High-flame-retardation chloroprene rubber sealing gasket and its preparation method

A technology of neoprene and gaskets, which is applied in the field of gaskets, can solve problems such as burning, and achieve the effects of improving flame retardancy and corrosion resistance, small friction coefficient, and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

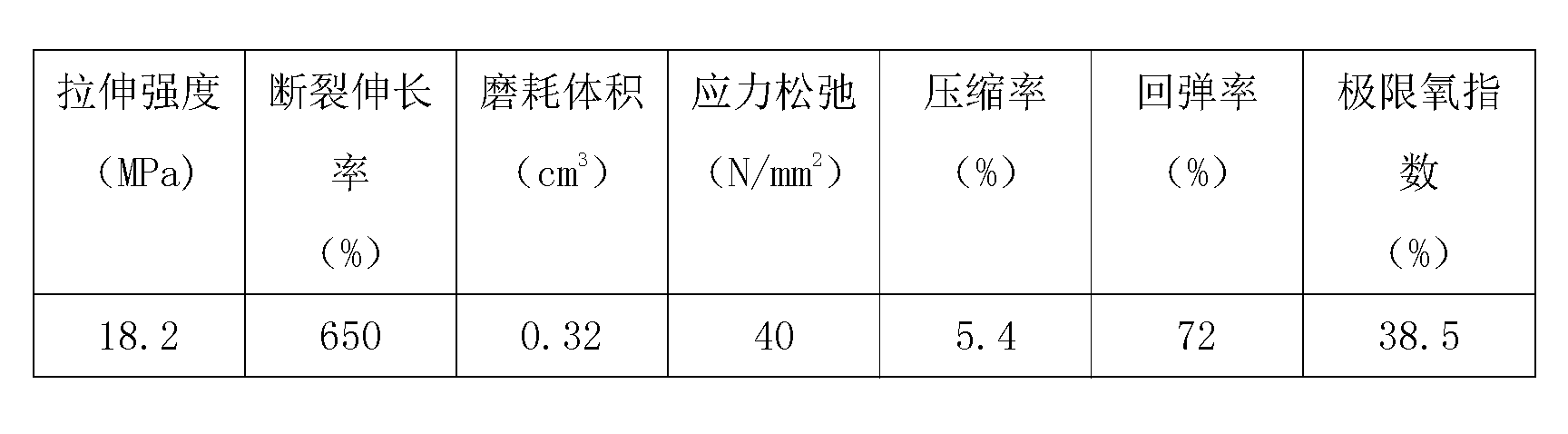

[0015] A kind of highly flame-retardant chloroprene rubber gasket, the parts by weight of its composition raw material are: 140 parts of chloroprene rubber CR121, Butyl rubber CBK139 12 parts, 22 parts of chlorohydrin rubber H75, 16 parts of SG-5 type PVC resin, 4 parts of acetyl citrate tris (2-ethylhexyl) ester, 4 parts of epoxy tetrahydrophthalate dioctyl ester, decyl 2 parts of diacid propylene glycol polyester, Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 2 parts, 1.5 parts of sulfur, 4 parts of zinc oxide, 2 parts of calcium stearate, 1 part of zinc stearate, 8 parts of zinc borate, 36 parts of nano attapulgite, 42 parts of nano sepiolite, 30 parts of nano silicon dioxide 15 parts of carbon black N339, 8 parts of precipitated silica, 1.5 parts of aluminate coupling agent DL-411, 0.6 parts of anti-ultraviolet agent, 1.6 parts of crosslinking agent TAIC, 3-aminopropyltrimethoxysilane 1.5 parts, 1.5 parts of anti-aging agent OD, 1 part of anti-aging agent ODA, 1.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com