Installation method for anti-side-rolling twisted rod seat of rail car

An anti-roll torsion bar and installation method technology, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, can solve problems such as poor stress conditions, and achieve convenient and fast installation, reduce self-weight, and reduce welding. The effect of seam fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

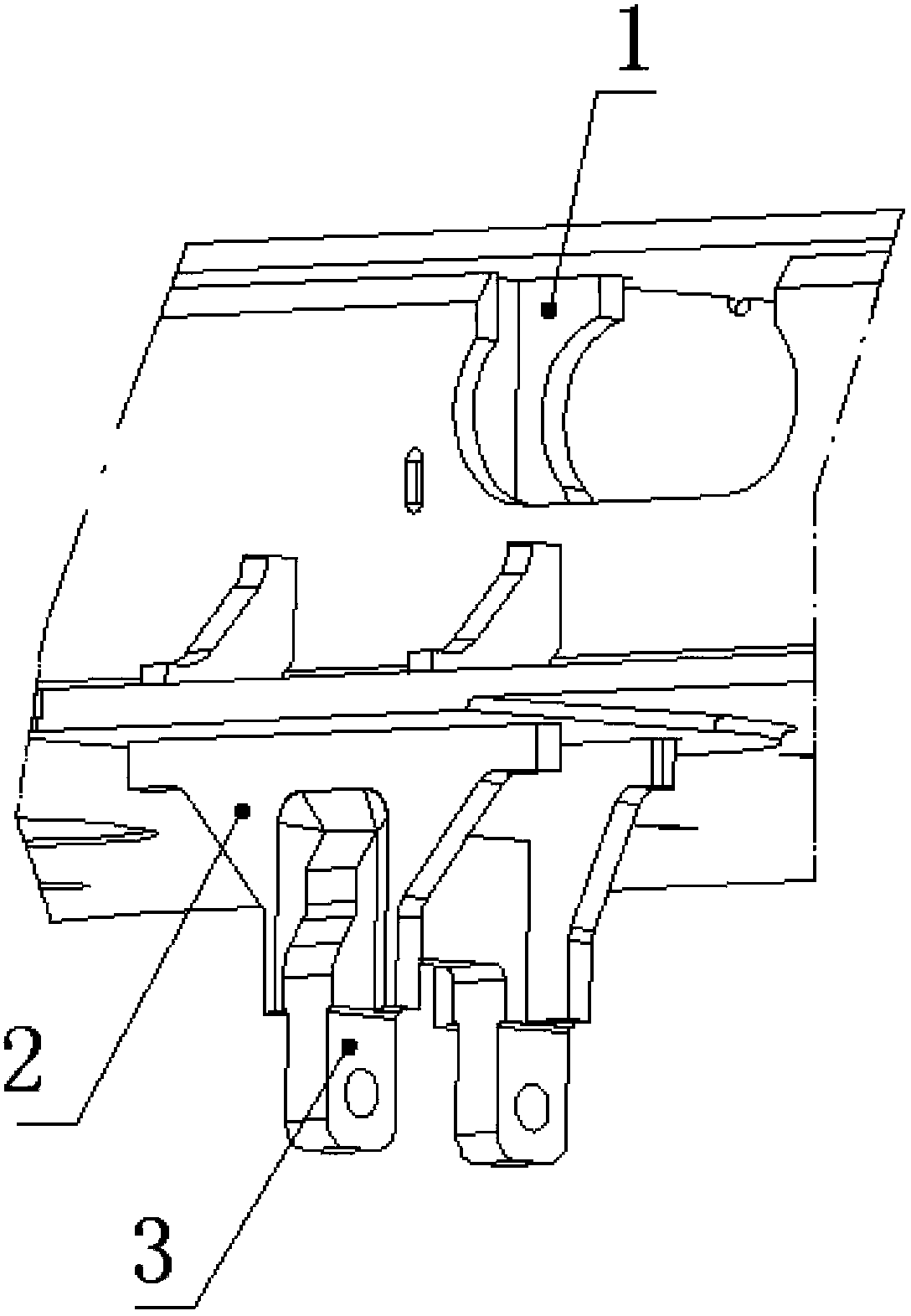

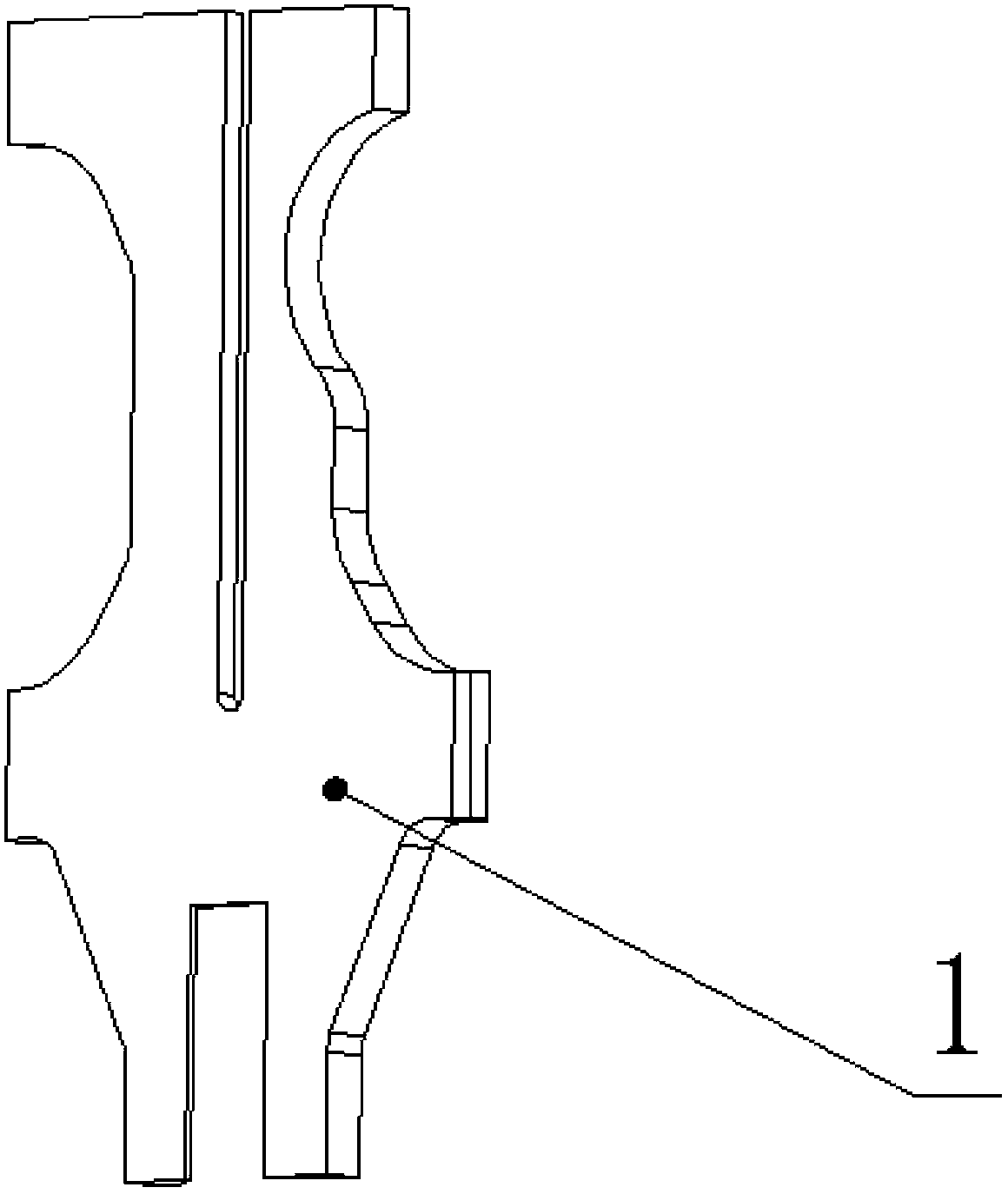

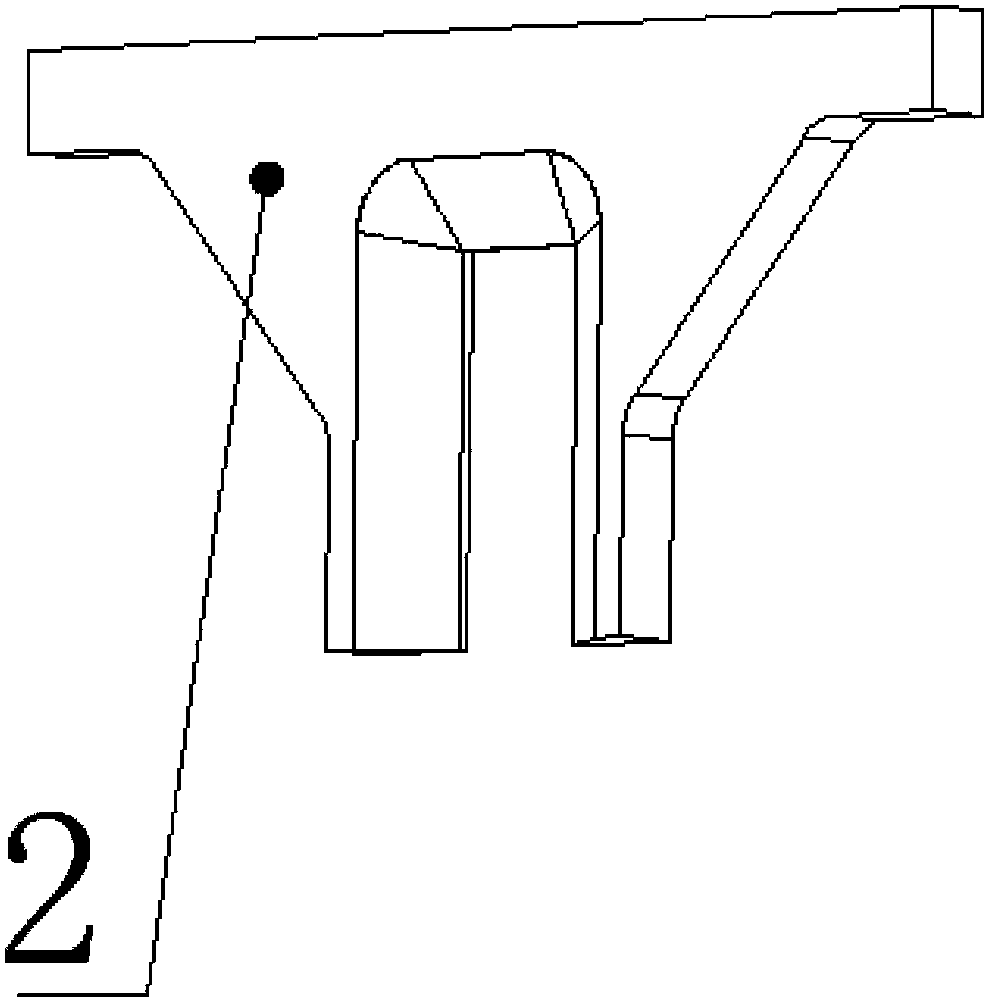

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the anti-rolling torsion rod seat involved in the method embodiment of the present invention is composed of a first web 1, a second web 2, and an anti-rolling torsion rod mounting block 3. The bottom center of the anti-rolling torsion rod mounting block 3 There are notches, and two sides of the notches are provided with mounting holes for the anti-side-rolling torsion bar; the installation method includes the following steps:

[0020] In the first step, a hole through which the first web 1 passes is opened on the lower cover plate 5 of the corbel;

[0021] The second step is to insert the first web 1 from the hole, and insert the upper part of the first web 1 with the inner baffle 6 of the corbel through the upper slot with the opening facing upward;

[0022] The third step, the upper end of the first web 1 is welded to the lower end surface of the upper cover plate 5 of the corbel, the upper slot of the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com