Driving circuit and driving method of external rotor electronic control type fan adjuster

An electronic control and drive circuit technology, applied in machine/engine, pump control, mechanical equipment, etc., can solve problems such as inability to achieve isolated speed regulation, no overvoltage protection, and easy burnout of the fan power supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

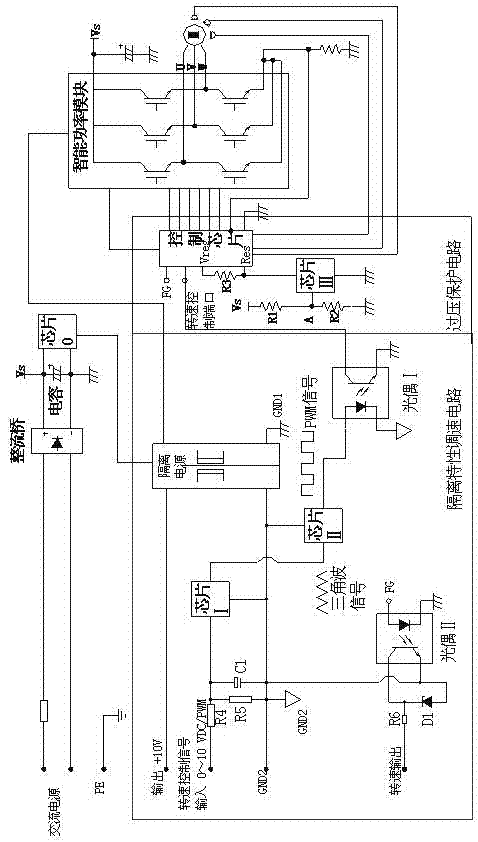

[0011] Embodiment 1: with reference to attached figure 1 . An external rotor electronically controlled fan regulator drive circuit is composed of an isolation characteristic speed regulation circuit and an overvoltage protection circuit; the power output terminal of the isolated power supply in the isolation characteristic speed regulation circuit outputs +10V power supply, and the ground terminal GND2 of the isolation power supply Connect to the ground terminal of operational amplifier chip Ⅰ, the ground terminal of comparator chip Ⅱ, the signal output terminal of optocoupler Ⅱ, the negative pole of capacitor C1, the negative pole of diode D1, the positive pole of capacitor C1 is connected to the signal input terminal of operational amplifier chip Ⅰ, and the positive pole of diode D1 is connected to the speed Output terminal, the signal input terminal of the optocoupler II is connected to the FG signal terminal, the signal terminal of the isolated power supply is connected t...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, a driving method for an external rotor electronically controlled fan regulator drive circuit, using AC / DC conversion chip 0 to generate power with isolation characteristics for operational amplifier chip I and comparator chip Ⅱ provides working power, and the triangular wave signal generated by the operational amplifier chip Ⅰ enters the comparator chip Ⅱ for signal processing to generate a PWM signal. To realize the speed regulation function, the fan speed signal FG is fed back to the fan user power system in real time through the optocoupler II; the voltage detection circuit is used to detect the rectified DC voltage VS at the intelligent power control module terminal in real time, when the rectified DC voltage VS at the intelligent power control module terminal When it rises, the voltage at point A of the signal input terminal of the comparator chip III also rises accordingly. When the rectified DC voltage VS at the intellig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com