Air-flowing type dried tobacco water control method

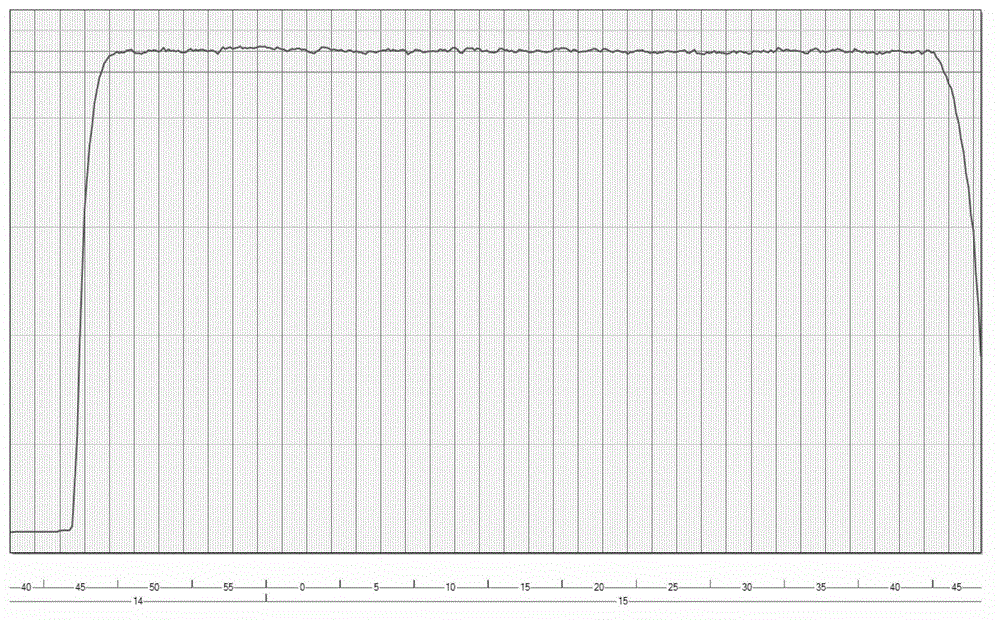

A control method and air-flow technology, which is applied in the preparation of tobacco, tobacco, food science, etc., can solve problems such as instability, time-lag fluctuation, and time delay, and achieve good control, product quality assurance, and timely correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

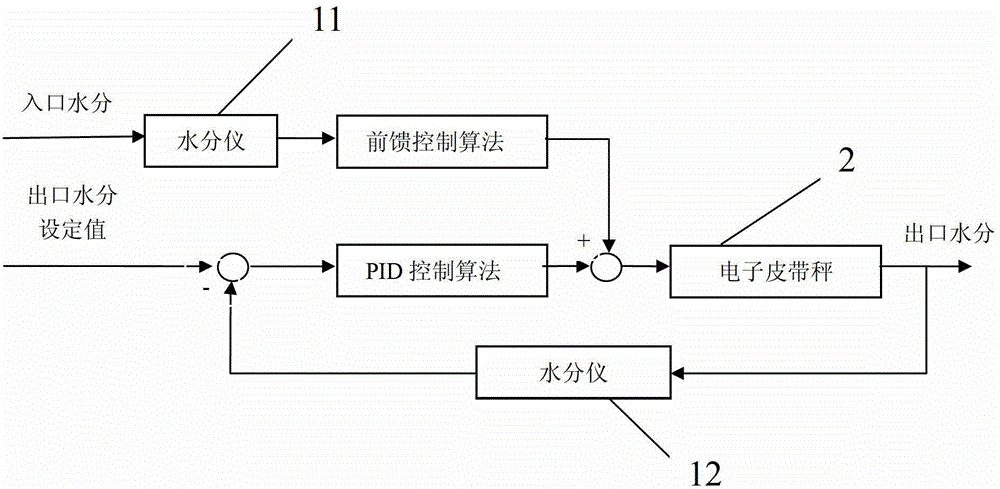

[0022] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

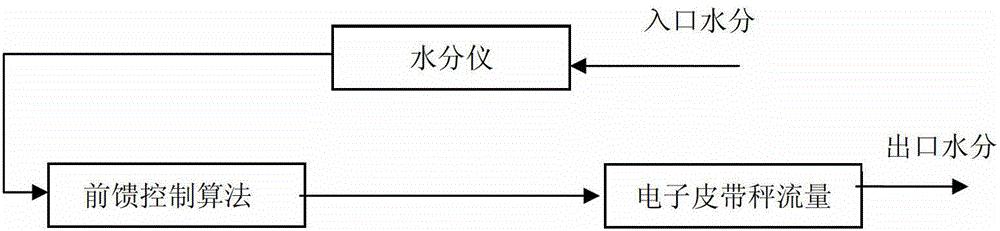

[0023] see figure 2 , which shows a method for controlling the moisture content of air-dried silk according to the present invention, the control method comprising the following steps:

[0024] Measure the moisture at the inlet of the airflow dryer through the moisture meter 11 installed at the inlet of the airflow dryer, and use the feedforward control algorithm to obtain the first parameter for adjusting the flow rate of the cut tobacco at the inlet, and then send the first parameter to the electronic belt scale 2; Measure the moisture at the outlet of the airflow dryer through the moisture meter 12 arranged at the outlet of the airflow dryer, and use the result measured by the moisture meter and the set value of the outlet moisture to obtain the first step for adjusting the flow of shredded tobacco at the inlet thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com