such as figure 1 As shown, the spinning and winding device 10 mainly includes a spinning device 11, an oil supply nozzle 13, a yarn path restricting guide 21, a yarn cutting and sucking device 31, godet rollers 14A, 14B, a yarn winding device 16, and a control unit 18. . The fiber spun by the spinning device 11 travels toward the yarn winding device 16, undergoes various processes on the way to form a yarn Y, and is wound up as a package. In the following description, fibers and threads are not distinguished, and they are only described as threads. Further, the upstream side and the downstream side in the direction in which the fiber (yarn Y) travels from the spinning device 11 to the yarn winding device 16 will be described as the upstream side and the downstream side in the traveling direction of the yarn Y, respectively.

[0033] The spinning device 1...

Embodiment 2

[0063] then use Figure 7 to Figure 11 The spinning winding device 10 of Example 2 of the present invention will be described. Embodiment 2 is similar to Embodiment 2 in that the suction part 44 of the thread cutting suction device 31 and the first cutter 61 are fixed, and that the plurality of threads Y are moved to the side of the first cutter 61 by the wire pulling guide 60 . 1 is quite different from the thread cutting suction device 31. Since the configuration other than the thread cutting and suction device 31 is the same as that of the first embodiment, the thread cutting and suction device 31 will be mainly described.

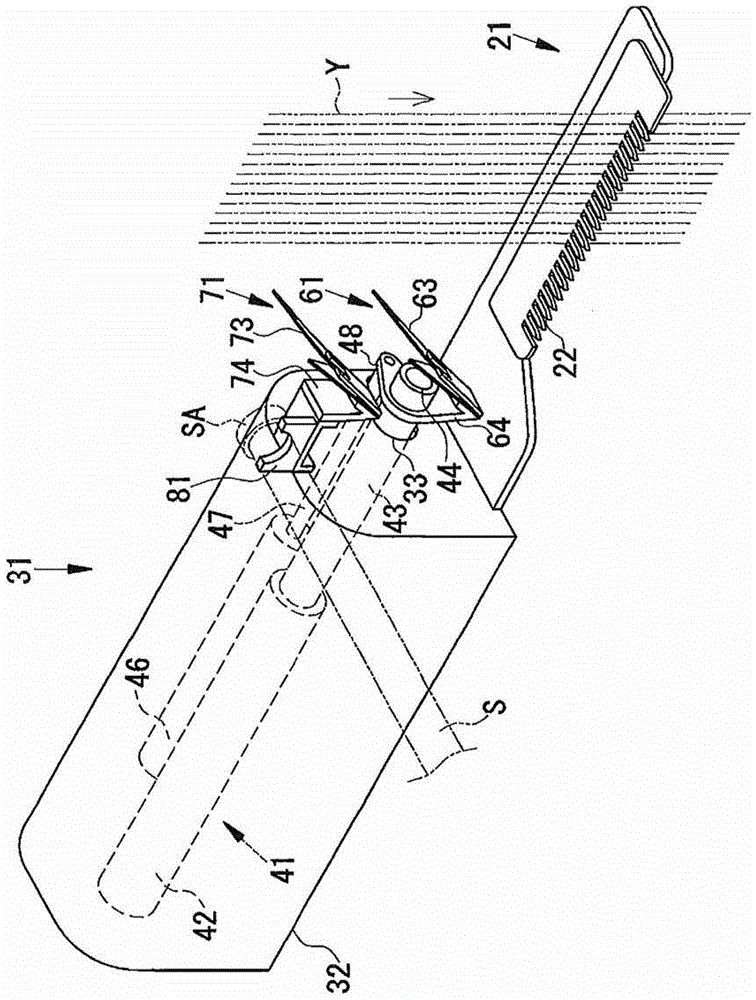

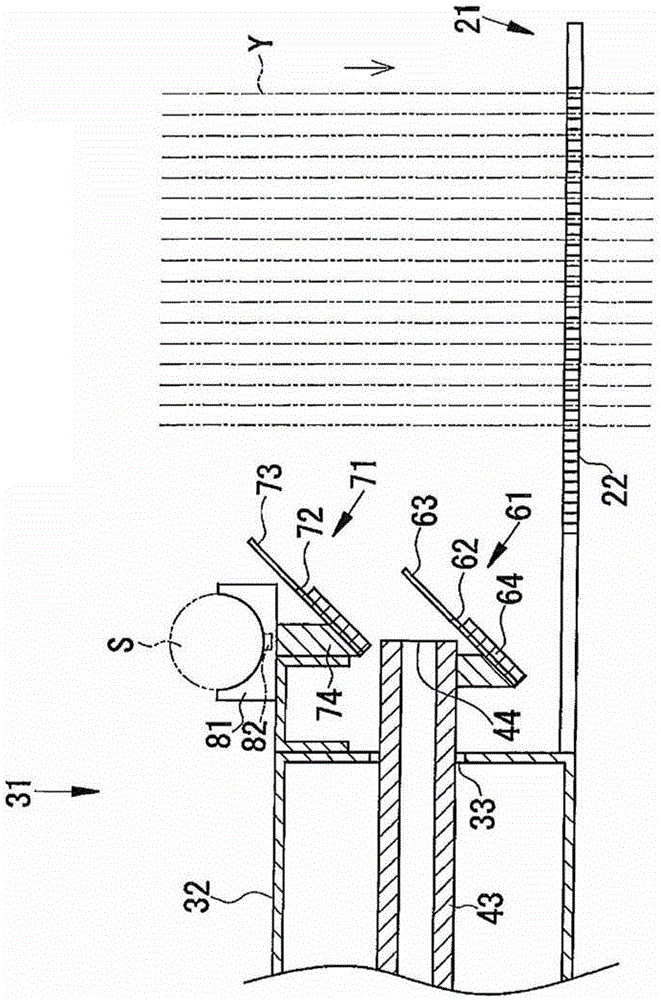

[0064] Such as Figure 7 , Figure 8 , Figure 9 As shown, the thread cutting suction device 31 mainly includes a suction device 41 , a wire pulling guide 91 , a first cutter 61 , a second cutter 71 , and a positioning unit 81 .

[0065] The suction device 41 is a device that suctions the plurality of yarns Y cut by the first cutter 61 . The sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com