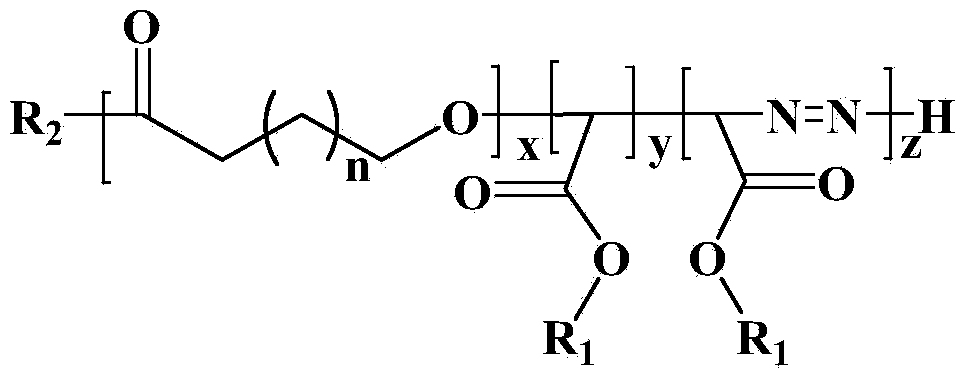

Terpolymer of diazoacetate, carbethoxy cabbeen and cyclic lactone and preparation method thereof

A technology of diazoacetate and ethoxycarbonylcarbene, which is applied in the field of copolymerization of diazoacetate and cyclic lactone, can solve problems such as destruction, waste of resources and the environment, and the method is simple and convenient, and the preparation is simple, convenient and rapid The effect of compositing paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

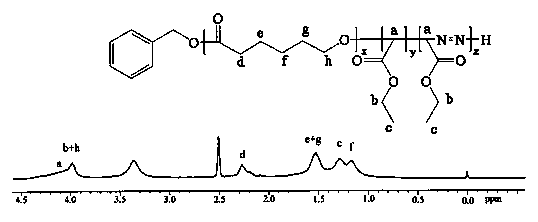

Embodiment 1

[0027] Under the protection of argon, 0.0001 mol of benzyl alcohol as an initiator, 0.01 mol of ethyl diazoacetate and 0.01 mol of ε-caprolactone were irradiated by 200 watts of microwave for 120 minutes. The resulting product was reprecipitated from tetrahydrofuran / methanol. Removal of the organic solvent in vacuo yields the polymer. The molecular weight of the obtained polymer was 36100, the yield was 24.61%, and the nitrogen content was 1.38%.

Embodiment 2

[0029] Under the protection of argon, 0.0001 mol of benzyl alcohol as an initiator, 0.01 mol of ethyl diazoacetate and 0.01 mol of δ-valerolactone were irradiated by 200 watts of microwave for 120 minutes. The resulting product was reprecipitated from tetrahydrofuran / methanol. Removal of the organic solvent in vacuo yields the polymer. The molecular weight of the obtained polymer was 1500, the yield was 29.45%, and the nitrogen content was 4.17%.

Embodiment 3

[0031] Under nitrogen protection, 0.0001 mol of benzyl alcohol was used as an initiator, 0.01 mol of ethyl diazoacetate and 0.01 mol of γ-butyrolactone were irradiated by 200 watts of microwave for 300 minutes. The resulting product was reprecipitated from tetrahydrofuran / methanol. Removal of the organic solvent in vacuo yields the polymer. The molecular weight of the obtained polymer was 2100, the yield was 26.20%, and the nitrogen content was 5.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com