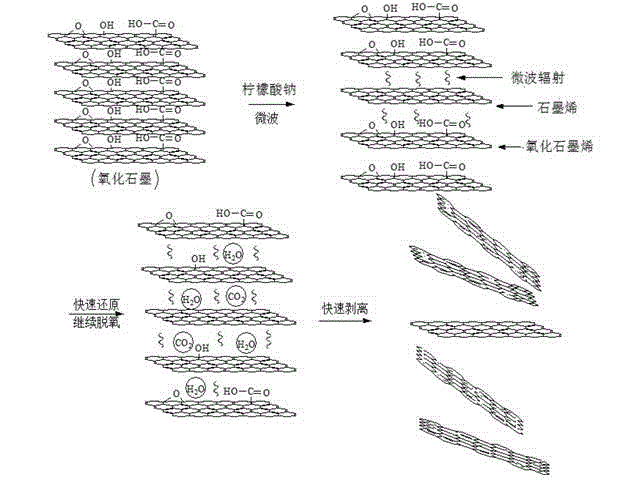

Microwave-assisted method for preparing graphene through reduction of sodium citrate

A sodium citrate, microwave-assisted technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., to achieve uniform heating, increase reaction rate, and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Disperse 0.05g of graphite oxide prepared by the improved Hummers method in 200ml of deionized water, ultrasonically disperse at a power of 210~300W for 40~80min, add 1g of sodium citrate, stir evenly, and place in a microwave oven with a rated output power of 1000W In the reactor, set the reaction temperature at 70-95°C, react at a stirring rate of 600rpm / min for 60s-150s, cool to room temperature, and then centrifuge at a centrifugation rate higher than 13000rpm / min for more than three times, and freeze the black solid in the lower layer Just dry.

Embodiment 2

[0027] Disperse 0.1g of graphite oxide prepared by the improved Hummers method in 200ml of deionized water, ultrasonically disperse at a power of 210~300W for 40~80min, add 5g of sodium citrate, stir evenly, and place in a microwave oven with a rated output power of 1000W In the reactor, set the reaction temperature at 70-95°C, react at a stirring rate of 600rpm / min for 60s-150s, cool to room temperature, and then centrifuge at a centrifugation rate higher than 13000rpm / min for more than three times, and freeze the black solid in the lower layer Just dry.

Embodiment 3

[0029] Disperse 0.2g of graphite oxide prepared by the improved Hummers method in 200ml of deionized water, ultrasonically disperse at a power of 210~300W for 40~80min, add 10g of sodium citrate, stir evenly, and place in a microwave oven with a rated output power of 1000W In the reactor, set the reaction temperature at 70-95°C, react at a stirring rate of 600rpm / min for 60s-150s, cool to room temperature, and then centrifuge at a centrifugation rate higher than 13000rpm / min for more than three times, and freeze the black solid in the lower layer Just dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com