Implementation method of selective laser sintering (SLS) technology and fiber implantation device

A technology of laser sintering and implementation method, which is applied in processing and manufacturing, additive processing, solid material additive processing, etc., can solve the problems of low strength impact strength, low strength, and low strength of molded parts, and achieve fiber aspect ratio Improvement, high-strength use requirements, and the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

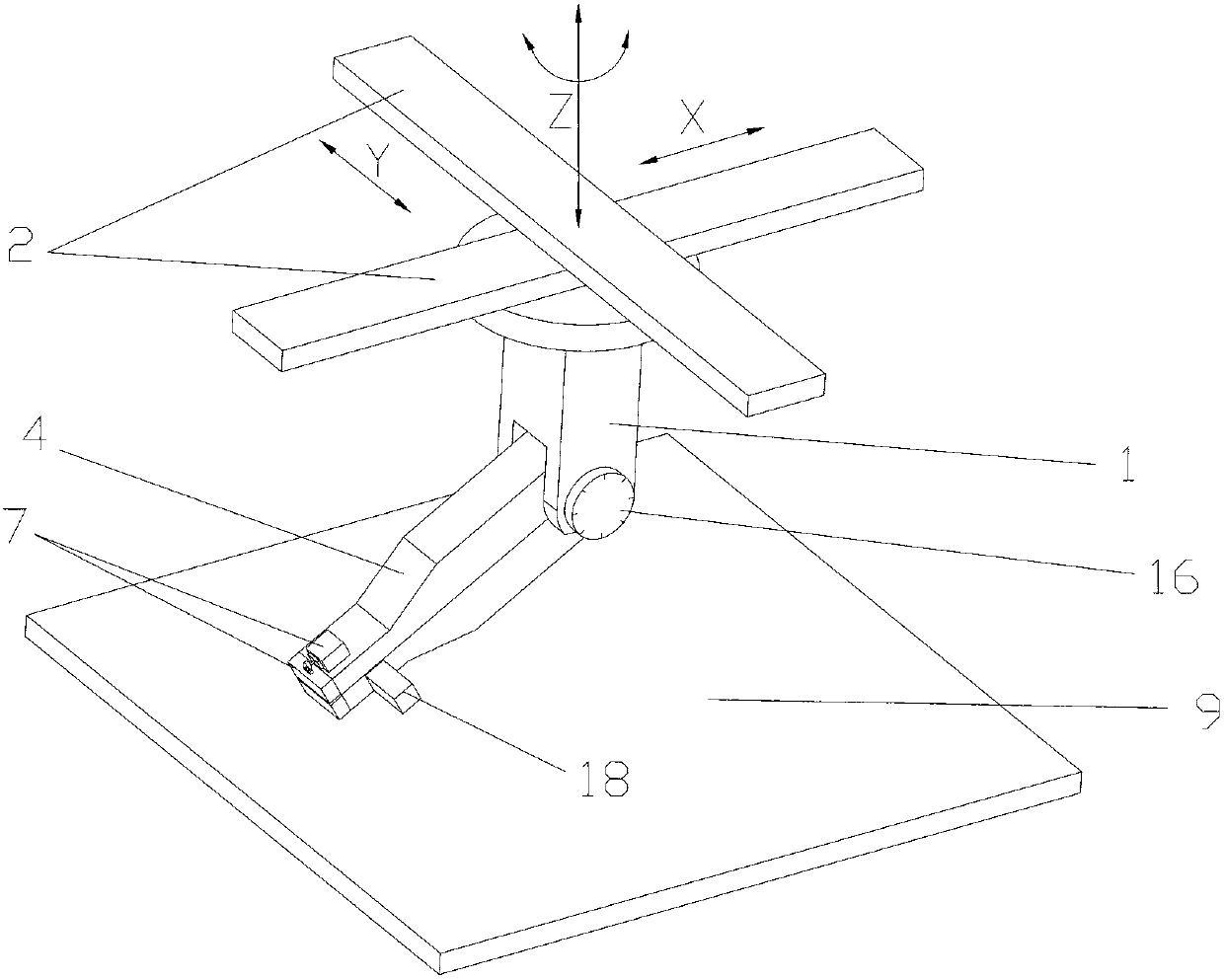

[0044] see figure 1 , the fiber implantation device of the present invention is mainly composed of a base 1 arranged on a slide rail 2 and a fiber conveyor 4 connected to the base 1, wherein,

[0045] see figure 1 , the slide rail 2 is a motion mechanism with four degrees of freedom, the four degrees of freedom are linear motion along the X-axis, Y-axis and Z-axis direction and rotation around the Z-axis, each movement is controlled by a separate Driven by stepper motors, these stepper motors are controlled by the control system, so that the base 1 connected to the slide rail 2 realizes movement in the X-axis, Y-axis and Z-axis directions and rotation around the Z-axis; the specific implementation method can be Refer to the slide rail mechanism of the worktable in the CNC machining center.

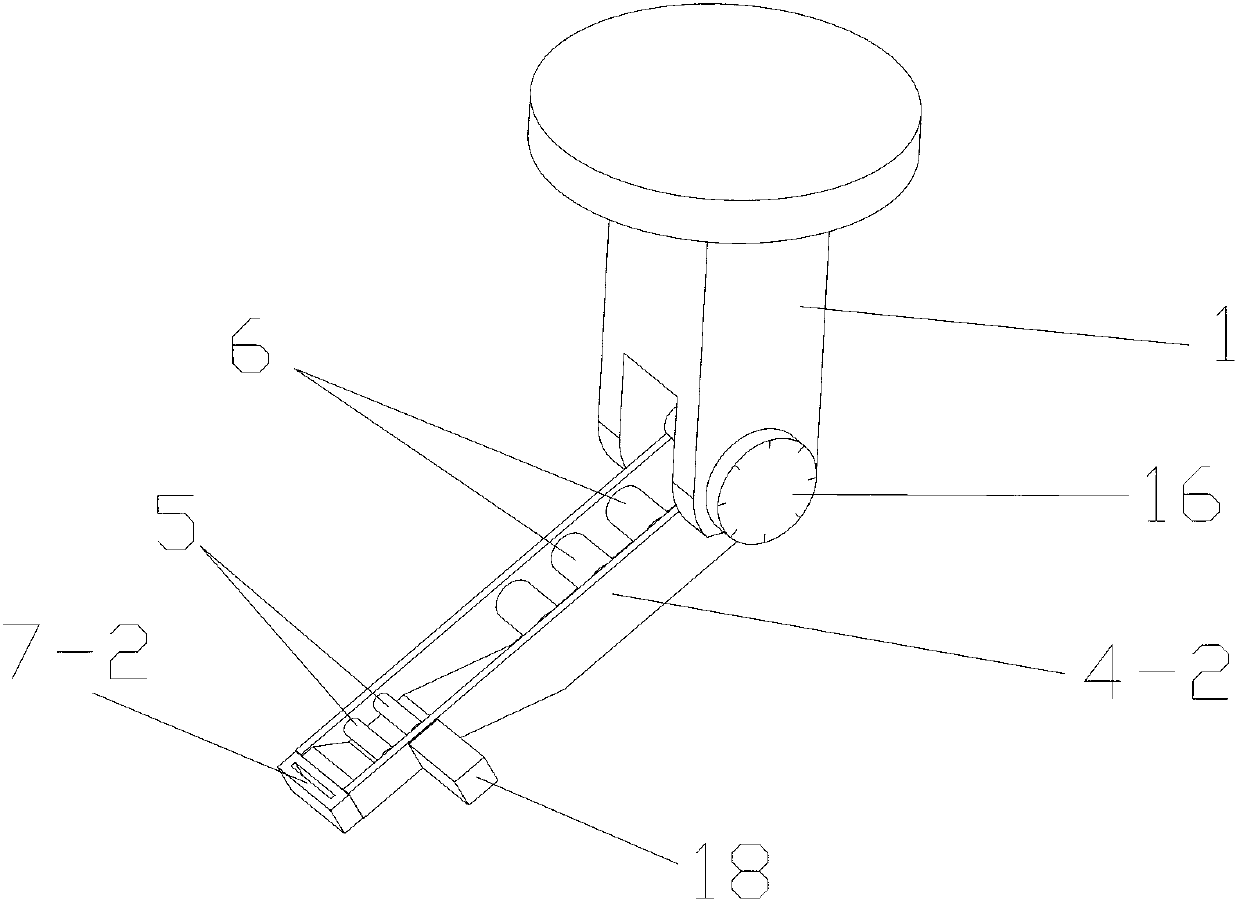

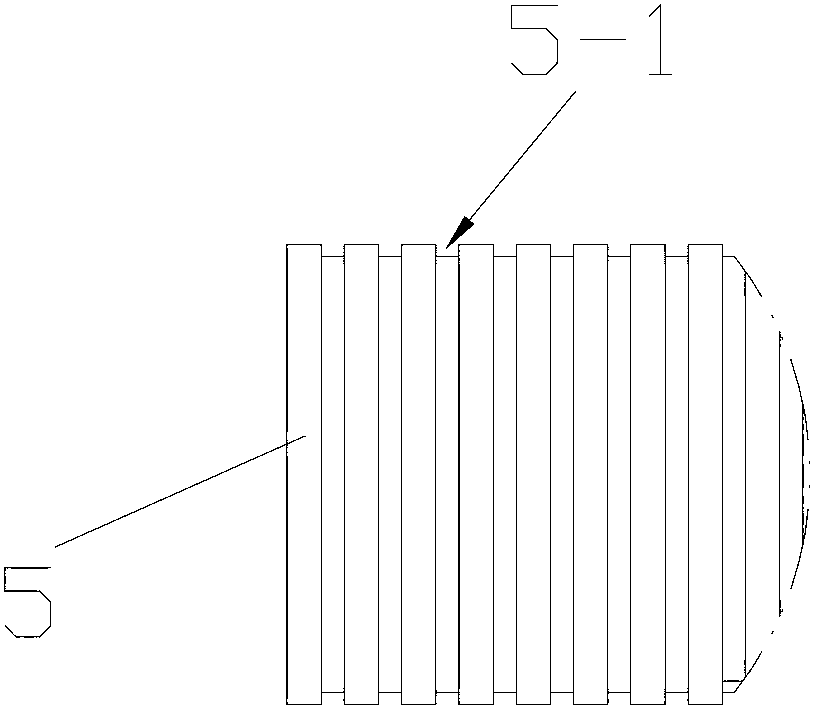

[0046] see Figure 1-7, the fiber conveyor 4 is mainly composed of a bracket, a traction roller group, an auxiliary roller group and a cutting mechanism 7, wherein the bracket is a casi...

Embodiment approach

[0049] see Figure 8 , Figure 9 with Figure 10 , the implementation method of selective laser sintering process of the present invention, comprises the following steps:

[0050] (1) The working cylinder 11 is lowered by a certain distance, and the powder supply cylinder 12 is raised by a certain distance, and the powder spreading device 13 spreads a single layer or multiple layers of sintered powder material 14 on the sintering working plane 9 to form a bottom layer of sintered powder material 14-1 ;

[0051] (2) Lay a fiber layer on the bottom sintered powder material layer 14-1 by using a fiber implantation device, the laying process is as follows:

[0052] (2.1) The slide rail 2 in the fiber implantation device moves the fiber conveyor 4 to the target position under the control of the control system; the fiber conveyor 4 simultaneously outputs a plurality of continuous long fiber filaments 8 in parallel, 8, the fiber conveyor 4 moves back, so that these output fiber f...

Embodiment 2

[0061] see Figure 9 , In this embodiment, two sets of fiber implantation devices are used, and the fiber conveyors 4 in the two sets of fiber implantation devices are arranged obliquely opposite to each other, and the fiber filaments 8 output by the two intersect each other. In the two fiber implantation devices, an angle adjustment motor 17 is provided at the connecting joint between the support in the fiber conveyor 4 and the base 1, and the angle adjustment motor 17 is a stepping motor controlled by a control system, thereby realizing Automatic adjustment of the inclination angle of the stand. Other implementations of the fiber implantation device of this embodiment are the same as those of Embodiment 1.

[0062] see Figure 9 with Figure 10 , the implementation method of the selective laser sintering process of this embodiment is realized by using the above two sets of fiber implantation devices, and its difference from the implementation method of Example 1 is:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com