Heat-recovery thermostatic bath circulating device and constant temperature method thereof

A heat recovery and recycling equipment technology, applied in heating or cooling equipment, chemical instruments and methods, laboratory utensils, etc., to achieve high temperature control accuracy, reduce testing costs, and reduce power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

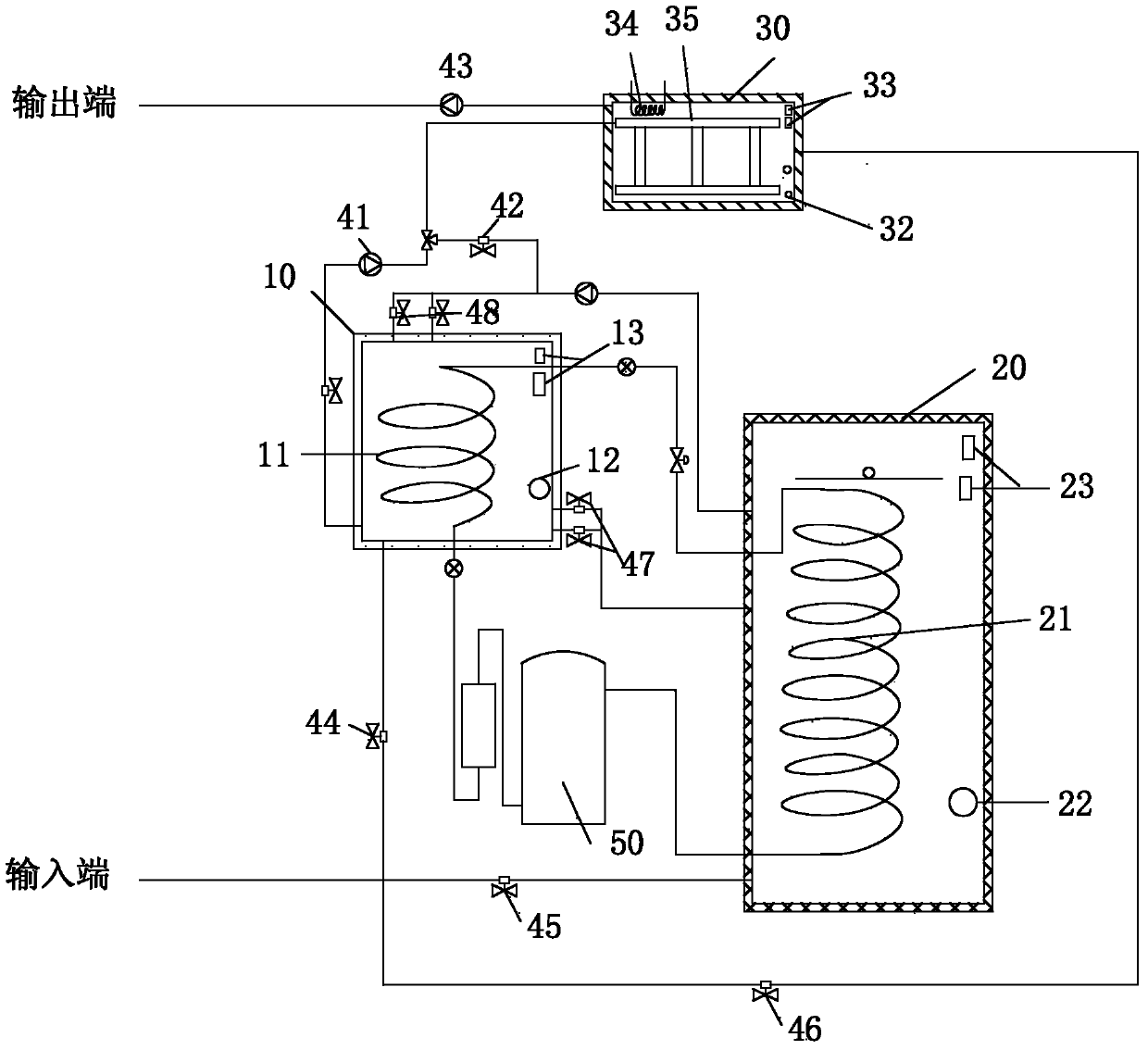

[0049] The heat recovery type constant temperature tank circulation equipment of this embodiment can be used as a constant temperature source in an electrical performance laboratory, providing a stable temperature environment for performance tests of refrigeration appliances and heat exchangers. Its structure is as figure 1 As shown, the equipment is provided with an output terminal and an input terminal respectively connected to the user terminal, and the equipment includes a cold solution tank 10 , a hot solution tank 20 , a constant temperature solution tank 30 , and a compressor 50 . The inside of the cold solution tank 10 is provided with a refrigeration coil one 11 , a temperature sensor one 12 and a liquid level sensor one 13 . The inside of the hot solution tank 20 is provided with a heating coil 21 , a temperature sensor 22 and a liquid level sensor 23 . The constant temperature solution box 30 is provided with a heating device 34 and a temperature sensor 3 32 .

[...

Embodiment 2

[0070] The structure of the equipment of this embodiment is as Figure 6 As shown, the difference with Embodiment 1 is that: the constant temperature solution tank 30 of the equipment in this embodiment is also provided with a refrigeration coil 2 31; the compressor 50, the heating coil 21 and the refrigeration coil 2 31 are sequentially connected to form Refrigerant cycle two.

[0071] There are a large number of temperature measuring devices in the small electrical performance laboratory, such as thermocouples, platinum resistance, etc. In order to ensure the accuracy of the test results and maintain the control accuracy of the ambient temperature, the temperature measuring device needs to be verified before use, and needs to be calibrated after a period of use. The equipment in this embodiment can also be used as a constant temperature bath to check the temperature measuring device. The specific method is: the compressor 50, the heating coil 21 and the second refrigeratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com