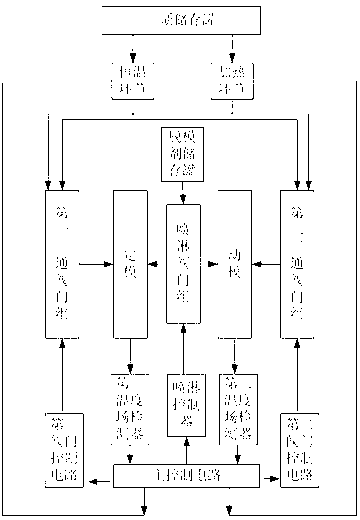

Automatic adjustment and control device for mold temperature field

An automatic adjustment and mold temperature technology, applied in the field of electromechanical measurement and control, can solve the quality problems of finished products, the inability to ensure that the mold temperature field is consistent with the die-casting process, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

[0022] The general mold use is divided into: feeding - die casting - demoulding - cooling - feeding, so several steps and continuous cycle.

[0023] Such as figure 1 As shown, when the mold temperature field automatic adjustment control device of the present invention starts to work, it first performs a cold start. During the cold start, the electric heater in the heating link quickly heats the working medium oil from the working medium storage tank, and heats the heated...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap