Styrene-acrylic latex for surface coating and its preparation method and application

A technology of styrene-acrylic latex and surface coating, which is applied in coatings, paper coatings, textiles and papermaking, etc. It can solve the problems of low-temperature film-forming properties, anti-back tackiness and poor adhesion, and achieve coating gloss improvement, The effect of improving the surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

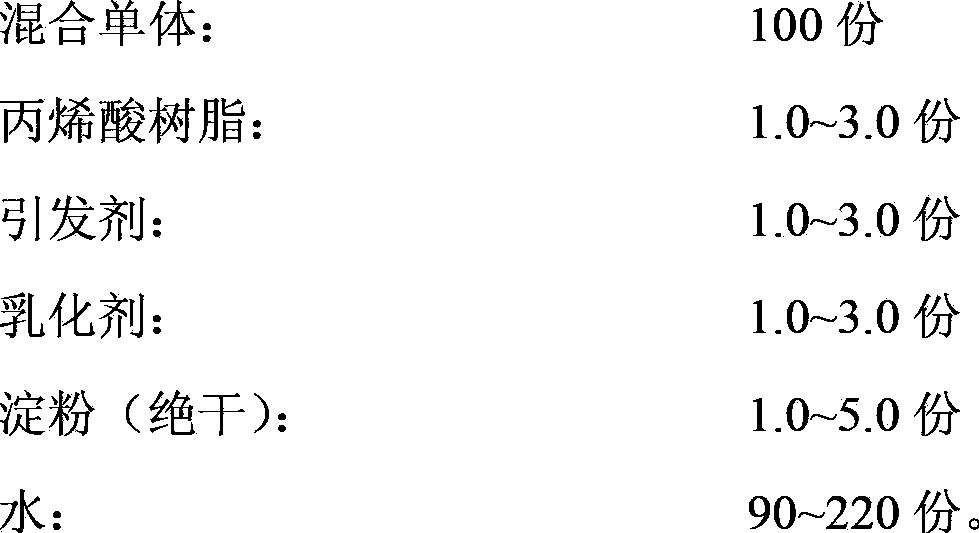

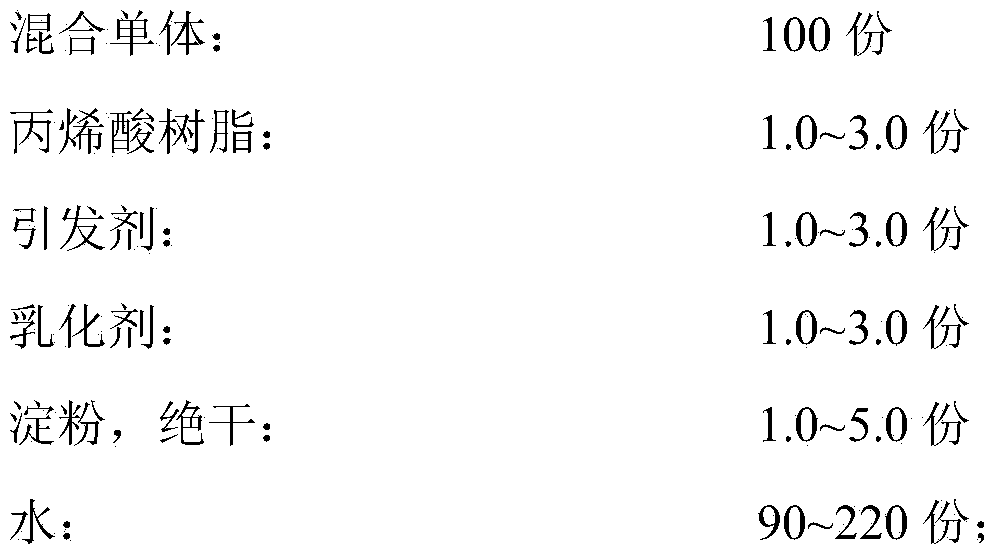

Method used

Image

Examples

Embodiment 1

[0029] Mix 0.6 g of potassium persulfate, 0.3 g of sodium lauryl sulfate, 0.1 g of anhydrous pear alcohol trioleate, 40 g of water and 55 g of mixed monomers (50 parts of butyl methacrylate, 43 parts of styrene, 7 parts of acrylic acid), stir to obtain homogeneous emulsion A, set aside.

[0030] 1.5 grams of acrylic resin (acid value 150mgKOH / g, molecular weight 2000), 1.4 grams of potassium persulfate, 0.45 grams of sodium lauryl sulfate, 0.15 grams of anhydrous trioleate, 45 grams of mixed monomers ( 50 parts of butyl methacrylate, 48 parts of styrene, 2 parts of acrylic acid) and 125 grams of water were added to a 1000mL four-necked flask with condenser, stirrer, thermometer and dripping device, stirred and heated to 60℃, reaction 1 Hours; then add homogeneous emulsion A within 1.5 hours, keep it at 70°C for 2 hours, then add 42 grams of 7% by weight oxidized tapioca starch aqueous solution, continue the reaction for 50 minutes, cool to 25°C, and use 15 % Sodium hydroxide aqu...

Embodiment 2

[0032] 0.3 g of ammonium persulfate, 0.4 g of sodium succinate sulfonate, 0.2 g of sorbitan trioleate, 7 g of water and 60 g of mixed monomers (65 parts of ethyl methacrylate, 30 parts of styrene, 5 parts of acrylic acid), stir to obtain homogeneous emulsion A, set aside.

[0033] Mix 2 g acrylic resin (acid value 100mgKOH / g, molecular weight 2500), 0.7 g ammonium persulfate, 0.93 g sodium succinate sulfonate, 0.465 g anhydrous trioleate, 40 g mixed monomer ( 75 parts of ethyl methacrylate, 20 parts of styrene, 5 parts of acrylic acid) and 133 grams of water were added to a 1000mL four-necked flask with condenser, stirrer, thermometer and dripping device, stirred and heated to 70°C, reacted 0.5 Hours; then add the homogeneous emulsion A within 2 hours, keep it at 80°C for 1.5 hours, add 25 grams of 8% weight concentration of hydroxypropyl starch aqueous solution, continue the reaction for 0.5 hours, reduce the temperature to 30°C, and use The 20% potassium hydroxide aqueous solu...

Embodiment 3

[0035] Combine 0.2 g sodium persulfate, 0.36 g sodium lauryl diphenyl ether disulfonate, 0.36 g dibenzyl cumyl phenol polyoxyethylene ether, 20 g water and 75 g mixed monomer (40 parts butyl acrylate Ester, 50 parts styrene, 10 parts methacrylic acid), stir to obtain homogeneous emulsion A, ready for use;

[0036] 1.0 g acrylic resin (acid value 80mgKOH / g, molecular weight 1000), 0.8 g sodium persulfate, 0.24 g sodium dodecyl diphenyl ether disulfonate, 0.24 g dibenzyl cumyl phenol polyoxygen Vinyl ether, 25 grams of mixed monomers (40 parts of butyl acrylate, 50 parts of styrene, 10 parts of methacrylic acid) and 30 grams of water were put into a 1000 mL four-necked flask with condenser, stirrer, thermometer and dropping device , Stir and warm to 60°C, react for 1 hour; then add the homogeneous emulsion A dropwise within 1 hour, keep it at 70°C for 2.0 hours, then add 50 grams of 10% starch acetate aqueous solution by weight, and continue the reaction for 0.5 After hours, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com