Method for welding copper alloy and aluminum matrix composite

An aluminum-based composite material and copper alloy technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of metal burning and interface reaction, improve weld formation, increase welding temperature and holding time, weaken burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

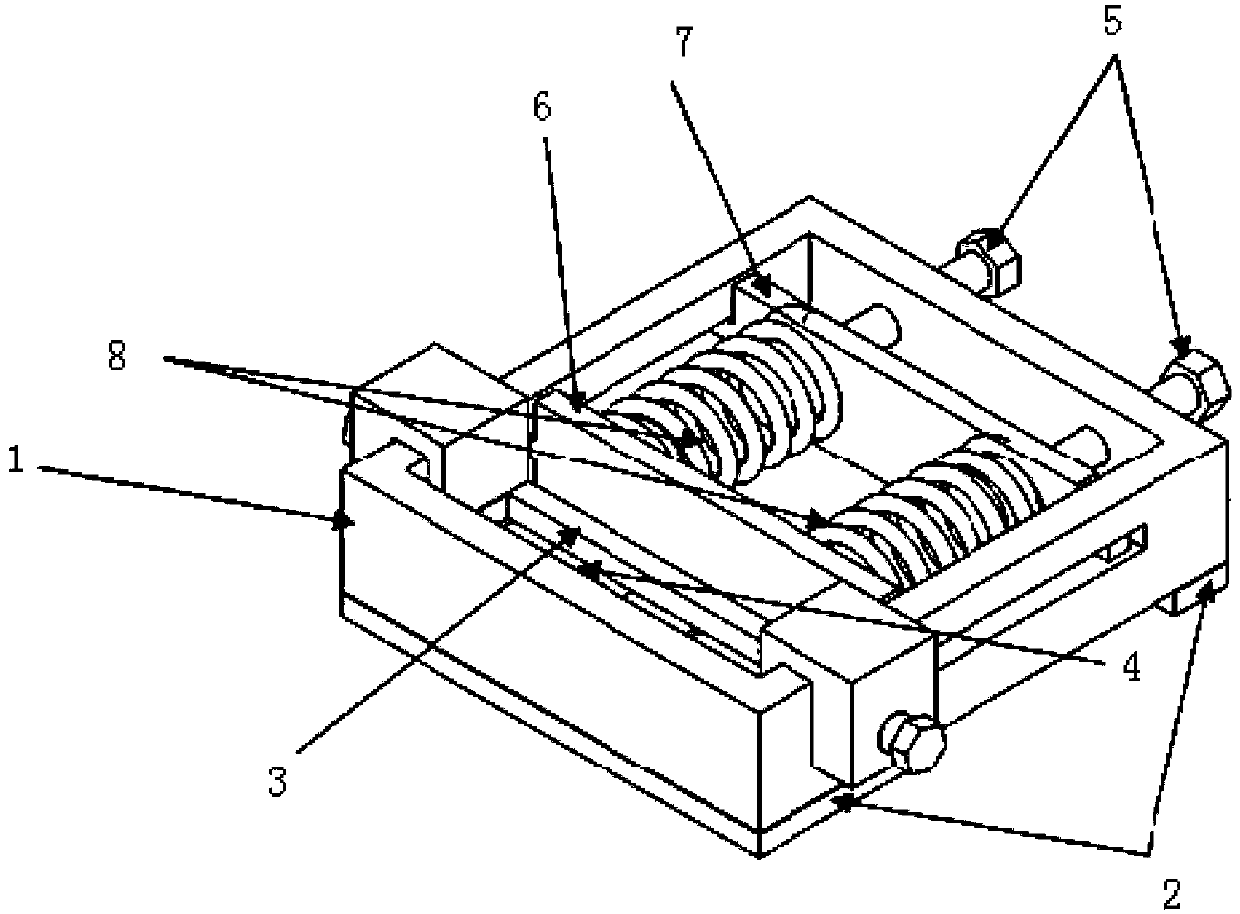

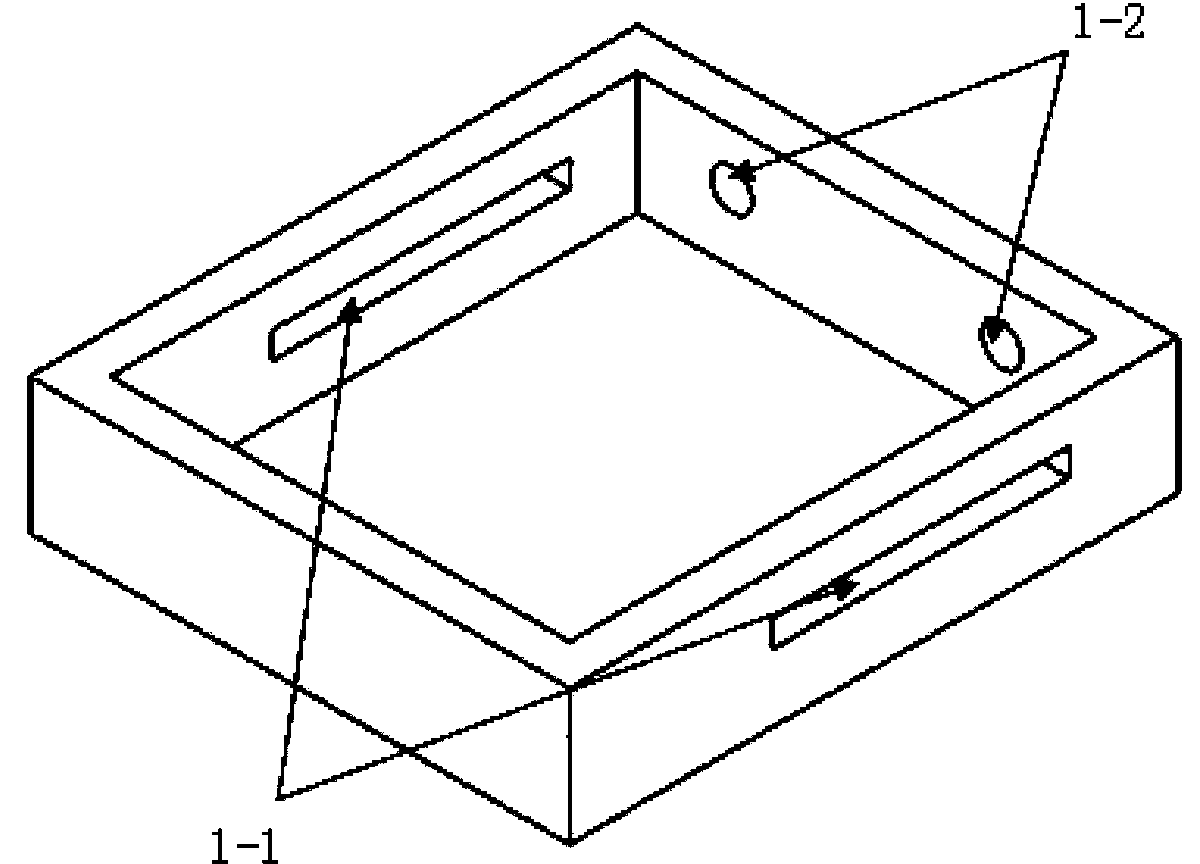

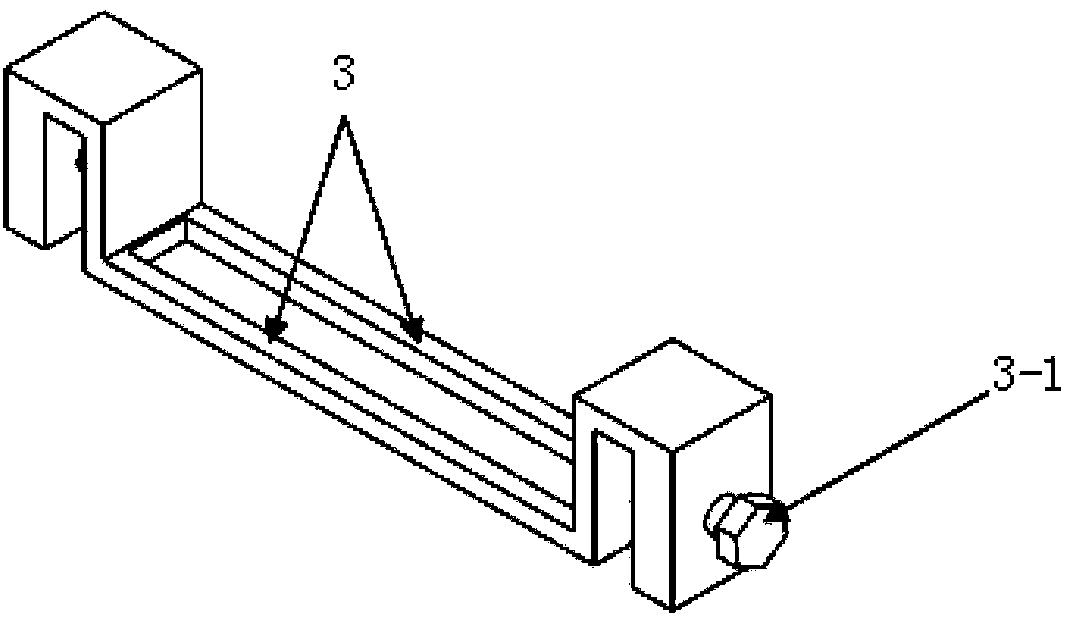

[0021] Embodiment 1: A method for welding copper alloys and aluminum-based composite materials in this embodiment is implemented in the following steps:

[0022] 1. Pretreatment of copper alloy and aluminum matrix composite to be welded;

[0023] 2. Put the copper alloy and the aluminum-based composite material into the welding fixture, adjust the relative position of the copper alloy and the aluminum-based composite material, and apply a contact pressure of 1 to 5 MPa on the contact surface; wherein, the copper alloy and the aluminum-based composite material The relative position of the copper alloy and the aluminum matrix composite material is that the wrong side of the butt joint surface is 0-0.2mm, and the gap between the butt joint surfaces is 0-0.1mm;

[0024] 3. Put the fixed copper alloy and aluminum matrix composite material into the vacuum chamber, and then evacuate to a vacuum degree of 5×10 -4 Pa~5×10 -2 Pa;

[0025] 4. Then use the upper defocus mode to hit the...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that the pretreatment method in step 1 is to perform mechanical grinding and chemical cleaning on the butt joint surface of the copper alloy and the aluminum-based composite material to be welded and its vicinity. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aluminum-based composite material described in step 1 is a particle-reinforced aluminum-based composite material consisting of two parts: a 2A12 aluminum matrix and a SiC ceramic particle-reinforced phase, wherein , wherein the composition of the 2A12 aluminum matrix is Cu: 4.4%, Mg: 1.5%, Mn: 0.6%, impurity ≤ 0.15%, and the balance is Al. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com