Household garbage coupling fluidized bed hierarchical pyrolytic gasifier

A fluidized bed and entrained bed technology, applied in the field of environmental protection equipment, can solve problems such as difficult phenol water, high utilization rate of waste resources, and low gas calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

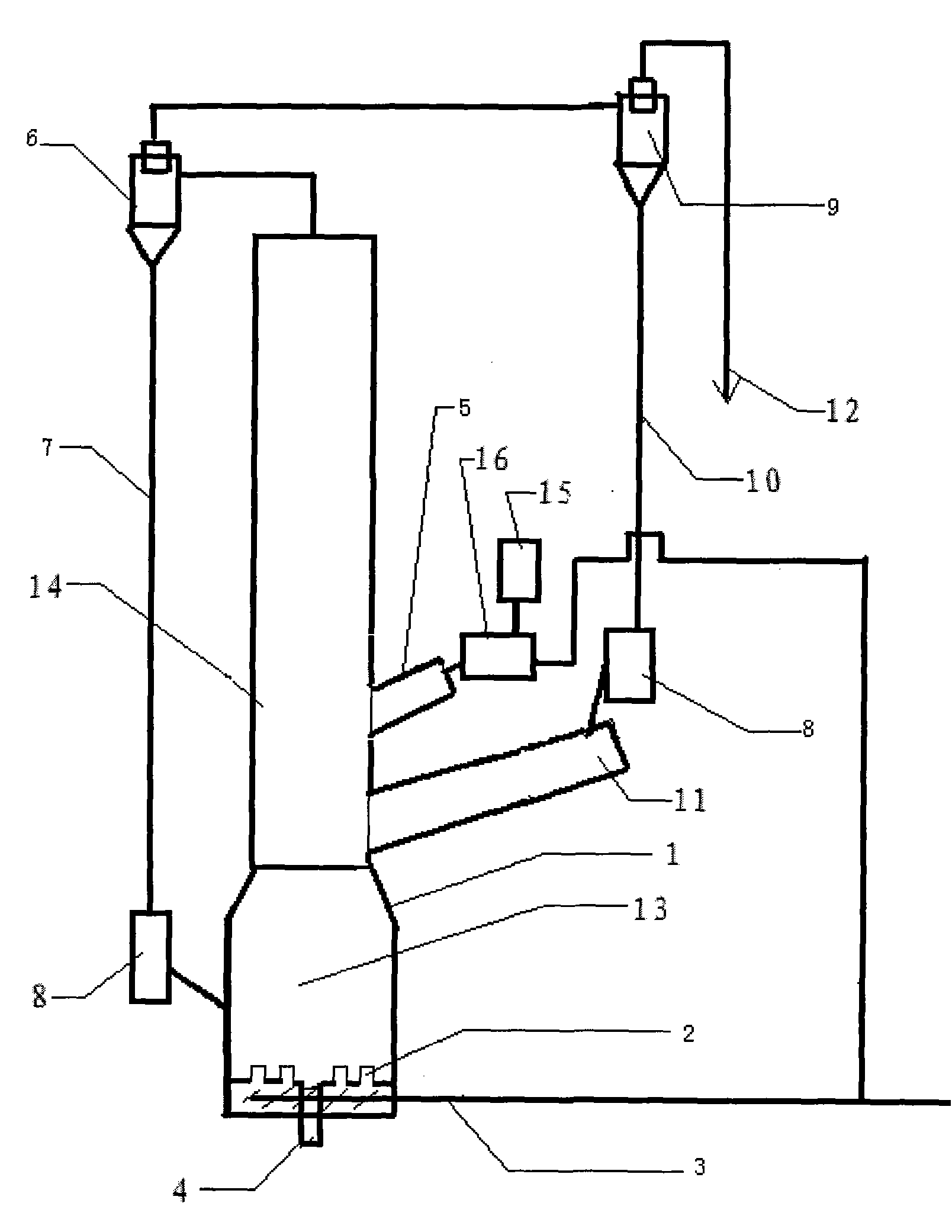

[0017] The domestic waste coupled fluidized bed graded pyrolysis gasifier consists of a deironing pulverizer (15), a sleeve type tumble dryer (16), a coupled fluidized bed (1), a gas distributor (2), and an air inlet pipe ( 3), ash discharge pipe (4), pulverized coal feed port (5), primary gas-solid separator (6), coarse ash circulation return pipe (7), return device (8), secondary gas-solid separator Composed of separator (9), fine ash circulation return pipe (10), entrained flow bed (11), gas outlet (12), it is characterized in that the front end of coupling fluidized bed (1) is provided with iron removal pulverizer (15) successively ) and casing type tumble dryer (16), the bottom of coupled fluidized bed (1) is provided with gas distributor (2), air inlet pipe (3) and ash discharge pipe (4), and the bottom of gas distributor (2) An air inlet pipe (3) is provided, and the ash discharge pipe (4) is arranged in the center or triangular distribution of the gas distributor (2); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com