Large ammonification high pressure spherical stirring reaction kettle

A technology of stirring reaction kettle and ammoniation, which is applied in chemical/physical/physical-chemical stationary reactors, pressure vessels used in chemical processes, etc., can solve the problem that the pressure of the reaction kettle is not easy to control, the adverse effects of the ammoniation reaction, and the easy occurrence of safety. Accidents and other problems, the control of the reaction rate is easier to achieve, the force distribution is good, and the rapid cooling is better.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below by specific embodiment in conjunction with accompanying drawing the present invention will be described in further detail:

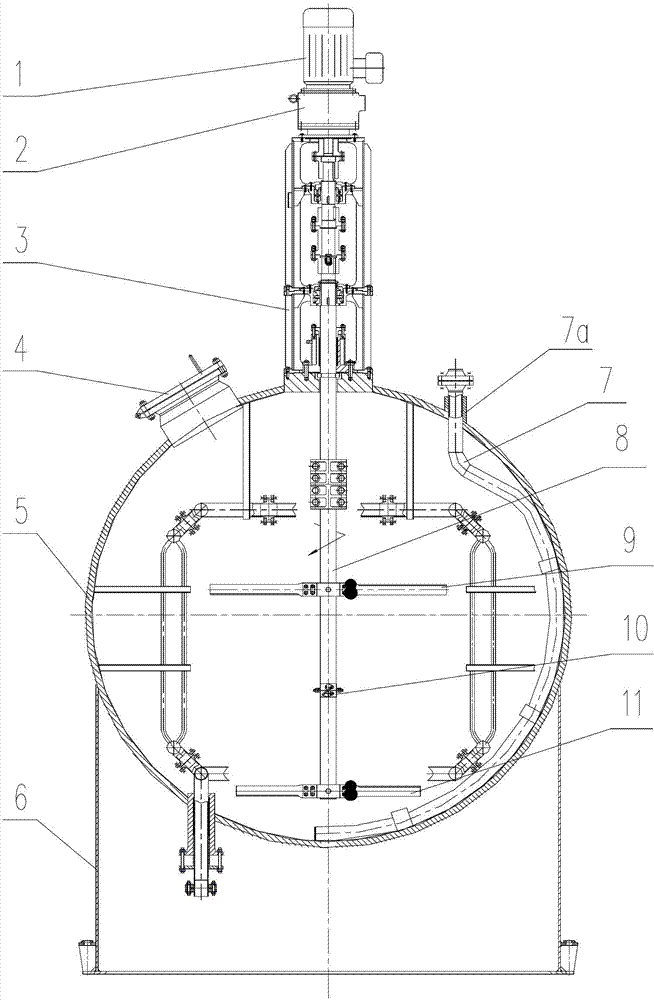

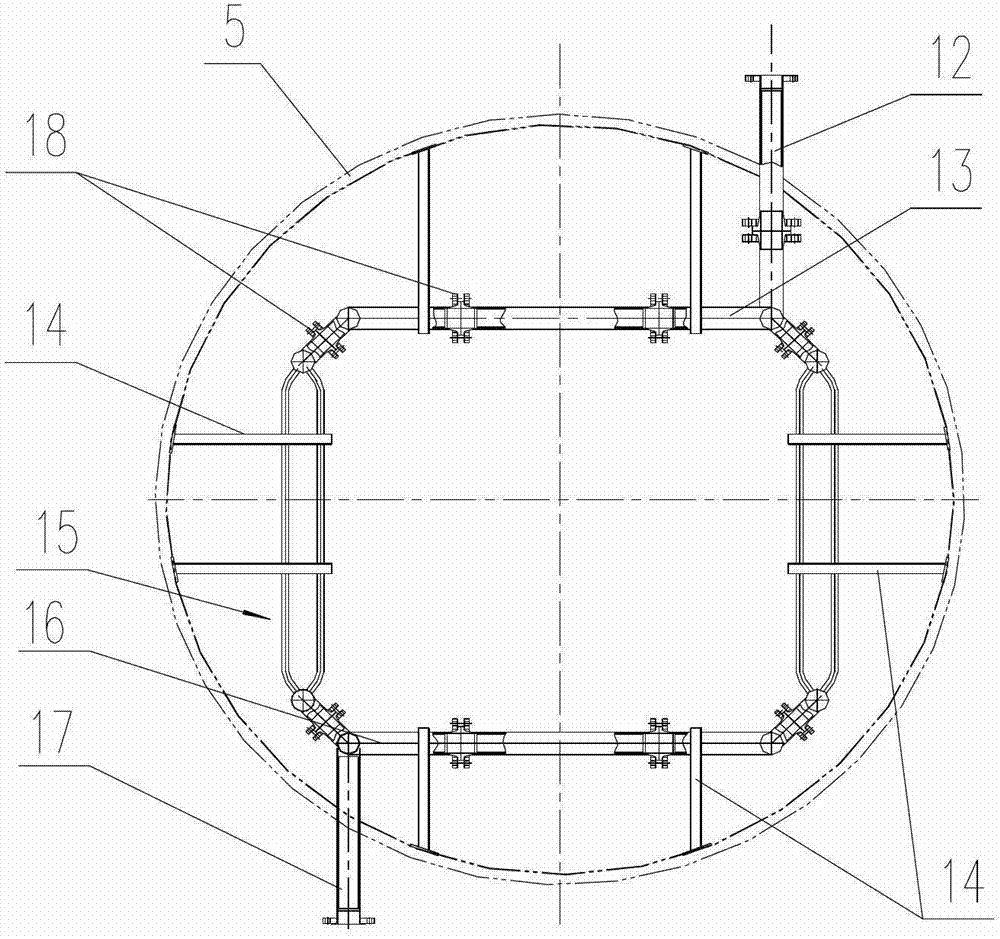

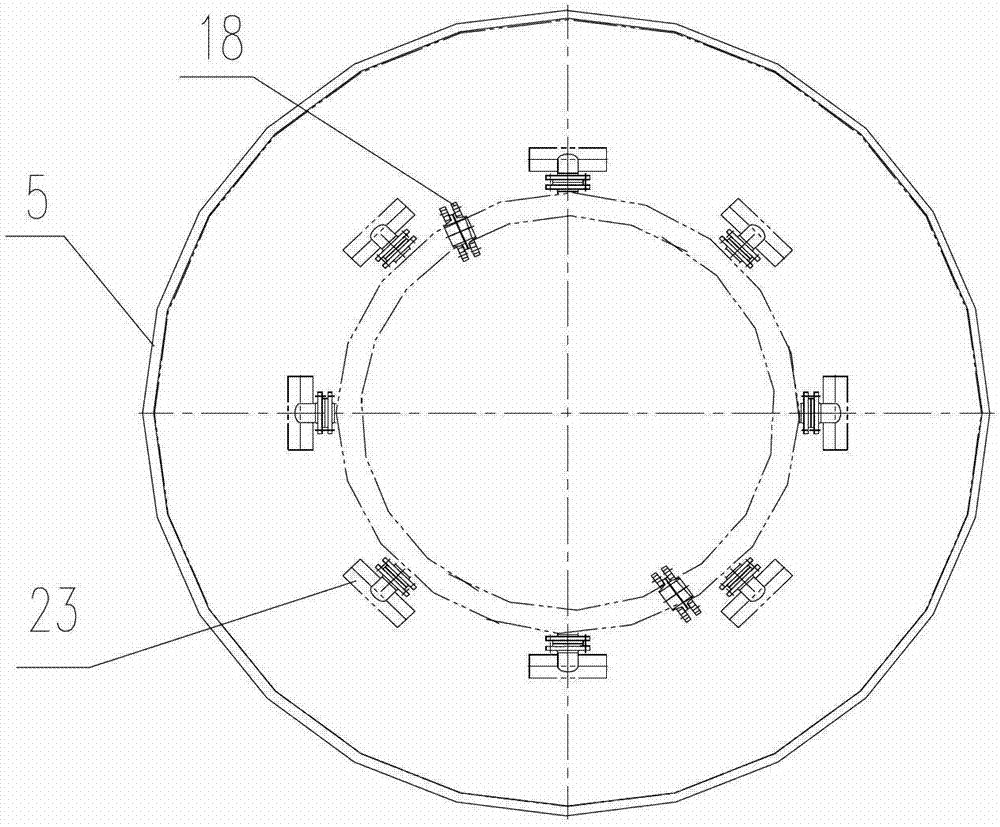

[0032] see figure 1 , The high-pressure spherical stirred reactor is composed of a kettle body 5, a skirt 6, a stirring device 3, a heat exchange device and a discharge pipe 7.

[0033] Such as figure 1 As shown, the kettle body 5 is welded by two hemispherical heads, and there is only one butt weld in the middle. The upper part of the kettle body 5 is provided with a feeding port (the feeding port is not shown in the accompanying drawings), a discharge nozzle 7a and a human body. Hole 4, kettle body 5 bottom is supported with skirt seat 6.

[0034] The stirring device 3 is arranged on the upper end of the kettle body 5 and the two are sealed and matched. The upper end of the stirring device 3 is connected with the reducer 2 and the motor 1 in sequence, and the stirring shaft 8 of the stirring device 3 penetrates into the kettle body 5; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com