Method and device for collaborative removal of mercury in flue gas

A collaborative removal device and wet flue gas desulfurization technology, which is applied in the fields of desulfurization flue gas collaborative demercury removal, dust collector, and denitrification, can solve the problems of unsatisfactory mercury concentration, difficult follow-up treatment, and failure to use mercury removal functions, etc. problem, to achieve the effect of meeting mercury emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

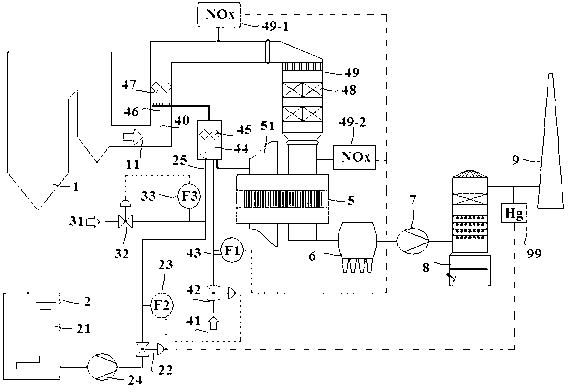

[0044] like figure 1 , 2 As shown, the mercury removal oxidant uses 0-43% Wt. ammonium chloride solution.

[0045] The flue gas 11 generated by the combustion of the boiler 1 flows through the upstream flue 40 of the SCR denitrification device, mixes with the mercury removal oxidant HCl gas sprayed by the AIG injection pipe 46 of the SCR denitrification device, and after being uniformly mixed by the flue gas mixer 47, enters the SCR denitrification device Reactor 49, under the action of SCR catalyst 48, the gaseous elemental mercury Hg in the flue gas 0 Oxidized to gaseous divalent mercury oxide Hg 2+ (HgCl 2 ); the flue gas passes through the air preheater 5 for heat exchange and then enters the dust collector 6 downstream, and the particulate mercury Hg (p) in the flue gas is collected and removed by the dust collector 6; Entering the wet flue gas desulfurization (WFGD) device 8, the gaseous divalent mercury oxide Hg in the flue gas 2+ Absorbed by the spray liquid of t...

Embodiment 2

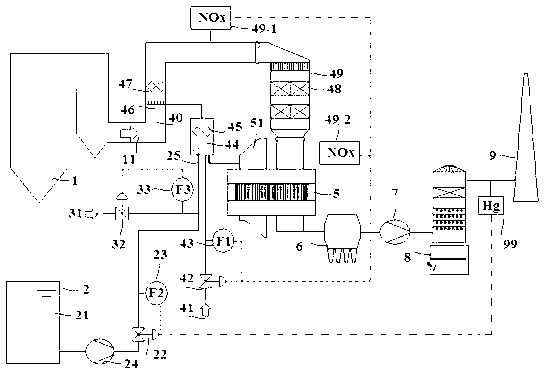

[0053] as attached image 3 Shown: 0-37% Wt. hydrochloric acid solution is used as the mercury removal oxidant.

[0054] This embodiment is basically the same as the embodiment, and the difference is that in addition to ammonium chloride solution, an oxidant similar to ammonium chloride that can be decomposed by heat to generate HCl can also be used as the mercury removal oxidant, and it is also easy to think of directly using hydrochloric acid solution. The hydrochloric acid solution is used as the mercury removal oxidant, and the only control strategy is different from the ammonium chloride oxidant. SCR denitrification control and mercury removal control are two separate closed-loop circuits, and the opening degree signal of the flow regulating valve 22 of the hydrochloric acid solution of the mercury removal oxidant does not need to be fed back to the flow regulating valve 42 of the SCR denitrification reducing agent to adjust the flow rate 43 of the denitration reducing ag...

Embodiment 3

[0057] On the basis of Examples 1 and 2, the mercury emission concentration and denitrification efficiency can be controlled by simultaneously adjusting the concentration and / or amount of the mercury removal oxidant solution.

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com