Superfine suede fiber leather and preparation method thereof

A microfiber leather, microfiber technology, applied in chemical instruments and methods, synthetic resin layered products, textiles and papermaking, etc., can solve the problem of low tear strength and peel strength, uneven surface, transfer film Insufficient bonding and other problems, to achieve the effect of high peel strength, high tear resistance and rich color layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

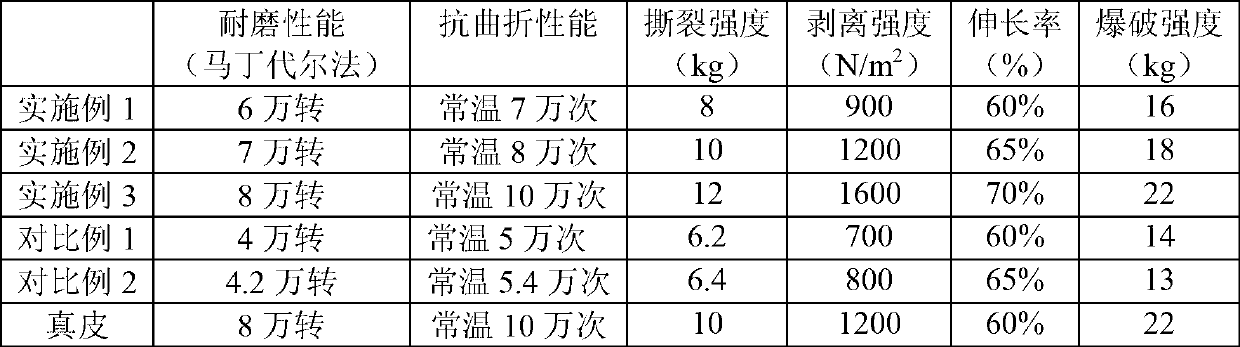

Examples

preparation example Construction

[0016] The invention provides a method for preparing suede superfine fiber leather, which comprises the following steps: setting a suede superfine fiber base; printing layer; and laminating the high-solid pattern, peeling off after cooling to obtain suede microfiber leather; wherein, the solid content of the polyurethane resin slurry used to form the high-solid printing layer is 42% to 50%, The viscosity is 3000pa·s~6000pa·s.

[0017] In the prior art, in order to obtain suede microfiber leather with high tear and peel strength, researchers have made various choices in the selection of suede microfiber base and transfer film, hoping to find more suitable materials; Or various adjustments are made to the temperature, pressure or time of printing when forming the bonding layer, in order to expect to obtain suede microfiber leather with better wear resistance, high tear and peel strength. The present invention creatively uses polyurethane resin slurry with a solid content of 42%...

Embodiment 1

[0032] Set a 0.8mm thick suede ultra-fine bottom blank, use polyurethane resin with a solid content of 50% and a viscosity of 6000pa·s for pulping, use acetone as a solvent, and add leather pigment color chips during the pulping process to obtain Polyurethane resin slurry with a solid content of 44% and a viscosity of 3500pa·s.

[0033] Adjust the gap between the high-solid printing wheel and the rubber roller to make it 0.1mm smaller than the thickness of the suede microfiber bottom blank, transfer the polyurethane resin slurry to the suede superfine fiber bottom blank through the high-solid printing wheel, and Pass through an oven at 100° C. at a speed of 7 m / min to obtain a high-solid printing layer with patterns or patterns.

[0034] Adjust the pressure of the laminating mirror roller to 3MPa, and the temperature is 100°C. The gap between the laminating mirror roller and the rubber roller is 0.1mm smaller than the thickness of the suede microfiber bottom blank. After the l...

Embodiment 2

[0036] Set a 1.1mm thick suede ultra-fine bottom blank, use polyurethane resin with a solid content of 55% and a viscosity of 7000pa·s for pulping, use acetone as a solvent, and add leather pigment color chips during the pulping process according to customer needs , to obtain a polyurethane resin slurry with a solid content of 46% and a viscosity of 4500 Pa·s.

[0037] Adjust the gap between the high-solid printing wheel and the rubber roller to make it 0.15mm smaller than the thickness of the suede microfiber bottom blank, transfer the polyurethane resin slurry to the suede superfine fiber bottom blank through the high-solid printing wheel, and Pass through an oven at 110° C. at a speed of 7 m / min to obtain a high-solid printing layer with patterns or patterns.

[0038] Adjust the pressure of the laminating mirror roller to 4MPa, and the temperature is 110°C. The gap between the laminating mirror roller and the rubber roller is 0.15mm smaller than the thickness of the suede m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com