Method for rapidly detecting zinc content of solution

A solution and rapid technology, applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc., can solve the problems of inability to meet process requirements, long detection time, and long detection time consumption, etc. problem, achieve the effect of saving natural cooling time, short detection time and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

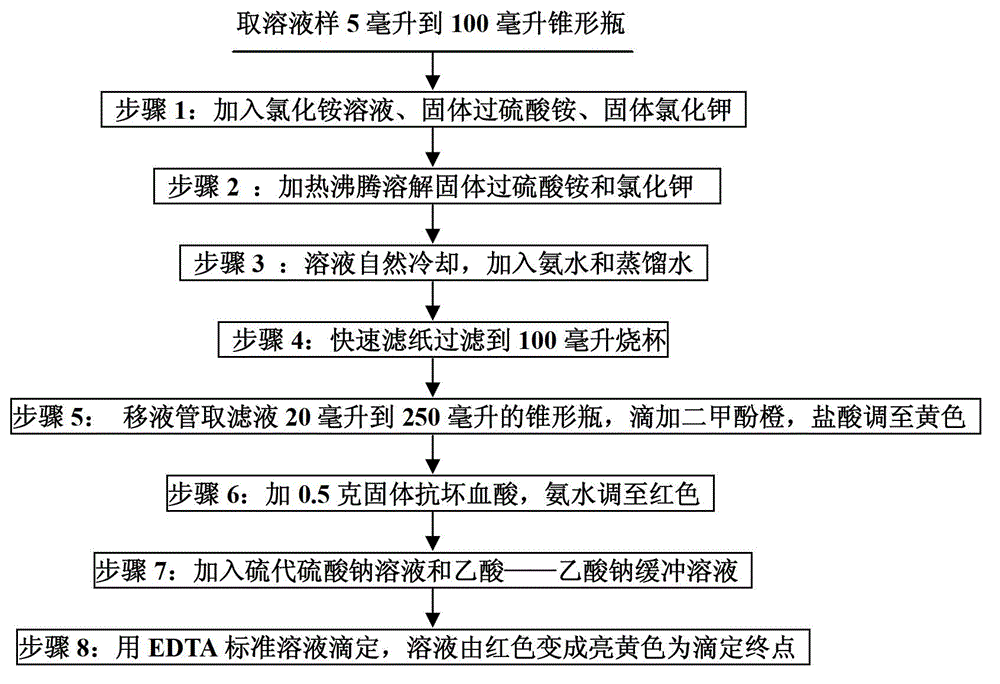

Image

Examples

no. 1 example

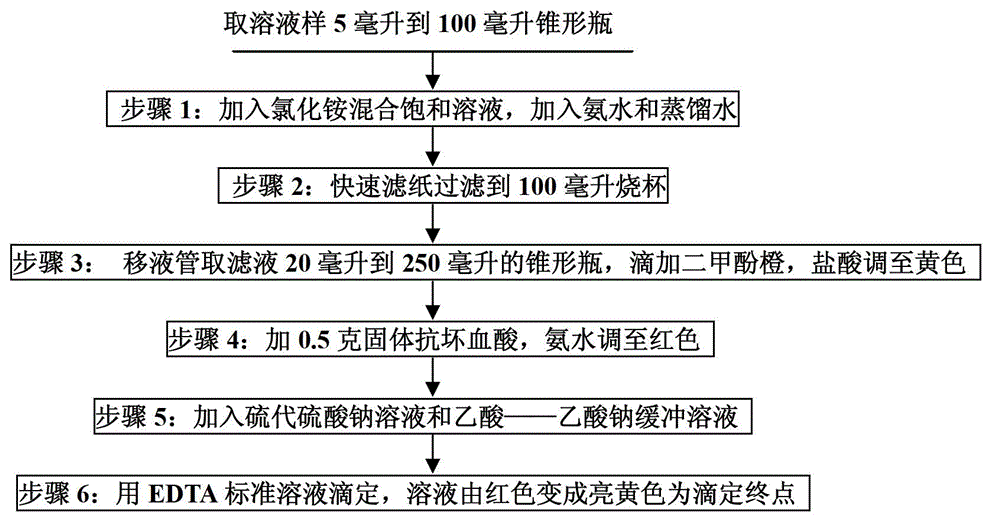

[0027] This embodiment is the first example of the method for rapid detection of zinc content in solution according to the present invention, comprising the steps of:

[0028] (1), take neutral leaching supernatant solution sample 5 milliliters to 100 milliliter volumetric flasks, and add 20 milliliters of ammonium chloride to mix saturated solution, then add 20 milliliters of ammonia water, then dilute to scale with distilled water and mix;

[0029] (2), filter in the 100 milliliter beaker with fast filter paper, discard 10 milliliters of initial filtrates when filtering;

[0030] (3) Use a 20 ml pipette to take 20 ml of the filtrate into a 250 ml conical flask, add 1 drop of xylenol orange solution to the conical flask, and then adjust it to yellow with 1:1 hydrochloric acid;

[0031] (4), add 0.3g of solid ascorbic acid, and then adjust to red with 1:1 ammonia water;

[0032] (5), then add 20 milliliters of sodium thiosulfate solutions of 200g / L and 20 milliliters of aceti...

no. 2 example

[0035] The present embodiment is the second example of the rapid detection solution zinc content method of the present invention, comprises the following steps:

[0036] (1), take 5 milliliters of zinc powder purification solution samples to 100 milliliter volumetric flasks, and add 20 milliliters of ammonium chloride to mix saturated solution, then add 20 milliliters of ammonia water, then dilute to scale with distilled water and mix;

[0037] (2), filter in the 100 milliliter beaker with fast filter paper, discard 10 milliliters of initial filtrates when filtering;

[0038] (3) Use a 20 ml pipette to take 20 ml of the filtrate into a 250 ml conical flask, add 1 drop of xylenol orange solution to the conical flask, and then adjust it to yellow with 1:1 hydrochloric acid;

[0039] (4), add 0.4g of solid ascorbic acid, and then adjust to red with 1:1 ammonia water;

[0040] (5), then add 20 milliliters of sodium thiosulfate solutions of 200g / L and 20 milliliters of acetic acid...

no. 3 example

[0043] This embodiment is the third example of the method for rapid detection of zinc content in solution according to the present invention, comprising the following steps:

[0044] (1) Take 5 milliliters of the pre-indium extraction solution sample into a 100 milliliter volumetric flask, add 20 milliliters of ammonium chloride to mix the saturated solution, then add 20 milliliters of ammonia water, then dilute to the mark with distilled water and mix well;

[0045] (2), filter in the 100 milliliter beaker with fast filter paper, discard 10 milliliters of initial filtrates when filtering;

[0046] (3) Use a 20 ml pipette to take 20 ml of the filtrate into a 250 ml conical flask, add 1 drop of xylenol orange solution to the conical flask, and then adjust it to yellow with 1:1 hydrochloric acid;

[0047] (4), add 0.5g of solid ascorbic acid, and then adjust to red with 1:1 ammonia water;

[0048] (5), then add 20 milliliters of sodium thiosulfate solutions of 200g / L and 20 mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com