External rotor electronically controlled fan and its speed regulation method

An external rotor fan, electronic control technology, used in pump control, mechanical equipment, non-variable-capacity pumps, etc., can solve the problems of small heat dissipation, poor heat dissipation effect, inapplicability, etc., to achieve dustproof sealing and ensure reliability. The effect of low work and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

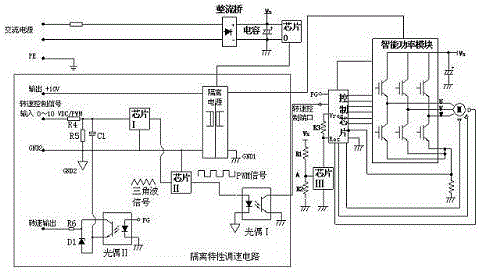

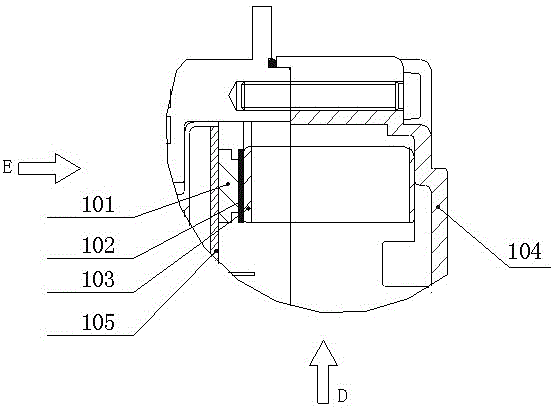

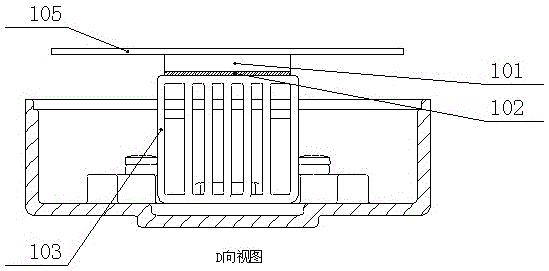

[0032] Embodiment 1: with reference to attached figure 1 . An electronically controlled outer rotor fan, including an outer rotor fan, the speed regulation circuit of the outer rotor fan includes an AC-direct power conversion circuit, an isolation characteristic speed regulation circuit, an overvoltage protection circuit and an intelligent power control module; the isolation characteristic speed regulation circuit The power output terminal of the isolated power supply outputs +10V power supply, the ground terminal GND2 of the isolated power supply is connected to the ground terminal of the operational amplifier chip Ⅰ, the ground terminal of the comparator chip Ⅱ, the signal output terminal of the optocoupler Ⅱ, the negative pole of capacitor C1, and the negative pole of diode D1. The positive pole of capacitor C1 is connected to the signal input terminal of the operational amplifier chip Ⅰ, the positive pole of diode D1 is connected to the speed output terminal, the signal in...

Embodiment 2

[0038] Embodiment 2: On the basis of Embodiment 1, a speed regulation method for the drive circuit of an external rotor electronically controlled fan, using the AC / DC conversion chip 0 to generate power with isolation characteristics for the operational amplifier chip I and the comparator chip Ⅱ provides working power, and the triangular wave signal generated by the operational amplifier chip Ⅰ enters the comparator chip Ⅱ for signal processing to generate a PWM signal, which is then connected to the speed control port of the fan control chip through the optocoupler Ⅰ to realize the speed regulation function , the fan speed signal FG is fed back to the fan user power system in real time through the optocoupler II; the voltage detection circuit is used to detect the VS voltage at the intelligent power control module terminal in real time, when the VS voltage at the intelligent power control module terminal rises, the comparator chip III signal input The voltage at point A of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com